- 660 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Handbook of Silicon Wafer Cleaning Technology

About this book

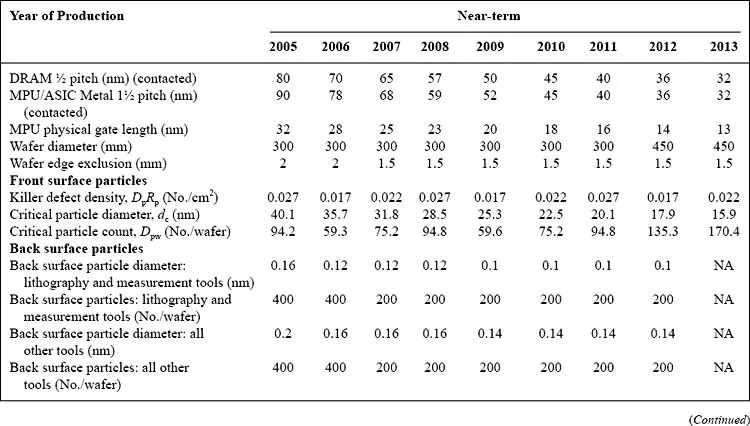

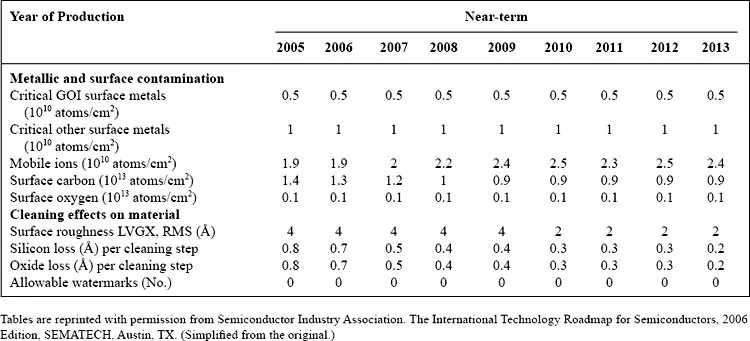

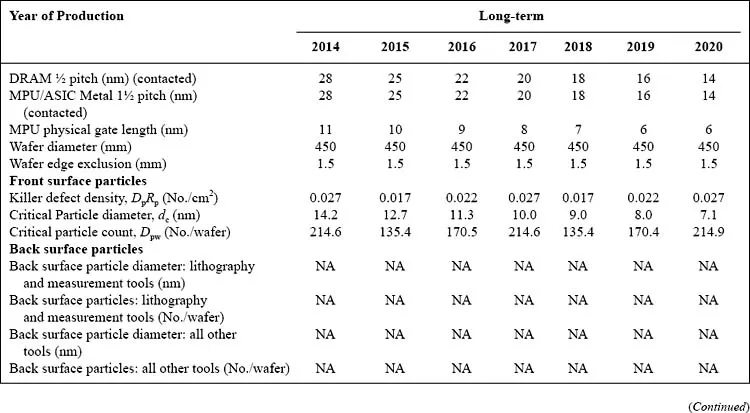

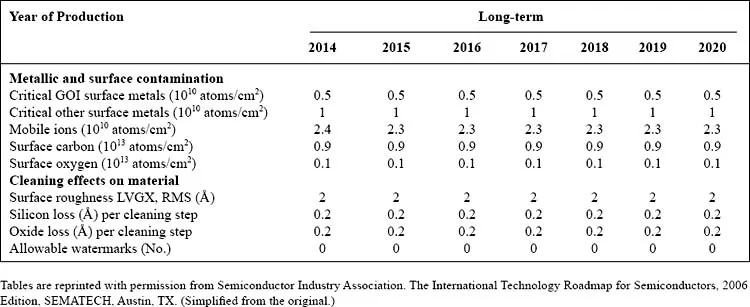

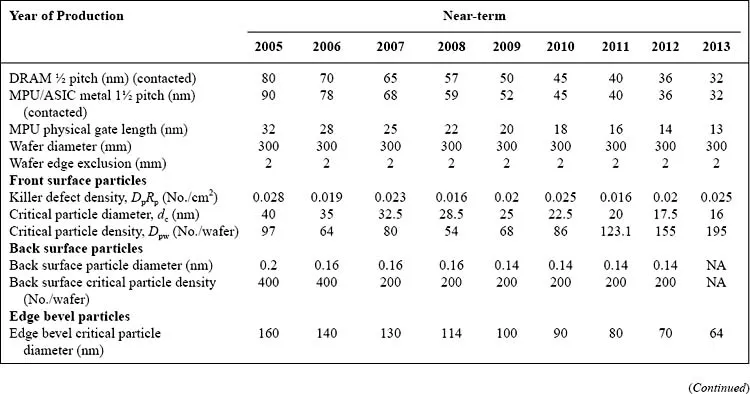

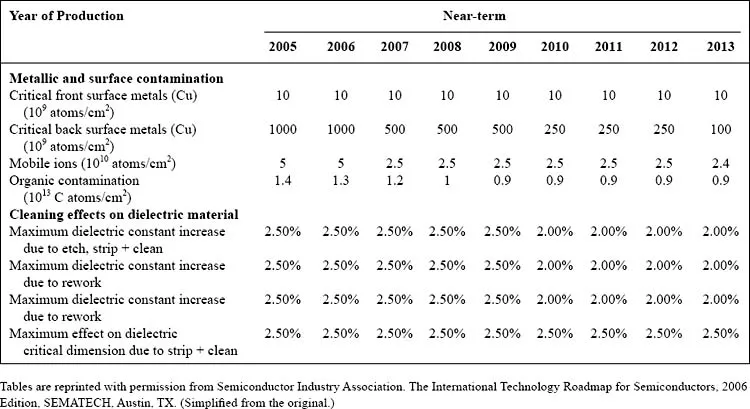

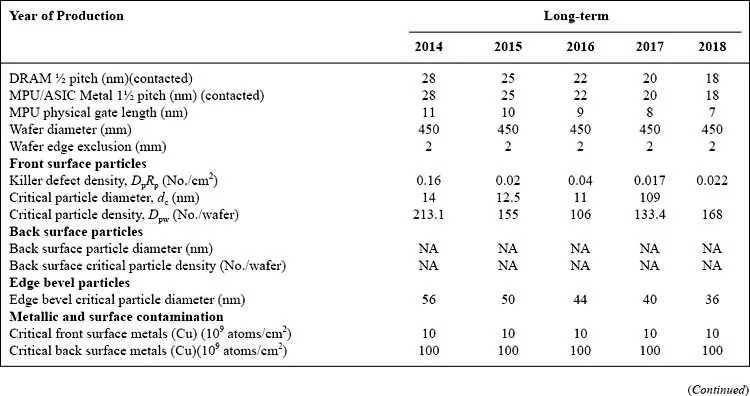

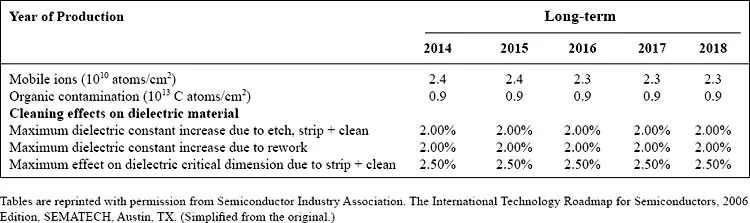

The second Edition of the Handbook of Silicon Wafer Cleaning Technology is intended to provide knowledge of wet, plasma, and other surface conditioning techniques used to manufacture integrated circuits. The integration of the clean processes into the device manufacturing flow will be presented with respect to other manufacturing steps such as thermal, implant, etching, and photolithography processes. The Handbook discusses both wet and plasma-based cleaning technologies that are used for removing contamination, particles, residue, and photoresist from wafer surfaces. Both the process and the equipment are covered. A review of the current cleaning technologies is included. Also, advanced cleaning technologies that are under investigation for next generation processing are covered; including supercritical fluid, laser, and cryoaerosol cleaning techniques. Additionally theoretical aspects of the cleaning technologies and how these processes affect the wafer is discussed such as device damage and surface roughening will be discussed. The analysis of the wafers surface is outlined. A discussion of the new materials and the changes required for the surface conditioning process used for manufacturing is also included.- Focused on silicon wafer cleaning techniques including wet, plasma, and other surface conditioning techniques used to manufacture integrated circuits- As this book covers the major technologies for removing contaminants, it is a reliable reference for anyone that manufactures integrated circuits, or supplies the semiconductor and microelectronics industries- Covers processes and equipment, as well as new materials and changes required for the surface conditioning process- Editors are two of the top names in the field and are both extensively published- Discusses next generation processing techniques including supercritical fluid, laser, and cryoaerosol

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1.1 Introduction

1.2 Importance of Clean and Conditioned Wafer Surfaces

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Foreword

- Preface to the Second Edition

- Preface to First Edition

- PART I: INTRODUCTION AND OVERVIEW

- PART II: WET CHEMICAL PROCESS

- PART III: DRY CLEANING PROCESSES

- PART IV: ANALYTICAL AND CONTROL ASPECTS

- PART V: DIRECTIONS FOR THE NEAR FUTURE

- Book Editors and Chapters Authors

- Index

- Materials Science and Process Technology Series