- 544 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Non-crimp fabric (NCF) composites are reinforced with mats of straight (non-crimped) fibres, giving them such advantages as strength, ease of handling and low manufacturing costs. Non-crimp fabric composites provides a comprehensive review of the use of NCF composites, their manufacture and applications in engineering.Part one covers the manufacture of non-crimp fabrics, including also topics such as structural stitching and automated defect analysis. Part two goes on to discuss the manufacture of non-crimp fabric composites, with chapters covering such topics as deformability and permeability of NCF. Part three focuses on the properties of NCF composites, with chapters on stiffness and strength, damage progression and fatigue. Finally, part four covers the applications of NCF composites, including chapters on the aerospace and automotive industries as well as wind turbines and helicopter applications. The book concludes with a discussion of cost analysis of NCF composites in engineering applications.With its distinguished editor and international team of expert contributors, Non-crimp fabric composites is an essential reference for composite manufacturers and structural and mechanical engineers in industries using NCF composites, as well as academics with a research interest in the field.

- Provides a comprehensive review of the use of NCF composites, their manufacture and applications in engineering

- Reviews the manufacture of non-crimp fabrics, including also topics such as structural stitching and automated defect analysis

- Examines the properties of NCF composites considering stiffness and strength, damage progression and fatigue

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Non-Crimp Fabric Composites by Stepan V Lomov in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

Part I

Manufacturing of non-crimp fabrics

1

Production of non-crimp fabrics for composites

A. Schnabel and T. Gries, Institut für Textiltechnik (ITA) of RWTH AachenUniversity, Germany

Abstract:

For the manufacturing of non-crimp fabrics there is a wide range of production technologies. The focus in this chapter is on the production of warp-knitted non-crimp fabrics. The production process of coursewise and non-coursewise biaxial and multiaxial warp-knitted NCF is described in detail and the production of non-crimp fabrics by means of weft knitting with weft insertion and specially adapted weaving processes is explained. Other processes are shown to produce non-crimp fabrics made of tapes and threads by means of resins or adhesives. The different technologies are compared and evaluated. An outlook on actual and future research topics and developments concludes this chapter.

Key words:

production of non-crimp fabric (NCF)

warp-knitted NCF

weft-knitted NCF

non-crimp woven fabric

fixation by adhesion

1.1 Introduction

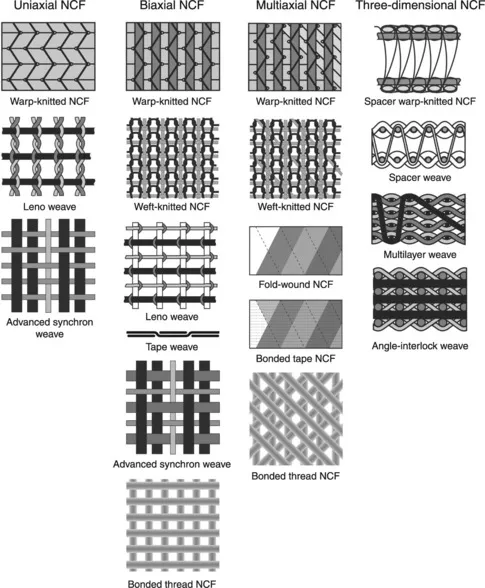

The chapter ‘Production of non-crimp fabrics, for composites’ comprises a short introduction to non-crimp fabric (NCF), an overview of production technologies and the produced fabrics, a comparison of production technologies, current trends and an outlook on the future. Non-crimp fabrics are defined as drawn parallel oriented layers of reinforcing threads or tows, which are positioned by means of an additional fixation material. Figure 1.1 gives an overview of different NCF structures.

1.1 Overview of different non-crimp fabrics (ITA).

In technical literature, there is a wide range of terms for the production technologies for different kinds of fabrics. Furthermore, no uniform designation of thread systems is used. Therefore, at the beginning of each section, the terms used are introduced and, for clarity, throughout the chapter the terms ‘thread’ and ‘fibre’ will be used for reinforcement systems and ‘yarn’ for auxiliary systems. The definition of Roye et al. (2005), is used for the expressions two-dimensional (2D) textile and three-dimensional (3D) textile.

• A textile is defined as a 2D structure if it does not extend in more than two directions, neither in yarn architecture nor in textile architecture.

• A textile is defined as a 3D structure if its yarn architecture and/or its textile architecture extends in three directions, regardless of whether it is made in one step or in a multiple-step process.

A cornerstone for the production of NCF was set in 1949 with patent number DD000000008194A, granted to Heinrich Mauersberger. The patent describes a novel textile material and the associated production method. The basic idea is that chain-stitch seams are used for the production of textile fabrics by interlinking loose filling threads or drawn parallel weft threads. Intersecting weft threads are routed with a guide rail and connected with chain-stitch seams. Threads that are fed in process direction to the stitching unit can be fixed via a ‘zig-zag’ chain stitch. The position of the needle puncture should be between two weft threads (Mauersberger, 1954).

NCF can also be produced with coursewise warp-knitting technology, weft-knitting technology and specially adapted weaving processes. Besides the above-mentioned methods, incoherent reinforcing fibre layers are joined and positioned by being pre-impregnated with resin or by fixation with adhesives. Adhesives for the joining of non-crimp fabrics are used in the form of fluid, powder, granulate or non-woven hotmelt.

1.2 Warp-knitted non-crimp fabric (NCF)

Knitting processes with loop formation in production direction are called warp-knitted fabrics. The compound needles are assembled on a continuous needle bar and moved together during the loop formation. Due to the production process, warp-knitted fabrics are created with several yarn systems (Anon., 1969). In warp-knitted NCFs the loop formation is used to bind reinforcing layers together. The machine technology is very productive compared to other technologies. Warp-knitted NCFs are very flexible in respect to layer setup and fibre orientation, but they are limited to a constant width and area weight.

There is coursewise and non-coursewise fixation of the reinforcing threads. In a machine with coursewise weft insertion, every warp and weft thread is bound with a single knitting loop. Compared to other technologies, the threads remain undisturbed. The stitch length can be defined in the machine settings. The technology for coursewise biaxial and multiaxial NCF is called warp-knitting. In machines with a non-coursewise weft insertion, the stitch length is independent to the position of the thread. Therefore, threads can be damaged or deflected. There exist non-coursewise biaxial and multiaxial NCF. Non-coursewise multiaxial NCFs are called warp-knitted multiaxial layers (Verwirkte multiaxiale Gelege; WIMAG) or stitch-bonded fabrics (Nähgewirkte variable Gelege; NVG). These phrases were coined in the Federal Republic of Germany and in the former German Democratic Republic, respectively. The term ‘stitch-bonding’ is more appropriate to describe non-coursewise weft insertion technology. Nevertheless, in the following, the more common term ‘warp-knitting’ will be used for non-coursewise biaxial and multiaxial NCF (Weber and Weber, 2004; Wulfhorst, 1998). Table 1.1 shows the important properties of coursewise and non-coursewise fabrics and the relating production technologies.

Table 1.1

Characteristics of coursewise and non-coursewise non-crimp fabric and the relating production technologies

| Coursewise weft insertion | Non-coursewise weft insertion | |

| Fibre damage | – | + |

| Dislocation of the reinforcing threads | – | + |

| Variability of the stitch length | + | + |

| Complexity of the machine technology | + | – |

+ Higher/- Lower

1.2.1 Biaxial warp-knitted NCF

Fabric set-up

Biaxial warp-knitted NCFs are made out of at least three thread systems.

• Pillar threads (0°).

• Weft threads (90°).

• Warp-knitting yarn...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Introduction

- Part I: Manufacturing of non-crimp fabrics

- Part II: Manufacturing of non-crimp fabric composites

- Part III: Properties of non-crimp fabric composites

- Part IV: Applications of non-crimp fabric composites

- Index