eBook - ePub

Surface Production Operations: Vol 2: Design of Gas-Handling Systems and Facilities

- 672 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Surface Production Operations: Vol 2: Design of Gas-Handling Systems and Facilities

About this book

Updated and better than ever, Design of Gas-Handling Systems and Facilities, 3rd Edition includes greatly expanded chapters on gas-liquid separation, gas sweetening, gas liquefaction, and gas dehydration —information necessary and critical to production and process engineers and designers. Natural gas is at the forefront of today's energy needs, and this book walks you through the equipment and processes used in gas-handling operations, including conditioning and processing, to help you effectively design and manage your gas production facility. Taking a logical approach from theory into practical application, Design of Gas-Handling Systems and Facilities, 3rd Edition contains many supporting equations as well as detailed tables and charts to facilite process design. Based on real-world case studies and experience, this must-have training guide is a reference that no natural gas practitioner and engineer should be without.

- Packed with charts, tables, and diagrams

- Features the prerequisite ASME and API codes

- Updated chapters on gas-liquid separation, gas sweetening, gas liquefaction and gas dehydration

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Surface Production Operations: Vol 2: Design of Gas-Handling Systems and Facilities by Maurice Stewart in PDF and/or ePUB format, as well as other popular books in Architecture & Architecture General. We have over one million books available in our catalogue for you to explore.

Information

Chapter One

Overview of Gas-Handling, Conditioning, and Processing Facilities

Abstract

This chapter introduces the methods and equipment used in handling, conditioning, and processing natural gas for sale. It begins by presenting the objectives of gas-handling, conditioning, and processing facilities. It then summarizes the contents of each chapter. At the end of the chapter, the main processes of a gas field facility are presented in a process block diagram, and each component in the diagram is explained in detail. The chapter closes by presenting a sample gas field. The described field provides the basis for the many example problems addressed in the subsequent chapters.

Keywords

heating

choke

separation

cooling

condensate stabilization

compression

gas treating

gas dehydration

gas processing

dew point

acid gas

hydrates

flowing tubing pressure

shut-in tubing pressure

Volume 1 of the Surface Production Operations series focuses on the processes and equipment involved with oil-handling facilities. Volume 2 focuses on the processes and equipment involved with gas-handling, conditioning, and processing of natural gas for sale. Volume 3 focuses on plant (facilities) piping and pipeline systems. It also covers relief, vent and flare systems. Volume 4 focuses of rotating equipment, specifically pumps, compressors and drivers. Volume 5 focuses on instrumentation, process control and safety systems. The objective of gas-handling, conditioning, and processing facilities is to separate natural gas, condensate, or oil and water from a gas-producing well and condition these fluids for sale or disposal.

Chapter 2 discusses basic principles and fluid properties. Heat transfer theory and heat exchanger equipment are discussed in Chapters 3 and 4. Hydrate prediction and prevention are discussed in Chapter 5. Condensate stabilization, the process of flashing the lighter hydrocarbons to gas and maximizing the recovery of natural gas liquids (NGLs), is the topic of Chapter 6. The subject of Chapter 7is methods of gas dehydration, and specific comments on maintenance, care, and troubleshooting of glycol dehydration systems are the topics of Chapter 8. Gas sweetening, the removal of acid gas compounds (primarily carbon dioxide and hydrogen sulfide) from natural gas, is discussed in Chapter 10. Gas processing to extract natural gas components, primarily ethane, propane, butane and heavier NGLs, from a natural gas stream is discussed in Chapter 10. Treating the condensate, or oil and water, after the initial separation from the natural gas is covered in Volume 1.

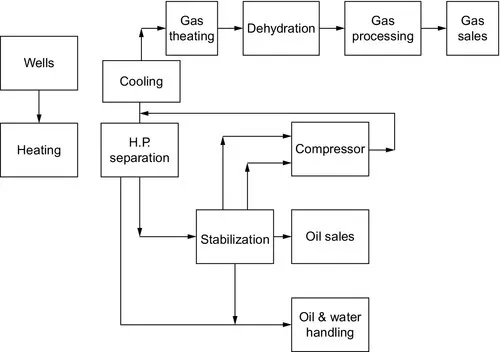

Figure 1.1 is a simple block diagram of a production facility that is primarily designed to handle gas wells. Each of the main blocks is described herein.

Figure 1.1 Gas field facility block diagram.

1.1 Heating

The well flow stream may require heating prior to initial separation. Gas wells are often high pressure (HP) with shut-in tubing pressure of 5000-15,000 psig and flowing-tubing pressure (FTP) often exceeding 3000 psig. This pressure must be reduced to the appropriate operating pressure of the surface facilities and pipelines.

A choke is installed to control the flow. When the flow stream is choked, gas expands, temperature decreases, and liquids condense. If the temperature gets low enough, hydrates will form. Hydrates are crystalline solids made up of hydrocarbon and water molecules and form in the presence of hydrocarbon gas and liquid water at temperatures significantly higher than the freezing point of water. Hydrates can plug the flow-line, choke, and downstream equipment and reduce the capacity of vessels and pipelines. Therefore, flow from high-pressure gas wells may have to be heated to a temperature above the hydrate formation temperature before or immediately after the pressure drop from FTP to separator pressure, which occurs at the choke. Refer to Chapter 5 on Hydrate Prediction and Prevention, of this volume, for a more complete discussion of hydrates.

1.2 Separation

The HP separator provides a location for liquid to settle out from the gas. Normally, if the FTP is high enough, the separator pressure is set higher than the sales gas pipeline pressure so that the gas can go through the required cooling, treating, dehydration, and gas processing equipment, experience some pressure drop, and arrive at the required departing pipeline pressure.

Typically, in a gas facility, there is an initial separation at a HP, enabling reservoir energy to move the gas through the process to sales. It is very rare that the flowing-tubing pressure of a gas well, at least initially, is less than the gas sales pressure. With time, the flowing-tubing pressure may decline and compression may be needed prior to further handling of the gas. The initial separation is normally three-phase, as the separator size is dictated by gas capacity. That is, the separator will typically be large enough to provide sufficient liquid retention time for three-phase separation if it is to be large enough to provide sufficient gas capacity. Selection and sizing of separators are described in Volume 1.

1.3 Cooling

It is also possible that cooling may be necessary. If the flowing gas temperature is high, the temperature downstream of the choke may be high enough so that adding heat upstream of the HP separator is not required. If a substantial amount of gas and liquid is being produced, or if the flowing tubing temperature is very hot (e.g., from a deep high-pressure, high-temperature gas well), the gas temperature leaving the HP separator could be above the temperature that can easily be handled by the downstream processes. There is a maximum practical temperature for inlet streams to acid-gas treating and dehydration equipment. Hot gas leaving the HP separator carries more water vapor and increases the load on the downstream dehydration systems, which results in a much more expensive system than if the gas were cooled first. In addition, hot inlet gas could severely limit the ratio of discharge pressure to suction pressure that could be obtained from a downstream compressor. Thus, the gas may have to be cooled prior to compression, treating, and/or dehydration.

The cooler is typically an aerial cooler or a shell-and-tube exchanger that uses seawater or a contained cooling-water loop, which is cooled by seawater or some other water source. Ideal gas temperatures are in the 80°-110 °F (27-43 °C) range.

In some fields, it may be necessary to provide heat during the early life of the wells when flowing-tubing pressures are high and there is a high-temperature drop across the choke. Later on, if the wells produce more liquid and the flowing-tubing pressure decreases, it may be necessary to ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- Acknowledgments

- Chapter One: Overview of Gas-Handling, Conditioning, and Processing Facilities

- Chapter Two: Basic Principles

- Chapter Three: Heat Transfer Theory

- Chapter Four: Heat Exchanger Configurations

- Chapter Five: Hydrate Prediction and Prevention

- Chapter Six: Condensate Stabilization

- Chapter Seven: Dehydration

- Chapter Eight: Glycol Maintenance, Care, and Troubleshooting

- Chapter Nine: Gas Sweetening

- Chapter Ten: Gas Processing

- Chapter Eleven: Safety Systems

- Appendix A: Case Study: Membrane/Amine Hybrid Grissik Gas Plant [1–3], Sumatra, Indonesia

- Appendix B: Case Study: The Judge Digby Gas Plant Hikes Production with Quick Solvent Change-Out [1]

- Index