Fluid leaks in hydraulic and lubricating systems are a commonplace occurrence in much mechanical equipment, and they are undesirable and embarrassing events fuelling increased cost of any manufacturing and equipment maintenance activity. Often fire hazards and accidents are direct consequences of such leakages. In many situations, in spite of anticipation of such hazards, leaks are overlooked and the leaking system is not attended to, since the operating engineers do not take the threat of accidents seriously. For years, leakage has received low level attention by corporate management at many industrial manufacturing plants. One reason is that leaks are often viewed as inevitable, and corrective actions such as repair and replacement are done only when convenient.

According to a recent report by John C Cox, Business Development Manager of Swagelok Company Solon Ohio [1], fluid leakage costs industry millions of dollars every year. For example, a few small leaks in a facility using air at 100 psig with an electric consumption cost of 6 cents/kwh can waste more than $22 000 annually. Delaying the replacement of a leaking steam trap worth $100, or not repairing it with proper sealing, could waste $50 per week. Since an average facility can typically have hundreds of steam traps throughout its operations, leaking traps may be squandering hundreds of thousands of dollars each year. In addition to wasted dollars, unattended leaks can result in downtime, affect product quality, pollute the environment and cause injury. System vibration, pulsation and thermal cycling are all common causes of chemical processing system leakage. It can be assumed that any type of fitting connection may leak, regardless of whether pipe or tube is used, especially when mechanical vibration is present. This ‘vibration fatigue’ is an unavoidable factor that can be aggravated by poor metallurgical consistency in the construction material, undue stress imposed on the connection from side load, other system design characteristics, or simply improper installation practices.

Seal Failures And Fluid Leak

The increasing speed of mechanical systems, warranted by the desire for increased productivity, leads to higher operating temperatures and reduced fluid viscosities. This, associated with higher pressures, causes an increasing tendency for fluids to leak. Such leakage in fuel systems that handle highly inflammable solvents cannot be overlooked as there is a high probability of fire hazards. It has become common practice to include a safe leakage route in the system design, to an escape or collection point in order to minimize the risk. However, this is a wasteful solution both in terms of cost and additional space needed for such a device. Unattended leaks result in downtime, affect product quality and pollute the atmosphere, in addition to wasting dollars.

If a seal leaks for no apparent reason, or shows cracks and blisters, it could be reacting with the fluid it is sealing. This problem is especially severe if the fluid has a molecular structure similar to that of the seal rubber. If this fluid interaction is the cause of seal failure, one has to see how to avoid the problem.

Blisters and internal cracks indicate that a seal is interacting with a fluid. Such failures, which are evident only upon close examination of the seal, are caused by fluid permeating into and expanding microscopic voids in the rubber.

Rubber seal materials are normally chosen on the basis of chemical compatibility with the fluid being transferred, but even if seal and fluid are chemically compatible, they can still interact physically, leading to leakage. Failure results from the fluid literally digging into the seal and bursting it from the inside. The reaction produces blisters or cracks in the seal that eventually provide a path for fluid leakage. This problem is especially acute at high temperatures and pressures, but it can show up even under less severe operating conditions. Work with seals for oil wells has provided insight on how to recognize failures caused by fluid/seal interaction. Fluids interact with seals because no seal material is 100% solid. Typically, molecular voids or air spaces make up about 3% of a seal's volume at its glass-transition temperature [2]. Under pressure, fluid diffuses into these voids and reaches an equilibrium state. Any change in equilibrium creates a positive internal pressure in the voids. If the pressure exceeds a critical level, the voids expand, forming a blister or rupture. Blistering is characteristic of highly elastic materials used to seal supersaturated gases, that have the following physical properties:

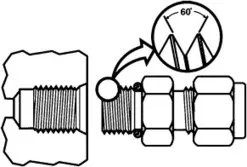

An example of leak prevention with a rubber seal in a thread fitting that is gaining popularity is the Society of Automotive Engineers’ (SAE) straight thread. The SAE straight threads are mechanical types, designed to only hold the fitting in place; they do not provide a seal. This is provided by a rubber inset, typically located at the base of the male thread (Figure 1.1). The rubber compresses against a flat surface near the entrance to the female port. This type of threaded seal offers the advantage that the maintenance, accessibility and replacement of the fitting is significantly easier for the installer.

In another interesting report, the principal author, S. Hunt of Dominion Engineering Inc., states the following in one of his chapters [4]:

Successful sealing involves containment of fluid within the system while excluding contaminants. For example, in a typical reciprocating sealing system, rubber materials are found to have dimensional variations due to manufacturing tolerances, loads and deformations in the cylinder under pressure. System pressure on the seal surface attempts to compress the seal axially. This compression forces the seal more tightly against its contacting metal surface. The resilience of rubber creates a tight sealing effect containing the fluid and excluding any contaminants.

The mechanical engineer who is familiar with metals looks to a rubber technologist whenever leakage in a fluid system is encountered. Leakages are encountered in a range of disciplines, such as fluid flow, lubrication, hydraulic system and piping technologies. The leak needs to be rectified for at least the life-time of the component where the seal is fitted. Mechanical engineers involved in many branches of industry are more familiar with metals rather than elastic rubbers. Often they turn to rubber technologists, since rubber is a unique and appropriate material for sealing fluid leaks unlike rigid metals. ‘What materials make a good seal?’ asks Professor Michael F. Ashby and he answers ‘Elastomers – everyone knows that’ [5]. The terms elastomer and rubber are scientifically interchangeable, although the latter is used in some areas to refer only to natural rubber, which comes from the latex of hevea trees, as opposed to synthetic rubber, which is generally a petroleum oil by-product. Some standards use the term elastomer for cross-linked materials, but there is no general agreement on this. In the literature, the terms elastomer, polymers and rubbers are synonymous.

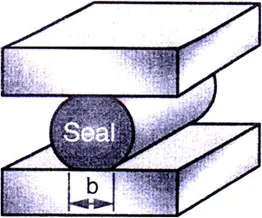

How can a rubber seal be explained simply? It can be visualized as a cylindrical item compressed between two flat surfaces as shown in Figure 1.2.

The seal must form the largest possible contact width ‘b’ and must not damage the contact surfaces. The seal itself must remain elastic so that it can be dynamic or static.

Although the author enumerates some application details of rubber seals, the primary focus of this book is on the characteristics of rubbers as seals. Their manufacturing procedures, the implications of their physical and chemical characteristics for sealing in fluid and hydraulic systems, how rubbers seal and prevent leaks, what properties are required for sealing function, and how they change before and after installation are also discussed. It is hoped that this will draw mechanical engineers closer to rubber technology.

The author has experience of working with mechanical, chemical, aviation and ship building engineers to solve their leakage problems, it is hoped, therefore, that this book will benefit those people, as well as scientists and technologists engaged in leakage prevention management. The author believes that this book might contribute its share in combating fluid leak threats. During his search, he found no book that dealt exclusively with rubber as industrial fluid seals was available in the literature, although valuable information related to the subject could be found in industry documents and research reports. These are cited where relevant, and detailed in the Reference Sections. A sound understanding of the complex factors involved in successful fluid sealing is essential for engineers who specify, design, operate and maintain machinery and mechanical equipment. Rubber seal specialists will show how an understanding of basic engineering factors can be used to practical advantage. Fluid sealing technology is based on principles as diverse as lubrication, friction, wear, properties of materials, mechanical design, fluid mechanics and heat transfer. All of these factors are to be considered and studied in depth in designing different types of rubber seals, seal materials and sealing applications.