eBook - ePub

Handbook of Waste Management and Co-Product Recovery in Food Processing

- 680 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Handbook of Waste Management and Co-Product Recovery in Food Processing

About this book

…an ideal information source for those involved in managing waste and recovering waste for use in products to produce revenue…(Food Science and Technology - review of Volume 1)This is a most welcome addition to the literature, likely to be essential study material for both technologists and process engineers.(The Chemical Engineer - review of Volume 1)Food processors are under pressure, both from consumers and legislation, to reduce the amount of waste they produce and to consume water and energy more efficiently. Handbook of waste management and co-product recovery in food processing provides essential information about the major issues and technologies involved in waste co-product valorisation, methods to reduce water and energy consumption, waste reduction in particular food industry sectors and end waste management.Opening chapters in Part one of Volume 2 cover economic and legislative drivers for waste management and co-product recovery. Part two discusses life cycle analysis and closed-loop production systems to minimise environmental impacts in food production. It also includes chapters on water and energy use as well as sustainable packaging. Part three reviews methods for exploiting co-products as food and feed ingredients, whilst the final part of the book discusses techniques for non-food exploitation of co-products from food processing.

- Provides essential information about the major issues and technologies involved in waste product valorisation

- Examines methods to reduce water and energy consumption in partciular food industry sectors

- Discusses the economic and legislative drivers for waste management and co-product recovery

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Handbook of Waste Management and Co-Product Recovery in Food Processing by Keith W. Waldron in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Environmental Management. We have over one million books available in our catalogue for you to explore.

Information

Part I

Economic and legislative drivers for waste management and co-product recovery

1

Sustainable value stream mapping in the food industry

A. Norton Imperial College London, UK

A. Fearne University of Kent, UK

Abstract

In this chapter, the principles behind sustainable value stream mapping or value chain analysis (SVCM) and how the technique can be applied are explained, placing particular emphasis on the importance of relationships and information flows between food retailers and food manufacturers. In any industry, waste occurs as both physical by-products and inefficient resource usage. The identification of opportunities for waste reduction requires an analysis of current activities and the waste arising from them. Value stream mapping (VSM) is a diagnostic technique that originated in lean manufacturing for the purpose of eliminating wasteful activities and reducing production lead time. SVCM is a recently developed method that incorporates the VSM approach, to include a suite of environmental parameters in addition to operational measures in order to evaluate the value stream of a product. Case study evidence indicates that order volatility and forecast inaccuracy make it difficult for manufacturers to estimate material requirements and to plan production, thus reducing efficiency and encouraging over-production to ensure availability, factors that increase both physical and operational wastes.

Key words

waste management

value chain analysis

value stream mapping

sustainability

1.1 Background

Since the adoption of Agenda 21 at the Rio Conference on Environment and Development in 1992, there has been recognition of the need to counter the adverse environmental effects of unsustainable patterns of consumption and production in industrialised countries. It was proposed within Agenda 21 that changing these patterns requires ‘… a multipronged strategy focusing on demand, meeting the basic needs of the poor, and reducing wastage and the use of finite resources in the production process’ (UN, 2004). Within the UK government’s Sustainable Development strategy, the proposition is expanded by the view that ‘much current consumption, and business models based on it, remain unsustainable in the longer term under present technologies and supply patterns’ and that there is a need for ‘process re-design, lean manufacturing and ways to use waste from one business as a resource for another’, using an approach that promotes ‘cleaner, more efficient production processes, which strengthen competitiveness’ (Anon., 2005). Thus, the UK government emphasises the need for greater efficiency and competitiveness in addition to environmental performance improvements.

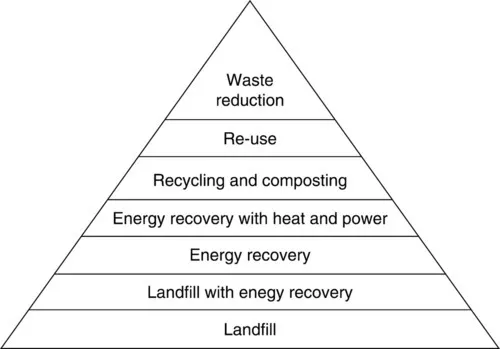

Within all industries, physical wastes and wasted resources occur at every stage in the supply chain. Once solid wastes have been generated, they require appropriate management so as to minimise the environmental impacts and risks to human health. However, all waste management methods have certain drawbacks: inefficiency owing to energy losses or additional energy usage; risks of emissions to environmental media; and, not least, the compounded wastes and wasted resources within the discarded materials from earlier stages in the supply chain. Therefore waste reduction is environmentally preferable to waste management, as the waste hierarchy illustrates (Fig. 1.1). Undoubtedly some wastes are unavoidable, for example, a certain fraction of raw materials, and these should be managed using the best practicable environmental option, an approach well established in EU and UK legislation. However, the economic benefits to be derived from preventing avoidable waste make this a highly worthwhile objective: businesses benefit from reduced costs for materials, resources and waste disposal; and consumers benefit from improved value because the price paid does not incorporate the costs of waste incurred throughout the supply chain. Given the undeniable benefits of waste reduction, the question arises as to how it should be achieved within manufacturing industries. How might the avoidable wastes be identified and eliminated?

Fig. 1.1 The waste hierarchy. (Source: Anon., 2002a)

1.2 The lean paradigm

Whilst working for the Japanese car manufacturer, Toyota, Taiichi Ohno formulated the ideas underlying what is now known as lean manufacturing. His primary aim was to reduce the time between the receipt of an order and the receipt of payment for its delivery by eliminating the nonvalue-adding wastes that he called ‘muda’, frequently called the Seven Wastes (Ohno, 1988). The Seven Wastes are:

1 waiting, by operators and machines;

2 transportation of materials;

3 unnecessary or overcomplicated processes;

4 excess stock or materials (inventory);

5 excess movement by operators;

6 defective products;

7 overproduction.

A lack of awareness of the Seven Wastes within the production chain results in low productivity, poor quality and increased costs. Ohno (1988) viewed overproduction as ‘our worst enemy – because it helps hide other wastes’. In other words, the six other wastes are compounded within overproduction.

Ohno’s ideas for reducing ‘muda’ formed the basis for lean thinking, which can be applied to the provision of any good or service (Womack and Jones, 2003). Womack and Jones (2003) propose that the Seven Wastes can be eliminated by minimising the activities that absorb resources but create no value, and aiming to provide the end-consumer with what he wants when (and only when) he wants it. Lean thinking has five basic principles (Womack and Jones, 2003):

1 Specify value: delivering value is fundamental to lean thinking. Only the end-consumer can define value, and it can only be expressed in reference to a specific product that meets the consumer’s needs at a specific price and at a specific time.

2 Identify the value stream: the value stream comprises all the activities necessary for the creation of a specific product, from the procurement of raw materials up to the point of sale to the end-consumer. Any value stream typically has three types of activity: those that create value; those that create no value but are essential; and those that create no value and are avoid...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Contributor contact details

- Preface

- Part I: Economic and legislative drivers for waste management and co-product recovery

- Part II: Environmental systems analysis and closed-loop factories

- Part III: Exploitation of co-products as food and feed ingredients

- Part IV: Non-food exploitation of wastes and co-products