1.1 Introduction

The assembly of modern electronic components started in the early 1960s, after the emergence of the integrated circuit in the 1950s. However, all the early electronic components were connected by metallic systems such as solder (e.g. tin–lead), and wire bonding (gold and aluminium), and were mounted on ceramic substrates up until the 1980s. In fact, most of the applications for electronic systems at this time were for high-reliability applications such as defence and were not driven by cost. With the introduction of electronics into consumer products, polymeric substrates and adhesives started to attract attention because of their low cost and high production throughput. In fact, polymer adhesives are now considered as invaluable materials for modern- day, low-cost miniaturized consumer electronic products. However, the introduction of polymers and adhesives in the packaging of semiconductors results in a number of manufacturing and reliability problems. Outgassing, ion contamination, void/air entrapment, moisture absorption, CTE (coefficient of thermal expansion) mismatch and related thermal stress are some of the notorious problems that have had to be addressed by polymer experts and electronic packaging engineers over the last few decades. Therefore, polymer adhesive technology (both materials and their processing) has improved significantly during that period. Because of the tremendous growth of the consumer electronics, adhesive technology is now a multi-billion pound business, fuelling continuous R&D efforts from both industry and academia.

Adhesives are used as both functional and structural materials in electronic packaging. They provide electrical connections, thermal paths for extracting heat away from a semiconductor, and can be used to provide structural integrity of the package and system. They are applied as either paste or a solid film. Bare chips, single-chip packages, and multi modules can all be attached on the plastic printed circuit board (PCB) by adhesives without any soldering or wiring. Some of the advanced adhesives are used in flexible PCBs, optoelectronics, and sensors, as well as in smart cards. This book is dedicated to advanced adhesives that have attracted attention from the electronic packaging community. This chapter aims to introduce the various types of adhesives used in electronic packaging, along with a brief introduction to electronic assemblies and the uses of adhesives in electronics.

1.2 Classification of adhesives used in electronic packaging

Adhesives used to package electronic components are classified based on (i) their physical form such as pastes or films, (ii) chemical type such as epoxies, acrylics or polyimides, (iii) molecular structure such as thermoplastic or thermosetting, (iv) curing method such as heat curable, uv-curable, (v) function such as electrical adhesives, thermal adhesives, and (vi) application such as die attach, underfill adhesive.

Interestingly, the same adhesive can be termed differently, based on its various classifications, and sometimes it is desirable to mention all kinds of classification while describing an adhesive. For example, Anisotropic Conductive Adhesive (ACA) is a film-type (physical form), epoxy-based (chemical formulation), thermosetting (molecular structure), heat-curable (curing method) adhesive used in electronics.

While this book is dedicated to such advanced adhesives, a very brief classification of all adhesives used in electronics is given in here.

1.2.1 Classification based on physical form

All adhesives used in electronics can be applied either as a paste or a film. Pastes are semi-solid materials that are usually screen printed or stencil printed. Sometimes, they can be dispensed, even through a needle. Film adhesives are solid tapes that can be cut as required for the bonding area. Isotropic Conductive Adhesives (ICA) are generally used as pastes while Anisotropic Conductive Adhesives (ACA) are applied as films.

1.2.2 Classification based on chemical formulation

Adhesives are much more complicated than metals or ceramics. They are commonly referred to by their polymer type. The most common polymer type used in electronic adhesives is epoxy. The next is probably acrylic, then polyimide and then polyurethane, and so on. There are hundreds of formulations on each generic polymer in the market, with some proprietary additives.

1.2.3 Classification based on molecular structure

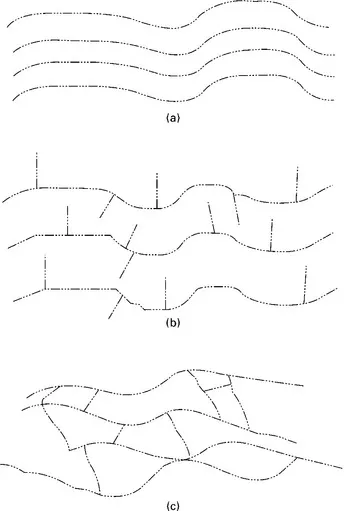

Polymer adhesives are broadly classified as thermoplastic, or thermosetting, depending on the molecular structure. Thermoplastics are linear polymers with either straight chains or branched chains (see Fig. 1.1a,b). They melt (liquefy) at a specific temperature and then resolidify on cooling; therefore they are easy to process and rework. Examples of thermoplastics are polyurethanes and polyamides. However, some linear polymer adhesives with aromatic or heterocyclic components in their structures possess high thermal stability and do not melt; instead, they decompose on further heating. Thermosetting adhesives become highly cross-linked polymers on curing (see Fig. 1.1c), and unlike thermoplastics, they will not then melt at any temperature. Therefore, they are not reworkable once they are cross-linked. Examples are epoxies, cyanate esters and phenolics.

1.1 Schematic of linear (thermoplastic) and cross-linked (thermosetting) polymer. (a) Straight chain structure; (b) branched chain structure; (c) cross-linked structure.

1.2.4 Classification based on curing process

There are various curing processes to give workable strength to adhesives. While dispensing the adhesive in its initial state, the molecular weight is low; therefore it is usually in a liquid state. However, during the curing process, molecules join together to form a three-dimensional network, leading to high molecular weight which increases the viscosity and finally forms a solid. Heat-curing is the most widely used and simplest method of polymerization. Curing kinetics are temperature- and time-dependent.1 For any polymer system, the kinetics’ parameters dictate the rate of curing at different temperatures. Final properties of the adhesive are directly related to the curing percentage of the polymer components. The curing profile is measured by monitoring the desired adhesive properties such as electrical resistivity, hardness, bond strength or dielectric constant, as a function of temperature and time. The degree of polymerization, i.e. curing percentage, can be measured by experimental techniques such as DSC (Differential Scanning Calorimetry), Thermomechanical Analysis (TMA) or FTIR (Fourier Transformed Infrared Spectroscopy).

Curing kinetics are mostly controlled by the added hardener (often called the catalyst) used in adhesive formulations. Short curing is desirable to increase the industrial throughput. Therefore, selecting a suitable hardener is important to cope with the mass production required for consumer electronics. Recently, snap-cured adhesives have been developed, which can be cured within a few seconds at relatively low temperatures.

Some adhesives polymerize in the presence of ultraviolet or even visible light, which makes them attractive for wider applications in heat-sensitive parts, especially in photonics packaging. They also show rapid curing. In certain cases, however, slight heat is required to complete the curing process. Chapter 8 describes this photo curing process and their uses in photonics.

Microwave curing is another rapid curing method that is attractive for its advantage in providing a uniform heating capability over a large section. However, unlike conventional microwaves, it uses Variable Frequency Microwaves (VFM) that rapidly vary the operating frequency. Swept frequencies generate a uniform energy distribution as well as reduced arcing of metal fillers and semiconduc...