- 438 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Once thought of as niche technology, operators today are utilizing more opportunities with casing and liners as formations and environments grow in difficulty, especially with the unconventional oil and gas boom. Casing and liners for Drilling and Completions, 2nd Edition provides the engineer and well designer with up-to-date information on critical properties, mechanics, design basics and newest applications for today's type of well. Renovated and simplified to cover operational considerations, pressure loads, and selection steps, this handbook gives you the knowledge to execute the essential and fundamental features of casing and liners. Bonus features include:

- Additional glossary added to explain oil field terminology

- New appendix on useful every day formulas such as axial stress, shear stress in tubes and principal stress components

- Listing section of acronyms, notations, symbols and constants for quick reference

- Concise step-by-step basic casing design procedure with examples

- Thorough coverage and tips on important field practice for installation topics

- Advanced methods for critical and horizontal well casing design including hydraulic fracturing

- Exhaustive appendices on foundational topics: units & nomenclature, solid mechanics, hydrostatics, borehole environment & rock mechanics, and a summary of useful formulas

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Casing and Liners for Drilling and Completion by Ted G. Byrom in PDF and/or ePUB format, as well as other popular books in Technologie et ingénierie & Ingénierie de la chimie et de la biochimie. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction to casing design

1.1 Introduction

In this textbook, we will explore the fundamentals and practices of basic casing design with some introduction to more advanced ideas and techniques. We will use a simple process that involves manual calculations and graphical plots. This is the historical method of learning casing design and will instill a depth of understanding. For the vast majority of casing strings run in the world this is still the method employed. Those engineers already well founded in the process may use more advanced techniques and specific software. While there is some excellent software on the market that does casing design, one cannot really learn the process using software. This is not by any means a harangue about casing design software; some of it is excellent and quite sophisticated especially compared to the crude first attempts that hit the market. But the unwelcome fact is that many who are using it are overwhelmed by multipage, detailed printouts, half of which they do not even pretend to understand. And truth be told, many of the “support” personnel experience the same problem. Information is not knowledge if you do not understand it.

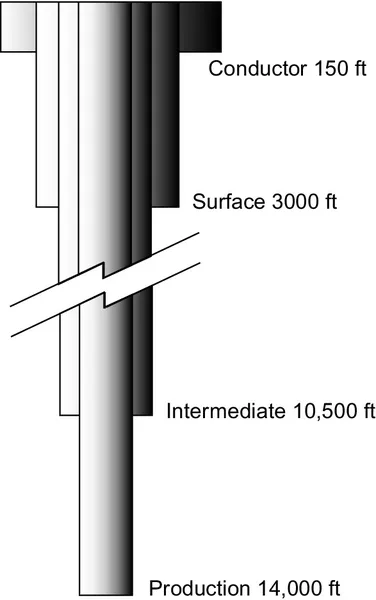

Figure 1.1 Casing string design for a typical well.

1.2 Design basics

Casing design is a bit different from most structural design processes in engineering because the “structure” being designed is a single tubular monolith of given outside diameter primarily supported from the top end. There is nothing to actually “design” in the conventional sense of structural engineering. Geometrically speaking, our structure is already designed. The available tubular sizes and strengths are standardized, so the design process maybe thought of as a two-step process:

1. Calculate the anticipated loads.

2. Selecting from the available standard tubes those with adequate strength to safely sustain those loads.

As simple as that may sound, casing design is still not a linear process. It is not a matter of calculating the anticipated loads and then selecting the casing. The selected casing itself is part of the load. Hence, the process must be iterated to account for that fact. Still, it is quite an easy process in the vast majority of cases.

The basic design/selection sequence in its iterative form might be listed in steps:

1. Determine depths and sizes of casing.

2. Determine pressure loads.

3. Apply design factors and make preliminary selection.

4. Determine axial loads and apply design factors.

5. Adjust preliminary selection for axial design loads.

6. Adjust for combined tension/collapse loading.

Some might not consider Step 1 a part of casing design, and technically that is true. That step might be done by someone other than the casing designer and not in conjunction with the actual design process. However, we are going to include it in our treatment because it is essential for us to understand how it is done and how the results affect our design process.

The actual design process starts with Step 2, where we calculate the pressure loads for various scenarios using basic hydrostatics. We do this for all the strings in the well.

In Step 3 we select the worst case pressure loading from the previous step and apply a design factor which gives us a margin to account for uncertainty in the loads and pipe strengths. The results of that are design pressure-load plots for each string of casing in the well. From these plots, we make preliminary selections of casing, which will safely sustain those design loads.

Because the axial load (weight) of the string is a function of the casing itself, we must then calculate it from the preliminary pressure-load selection. We then apply a design factor to the axial load and check to see if our preliminary selection has sufficient axial strength. If it does, Step 4 is complete and we skip Step 5. If it does not, then in Step 5, we must modify the preliminary selection so that it also satisfies the axial design load. When we modify the preliminary selection, we must recalculate the axial load for the modified string and apply our axial design factor again. We must also check to ascertain that the modified string still meets our pressure-load design requirements. So in this step, the process becomes iterative. It is not difficult though, because in the manual process, it is easy to visually see the values and minimize the iterations. Seldom are more than two iterations required.

Finally, in Step 6, we check for the effects of combined axial tension and collapse loading, often referred to as biaxial loading. This is a critical step even in basic casing design, because tension in a string reduces the collapse resistance of the casing. This step too may require several iterations because any change or adjustment in the casing selection always requires that all the loads be rechecked.

For your early reference, Step 1 is covered in Chapter 2, Step 2 in Chapter 3, and Steps 3-6 in Chapter 4. Chapter 5 covers the casing installation process, and the remainder of the chapters covers more advanced topics.

1.3 Conventions used here

There is in the petroleum literature a virtual plethora of odd terminology, incoherent physical units, mathematical inconsistencies, and so forth. I have tried to adhere to several principles in this book:

• A readable text

• A progressive sequence for learning and self education

• Sufficient background material in appendices

• Adherence to ISO mathematics [1] and mechanics [2] standards

...Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Acknowledgments

- Preface

- Preface to the First Edition

- Acronyms

- 1. Introduction to casing design

- 2. Casing depth and size determination

- 3. Pressure load determination

- 4. Design loads and casing selection

- 5. Installing casing

- 6. Casing performance

- 7. Casing in directional and horizontal wells

- Appendix A: Notation, symbols, and constants

- Appendix B: Units and material properties

- Appendix C: Basic mechanics

- Appendix D: Basic hydrostatics

- Appendix E: Borehole environment

- Appendix F: Summary of useful formulas

- Glossary

- References

- Index