- 327 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Rotational Molding Technology

About this book

This book clarifies and quantifies many of the technical interactions in the process. It distinguishes itself from other books on the subject by being a seamless story of the advanced aspects of the rotational molding process. There are seven chapters within the book. The US market for rotational molding products was one billion pounds in the year 2000. The growth of the rotational molding industry has grown at 10 to 15% per year. With this growth has come an increasing need for details on the complex, technical aspects of the process.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

INTRODUCTION TO ROTATIONAL MOLDING

1.0 Introduction

Rotational molding, known also as rotomoldingor rotocasting, is a process for manufacturing hollow plastic products. For certain types of liquid vinyls, the term slush molding is also used. Although there is competition from blow molding, thermoforming, and injection molding for the manufacture of such products, rotational molding has particular advantages in terms of relatively low levels of residual stresses and inexpensive molds. Rotational molding also has few competitors for the production of large (> 2 m3) hollow objects in one piece. Rotational molding is best known for the manufacture of tanks but it can also be used to make complex medical products, toys, leisure craft, and highly aesthetic point-of-sale products.

It is difficult to get precise figures for the size of the rotational molding market due to the large number of small companies in the sector. In 1995, the North American market was estimated to be about 800 million pounds (364 ktons) with a value of US$1250 million.1 The corresponding 1995 figure for Europe was a consumption of 101 ktons,2 and this had risen to 173 ktons by 1998.3 In 1997, the North American market had a value of about US$1650 million and for most of the 1990s, the U.S. market grew at 10% to 15% per year, spurred on primarily by outdoor products such as chemical tanks, children’s play furniture, kayaks, canoes, and mailboxes.4 In the latter part of the 1990s the North American market growth slowed to single figures. Independent analysts5, 6 saw this as a temporary dip and explained it in terms of a readjustment of market sectors and increasing competition from other sectors.

Currently, the rotational molding industry is in an exciting stage in its development. The past decade has seen important technical advances, and new types of machines, molds, and materials are becoming available. The industry has attracted attention from many of the major suppliers and this has resulted in significant investment. Important new market sectors are opening up as rotational molders are able to deliver high quality parts at competitive prices. More universities than ever are taking an interest in the process, and technical forums all over the world provide an opportunity for rotational molding to take its place alongside the other major manufacturing methods for plastics.

1.1 The Process

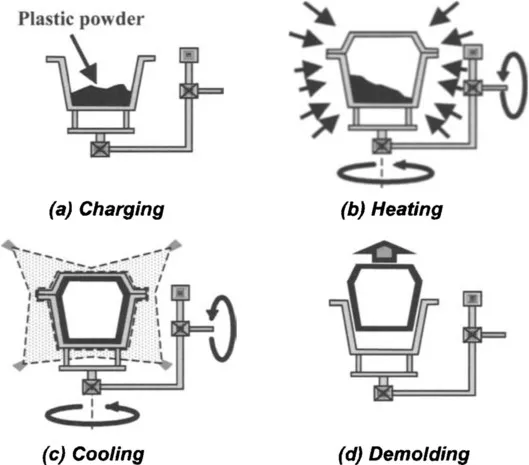

The principle of rotational molding of plastics is simple. Basically the process consists of introducing a known amount of plastic in powder, granular, or viscous liquid form into a hollow, shell-like mold.7–9 The mold is rotated and/ or rocked about two principal axes at relatively low speeds as it is heated so that the plastic enclosed in the mold adheres to, and forms a monolithic layer against, the mold surface. The mold rotation continues during the cooling phase so that the plastic retains its desired shape as it solidifies. When the plastic is sufficiently rigid, the cooling and mold rotation is stopped to allow the removal of the plastic product from the mold. At this stage, the cyclic process may be repeated. The basic steps of (a) mold charging, (b) mold heating, (c) mold cooling, and (d) part ejection are shown in Figure 1.1.

Figure 1.1 Principle of rotational molding, courtesy of The Queen’s University, Belfast

Nearly all commercial products manufactured in this way are made from thermoplastics, although thermosetting materials can also be used. The majority of thermoplastics processed by rotational molding are semicrystalline, and the polyolefins dominate the market worldwide. The different types of products that can be manufactured by rotational molding are summarized in Table1.1 The process is distinguished from spin casting or centrifugal casting by its low rotational speeds, typically 4 – 20 revs/min. The primary competitors to rotational molding are structural blow molding and twin-sheet thermoforming.

Table 1.1

Typical Applications for Rotationally Molded Products

| Tanks | |

| Septic tanks | Chemical storage tanks |

| Oil tanks | Fuel tanks |

| Water treatment tanks | Shipping tanks |

| Automotive | |

| Door armrests | Instrument panels |

| Traffic signs/barriers | Ducting |

| Fuel tanks | Wheel arches |

| Containers | |

| Reusable shipping containers | Planters |

| IBCs | Airline containers |

| Drums/barrels | Refrigerated boxes |

| Toys and Leisure | |

| Playhouses | Outdoor furniture |

| Balls | Hobby horses |

| Ride-on toys | Doll heads and body parts |

| Materials Handling | |

| Pallets | Fish bins |

| Trash cans | Packaging |

| Carrying cases for paramedics | |

| Marine Industry | |

| Dock floats | Leisure craft/boats |

| Pool liners | Kayaks |

| Docking fenders | Life belts |

| Miscellaneous | |

| Manhole covers | Tool boxes |

| Housings for cleaning equipment | Dental chairs |

| Point-of-sale advertising | Agricultural/garden equipment |

As with most manufacturing methods for plastic products, rotational molding evolved from other technologies. A British patent issued to Peters in 1855 (before synthetic polymers were available) cites a rotational molding machine containing two-axis rotation through a pair of bevel gears. It refers to the use of a split mold having a vent pipe for gas escape, water for cooling the mold, and the use of a fluid or semifluid material in the mold to produce a hollow part. In the original patent application this was a cast white metal artillery shell. In Switzerland in the 1600s, the formation of hollow objects such as eggs quickly followed the development of chocolate from cocoa. The ceramic pottery process known today as “slip casting” is depicted in Egyptian and Grecian art, and probably predates history.

1.2 The Early Days

Rotational molding of polymers is said to have begun in the late 1930s with the development of highly plasticized liquid polyvinyl chloride, the thermoplastic competitor to latex rubber.9–14 In addition to the ubiquitous beach balls and squeezable toys, syringe bulbs, squeezable bottles and bladders and air-filled cushions were developed during World War II. Until polyethylene powders were produced in the late 1950s, most rigid articles were manufactured from cellulosics. The early equipment was usually very crude. Generally it consisted of a hollow metal mold rotating over an open flame. Sometimes a type of slush molding would be used. In this method, the mold would be completely filled with liquid or powde...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- About the Authors

- Chapter 1: INTRODUCTION TO ROTATIONAL MOLDING

- Chapter 2: ROTATIONAL MOLDING POLYMERS

- Chapter 3: GRINDING AND COLORING

- Chapter 4: ROTATIONAL MOLDING MACHINES

- Chapter 5: MOLD DESIGN

- Chapter 6: PROCESSING

- Chapter 7: MECHANICAL PART DESIGN

- Appendix A: Troubleshooting Guide for Rotational Molding

- Appendix B: Conversion Table

- Author Index

- Subject Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Rotational Molding Technology by R.J. Crawford,James L Throne in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.