eBook - ePub

Fashion Supply Chain Management Using Radio Frequency Identification (RFID) Technologies

- 256 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Fashion Supply Chain Management Using Radio Frequency Identification (RFID) Technologies

About this book

Fashion Supply Chain Management Using Radio Frequency Identification (RFID) Technologies looks at the application of RFID technologies in such areas as order allocation, garment manufacturing, product tracking, distribution and retail. As supply chains in the textiles and fashion industry become ever more complex and global, and as the shift to mass customization puts more pressure on a rapid and flexible response to customer needs, monitoring and improving supply chain efficiency in the industry becomes crucial. Radio frequency identification (RFID) technologies offer a unique opportunity to achieve these goals.

This book reviews the role of RFID technologies in the textiles and fashion supply chain to improve distribution, process management and product tracking, garment manufacturing, and assembly line operations. It also explores how RFID technologies can improve order allocation in the supply chain, and how these technologies can also be used for intelligent apparel product cross-selling. Its chapters also discuss measuring the impact of RFID technologies in improving the efficiency of the textile supply chain, and modeling the effectiveness of RFID technologies in improving sales performance in fashion retail outlets.

Fashion Supply Chain Management Using Radio Frequency Identification (RFID) Technologies is a comprehensive resource for academic researchers, industry managers, and professionals within the fashion industry.

- Looks at the application of RFID technologies in order allocation, garment manufacturing, product tracking, distribution, and retail

- Reviews RFID technologies in the textiles and fashion supply chain for improving distribution, process management and product tracking, garment manufacturing, and assembly line operations

- Focuses on measuring the impact of RFID technologies on efficiency, and modeling the effectiveness of RFID technologies in improving retail outlet sales

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Fashion Supply Chain Management Using Radio Frequency Identification (RFID) Technologies by Calvin Wong,Z. X. Guo in PDF and/or ePUB format, as well as other popular books in Business & Fashion & Textile Industry. We have over one million books available in our catalogue for you to explore.

Information

1

The role of radio frequency identification (RFID) technologies in the textiles and fashion supply chain: an overview

W.K. Wong, The Hong Kong Polytechnic University, Hong Kong

Z.X. Guo, Sichuan University, China

Abstract:

Barcode and radio frequency identification (RFID) technology have been widely applied in automatic identification and tracking throughout the textiles and fashion supply chain. This chapter will first compare the differences between these technologies and discuss how RFID technology can perform better than barcode technology in various aspects. The fundamentals of RFID technology, the architecture of an RFID system and an overview of the application of RFID technology in the textiles and fashion supply chain will be described.

Key words

barcode; radio frequency identification (RFID); system architecture; textiles and fashion supply chain

1.1 Introduction

The apparel industry is one of the most important sectors of the economy, creating jobs and products that meet fundamental human needs. The supply chain of the apparel industry is highly complex due to a number of distinct industrial features, which include short product life-cycles, a wide product range and volatile customer demand. It is becoming an increasing trend to employ radio frequency identification (RFID) technology to identify and track individual products in the apparel supply chain.

A supply chain is a set of policies, processes, management actions, and technologies that collectively forecast, acquire and deliver products and services to meet the identified needs of a company and/or customer (Shepard, 2005). Supply chain management (SCM) is the management of a network of interconnected business processes involved in a supply chain for the purpose of creating value for customers and stakeholders. It spans all movement and storage of raw materials, work-in-process inventory and finished goods. Effective SCM is crucial to lower operating costs and improve the competitiveness of businesses. Good SCM depends on the availability of accurate and timely data about various activities in the supply chain. These include progress in meeting production schedules, current inventory levels and the location of material. Data acquisition is thus crucial. For example, early detection of a shipment delay by rail may mean that it can still make its deadline by trucking it, while later detection of this problem may mean that some critical parts may have to be delivered by air, a much more expensive option.

In recent years, automatic identification systems have become popular in many manufacturing and service industries as well as the logistics industry, which aim to improve data acquisition processes and to capture data in a more timely and accurate manner. This in turn gives management and decision-makers more time to recognize potential problems and make efficient decisions. The application of automatic identification systems involves a broad range of supply chain operations, such as:

• item identification and tracking;

• manufacturing;

• retailing;

• transportation;

• warehousing; and

• payment transactions.

Technologies such as barcode, RFID, signature capture and magnetic stripe, the former two being most commonly used in logistics and SCM, are indeed already in use.

1.2 From barcode to RFID technology

A barcode is an optical machine-readable representation of data relating to the object to which it is attached. The invention of the barcode is usually credited to two graduate students at Drexel Institute of Technology, Norman Joseph Woodland and Bernard Silver, who pioneered the concept and filed the first patent on barcode technology on 20 October 1949. The first application of industrial barcode technology was in the labeling of railroad cars in the 1960s, but it was not commercially successful until the now ubiquitous Universal Product Code (UPC) barcode. This was developed and used to automate the grocery checkout process, the first occasion of which has been credited on a packet of chewing gum in Troy, Ohio, in 1974. The successful application of barcode technology revolutionized inventory tracking and management in the retail industry.

Nowadays, barcodes are used almost universally. Airlines rely on barcodes to track passenger luggage to reduce the chance of loss. Warehouses rely on them to track the movements of materials and parts. The express industry relies on them to track mails and parcels. Barcodes are attached to each book to make the borrowing, returning and stocktaking of books easier and faster. Researchers have also looked into insects’ mating habits, such as by placing tiny barcodes on individual bees. NASA depends on barcodes to monitor thousands of heat tiles that need to be replaced after every space shuttle trip. Barcodes even appear on humans! Stamping barcodes onto fashion models helps designers to coordinate their fashion shows.

Many different types of barcode technologies have been developed since the emergence of the UPC barcode, which can be classified mainly into two categories:

1. linear barcode;

2. two-dimensional (2D) barcode.

Each category comprises multiple barcode types. The linear barcode is made up of parallel lines and spaces of various widths that create specific patterns, which typically encodes alpha-numerical strings up to maximum of about 20 characters. The 2D barcode is made up of rectangles, dots, hexagons and other geometric patterns in two dimensions, which can represent more data per unit area than the linear barcode.

Although it is well developed and its applications are wide-ranging, barcode technology does have some limitations. For example, we are not able to change the data on a barcode once it is printed. In addition, barcode scanning devices are designed to operate over short distances. It is these limitations which RFID technology is capable of overcoming.

RFID is a generic term used to describe technologies that involve the use of a wireless non-contact system. This utilizes radio waves to transfer data from an RFID tag attached to an object, for the purposes of automatic identification and tracking. Unlike barcode technology, RFID tags can be read from up to tens of meters away and beyond the lines of sight of the reader. Although the history of radio frequency engineering can be traced back to 1864, when James Clerk Maxwell predicted the existence of electromagnetic waves through his famous equations, RFID was not invented until 60 years later. The first RFID application was developed in conjunction with radar technology for the Identification Friend or Foe (IFF) system used during World War II. The IFF system was developed in a secret British project led by Scottish inventor and physicist Sir Robert Alexander Watson-Watt. In this system, active and battery-powered RFID tags were placed on each British plane. When planes received radio frequency signals from radar stations on the ground, they broadcast signals back in the opposite direction which identified the plane as friendly. A passive radio transponder with memory, invented by Mario W. Cardullo and patented on 23 January 1973, is usually viewed as the first patent for an RFID tag. However, the first patent to be associated with the abbreviation RFID would not appear for a further ten years, this being granted to Charles Walton.

The applications of RFID technology have increased rapidly since its emergence. Nowadays, RFID can be used almost anywhere where a unique identification system is needed. The major areas of RFID applications involve:

• access control;

• personnel and product identification;

• fleet management;

• vehicle identification;

• production line monitoring;

• passport security;

• mail and shipping; and

• baggage handling.

1.3 Comparing barcode and RFID technologies

Both barcode and RFID technologies are used widely for automatic identification and tracking, and each fulfills this function efficiently and reliably. However, there exist significant differences between these two technologies:

• Barcode technology works by scanning a printed barcode label with barcode readers such as an optical laser, while RFID scans a tag using radio frequency signals. Barcodes do not work well in environments where barcode labels are prone to being wrinkled, dirty or smudged. These are common problems because the barcode labels have to be exposed on the outside of the product. However, RFID technology can perform well in these environments because RFID tags can be implanted within the product itself. This means the electronic components of RFID tags are better protected and can therefore offer greater ruggedness and reusability.

• Barcode readers require labels to be in their optical line-of-sight, something that is not required of RFID readers. This makes reading RFID barcodes much less time-consuming, as the scanners do not have to be individually positioned to scan each label in turn; rather an RFID reader can read tens of RFID tags in its scanning area simultaneously, speeding up the process considerably.

• Barcode labels can only be read at a limited distance, typically no more than 15 ft. In contrast, RFID scanners can read tags at up to 300 ft.

• It is impossible to alter the information in a barcode label once it is printed out. However, the RFID reader can communicate with RFID tags and alter the information in each rewritable tag. In addition, an RFID tag can store much more information than a barcode.

• Barcodes can be replicated or counterfeited with ease, while RFID tags are much more secure due to their greater complexity.

Although this comparison primarily focuses on the advantages of RFID over barcodes, the use of both technologies is not mutually exclusive. It is not expected that one will simply replace the other, but rather both may work in tandem in different marketing areas. In some respects, barcodes have advantages over RFID. For example, compared with RFID, barcode technology is easier to use and more affordable.

1.4 RFID technology

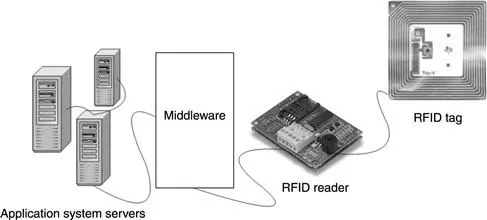

To fully utilize RFID technology in apparel supply chain operations, practitioners must understand the fundamentals of RFID technology clearly. To this end, the following section will outline the basics in order that the potential benefits of the technology may be fully understood. An RFID system usually consists of the three components shown in Fig. 1.1, which include:

1. RFID tags;

2. RFID readers;

3. middleware.

1.1 Architecture of an RFID system.

The RFID tag is attached to the item that is to be identified or tracked within the supply chain by the RFID system. The RFID reader provides multiple functions such as:

• powering and identifying RFID tags;

• reading (writing) data from (TO) tags; and

• communicating with the middleware.

The middleware can receive data from the RFID reader, and enter it into a database, as well as provide access to it. The communication mechanism between tag and reader is essential ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Textiles

- 1. The role of radio frequency identification (RFID) technologies in the textiles and fashion supply chain: an overview

- 2. The role of radio frequency identification (RFID) technologies in improving distribution and retail operations in the fashion supply chain

- 3. The role of radio frequency identification (RFID) technologies in improving process management and product tracking in the textiles and fashion supply chain

- 4. The role of radio frequency identification (RFID) technologies in improving garment manufacturing operations

- 5. The role of radio frequency identification (RFID) technologies in improving garment assembly line operations

- 6. Improving order allocation in fashion supply chains using radio frequency identification (RFID) technologies

- 7. Intelligent apparel product cross-selling using radio frequency identification (RFID) technology for fashion retailing

- 8. Measuring the impact of radio frequency identification (RFID) technologies in improving the efficiency of the textile supply chain

- 9. Modeling the effectiveness of radio frequency identification (RFID) technologies in improving sales performance in fashion retail outlets

- Index