- 384 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Specialist yarn, woven and fabric structures are key elements in the manufacturing process of many different types of textiles with a variety of applications. This book explores a number of different specialist structures, discussing the developments in technology and manufacturing processes that have taken place in recent years.With its distinguished editor and international team of contributors, Specialist yarn, woven and fabric structures is essential reading for all textile researchers, technicians, engineers and technologies, and will also be suitable for academic purposes.

- Looks at developments that have occurred in the manufacturing of specialist yarn, weave and fabric structures

- Discusses different types of specialist yarn structures, such as hybrid, fancy and compound yarns

- Offers insight into multicomponent fabric structures such as 3D nonwovens, flocked, knotted and jacquard woven fabrics

Information

1

Compound yarns

T. Chen, Soochow University, China

Abstract:

Compound yarns (core-spun yarns) have attractive development prospects because compound yarns combine the advantages of both core and wrapping fibres. This chapter will introduce compound yarns. It first reviews types of compound yarns – elastomer core, polyester core and worsted core. It then describes production methods for compound yarns – conventional ring spinning systems and the Siro spinning system. Finally applications and future trends for compound yarns are discussed.

Key words

compound yarn

core-spun yarn

yarn types

ring spinning

Siro spinning

1.1 Introduction

With the rise in living standards, consumers have been paying more attention to the functionalities and diversifications of textile products, and the diversity of yarn types is expected to increase. Nowadays, new raw materials and new technologies continue to come up, among which compound yarns (core-spun yarns) have attractive development prospects because compound yarns combine the advantages of both core and wrapping fibres. Compound spinning technologies are beneficial both to the improvement of spinning technology and to changes in structures, styles and properties. In this chapter, compound yarns will be introduced. In Section 1.2, types of compound yarns will be given, including elastomer core, polyester core and worsted core. In Section 1.3, production methods for compound yarns will be described, including the conventional ring spinning systems and the Siro spinning system. In Section 1.4, applications of compound yarns will be shown with examples. In Section 1.5, future trends for compound yarns will be discussed.

1.2 Types of compound yarns

Compound yarns (core-spun yarns) are yarns that have a central core with a second layer or sheath of fibres wrapped around it. The filament or strand of fibres confined mainly on the yarn axis is named as the ‘core filament’ or ‘core yarn’. Fibres wrapped around the core are called the ‘wrapping fibres’. There is a distinct boundary between the core and the wrapping. However, the core and wrapping integrate tightly so that fibres will not strip or slip during processing or use. The core and wrapping may either be of the same fibre type, or two different types (or more) may be used. Furthermore, one part may be of filament fibres while the other is of staple fibres; or both parts may be of either filament or staple fibres. According to the fibre type used, compound yarns can be divided into elastomer core, polyester core and worsted core.

1.2.1 Compound yarns with elastomer core

Elastomers are elastic, rubberlike substances. All elastomers are characterized by extremely high elongation – at least 200%, and frequently between 500 and 800% – and excellent elastic recovery. The point of introducing elastomers into yarn manufacturing is to achieve elastomeric yarns or stretch yarns. The most widely used elastomeric fibre, as the core of compound yarns, is polyurethane fibre. Polyurethane fibre is defined as a synthetic fibre in which the fibre-forming substance is a long-chain synthetic polymer comprised of at least 85% segmented polyurethane. Polyurethane fibre is known as ‘spandex’ in the USA, whereas fibre manufacturers in Western Europe prefer the name ‘elastane fibre’ (EL). Polyurethane fibre was developed by the Bayer Company in the 1930s. Plans for volume production and the trade name Lycra were announced by the DuPont Company in late 1959 (Wang et al., 2004).

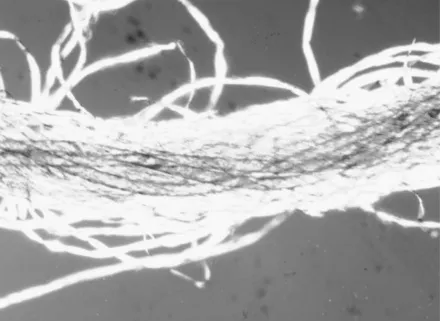

One of the most common types of core-spun yarns is the elastomer core-spun yarn, which involves a core of elastomeric fibre such as polyurethane fibre with a covering of staple fibres. Figure 1.1 shows the longitudinal morphology of a polyurethane core-spun yarn. It can be found from Fig. 1.1 that polyurethane core-spun yarn has the same appearance as the wrapping staple fibres. The core filament is wrapped closely in the staple fibres. Both the core filament and the wrapping staple fibres have the same twist. Because the wrapping staple fibres migrate around the core filament during the spinning process, the core filament is unexposed even when the core-spun yarn is under tension.

Fig. 1.1 Longitudinal morphology of a polyurethane core-spun yarn.

The wrapping staple fibres (cotton, wool and other natural fibres) give the polyurethane core-spun yarn good moisture absorption and hand. The yarn has excellent elastic recovery that can be altered up to 20% according to different end uses, which is far beyond the elasticity of the wrapping staple fibres. Since the core filament is unexposed, the yarn is easily dyed, even with deep colours.

Because polyurethane fibre is a low-strength high-extension type fibre, it destroys the cohesion among the staple fibres, and so the strength of the core-spun yarn decreases. Therefore, using polyurethane fibre makes no contribution to the yarn strength. And with higher polyurethane fibre content, the yarn strength will decrease. In general, the strength of the polyurethane core-spun yarn is about 80~90% of that of wrapping staple fibre yarn with the same specifications (Davies, 1997). When the core-spun yarn is under tension, the wrapping staple fibres break first; the core-spun yarn is only as strong as the wrapping staple fibres. So when the core-spun yarn has the same specifications as the yarn formed by the wrapping staple fibres, the strength of the core-spun yarn is lower.

1.2.2 Compound yarns with polyester core

Polyester was the second synthetic fibre type to be developed (1941) and is now by far the most widely used synthetic fibre, due to a balance of properties that gives it great versatility, and a less expensive manufacturing process compared with nylon. Polyester has good strength and abrasion resistance compared with nylon and also takes a permanent heat set – all ‘first-class’ fibre properties from the point of view of performance. Further characteristics that make polyester more popular than nylon are good resilience (the nearest to wool of any chemical fibre) and high modulus: these mean that it is springy and can recover well from strain, yet resists stretching better than nylon. Polyester also conducts moisture away from the skin better than nylon, dries faster, and is suppler in cold conditions. The compound yarns with the polyester core are manufactured precisely to create their high strength and shrink-proof qualities (Sawhney and Folk, 1992).

The longitudinal morphology of polyester core-spun yarn is similar to that of polyurethane core-spun yarn. Figure 1.2 is a schematic diagram of a cross-section of a polyester core-spun yarn. As the figure illustrates, the cross-section of the polyester core-spun yarn is not quite circular and the core filaments are not always in the geometrical centre of the yarn. Because of fibre migration during twisting, a few core filaments migrate to the sheath and some wrapping staple fibres migrate to the core. However, these minor migrations will not affect the appearance or wearing properties of core-spun yarn.

Fig. 1.2 Schematic diagram of the cross-section of a polyester core-spun yarn.

The wrapping fibres can be cotton, wool, rayon, Tencel, Modal, or other fibres. The core-spun yarns combine the advantages of a polyester (core) such as high strength, large elongation rate, limited unevenness and easy care with such advantages of natural or man-made staple (wrapping) fibres as moisture regain, heat retention, softness, comfort, pilling resistance and antistatic. And the weavability of core-spun yarns is better than that of filaments. A reasonable configuration of the ratios of core and wrapping fibres will lower material and production costs.

1.2.3 Compound yarns with worsted core

Nowadays, the development trend of woollen textiles is towards finer and lighter fabrics. The use of new yarn structures provides an effective solution. A compound yarn with a worsted core is one of the new yarn structures. Worsted core spinning can break through the count limit of the traditional wool spinning process by changing the yarn structure to achieve finer and lighter wool fabrics. Worsted core spinning uses a filament yarn and a wool roving, which are fed separately and kept a fixed distance from the nip of the front drafting roller, and they make up a triangular zone that is twisted together to form worsted core-spun yarn (Dong, 2004).

Figure 1.3 shows the cross-section of a worsted core-spun yarn. As can be seen, the cross-section is roughly circular. The wool fibre strand is wrapped in filaments with circular or curved shapes. There are few migrations between wool fibres and filaments. The reason is as follows....

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Textiles

- Chapter 1: Compound yarns

- Chapter 2: Developments in hybrid yarns

- Chapter 3: Developments in rope structures and technology

- Chapter 4: Developments in fancy yarns

- Chapter 5: Developments in 3D knitted structures

- Chapter 6: Developments in leno-weave fabrics

- Chapter 7: Developments in triaxial woven fabrics

- Chapter 8: Interwoven fabrics and their applications

- Chapter 9: Pile carpets

- Chapter 10: Developments in Jacquard woven fabrics

- Chapter 11: Developments in 3D nonwovens

- Chapter 12: Flocked fabrics and structures

- Chapter 13: Knotted fabrics

- Chapter 14: Developments in braided fabrics

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Specialist Yarn and Fabric Structures by R H Gong in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.