Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification

- 1,088 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification

About this book

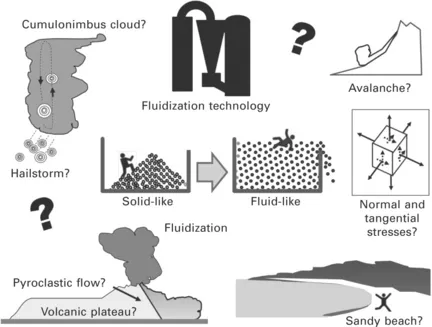

Fluidized bed (FB) combustion and gasification are advanced techniques for fuel flexible, high efficiency and low emission conversion. Fuels are combusted or gasified as a fluidized bed suspended by jets with sorbents that remove harmful emissions such as SOx. CO2 capture can also be incorporated. Fluidized bed technologies for near-zero emission combustion and gasification provides an overview of established FB technologies while also detailing recent developments in the field.Part one, an introductory section, reviews fluidization science and FB technologies and includes chapters on particle characterization and behaviour, properties of stationary and circulating fluidized beds, heat and mass transfer and attrition in FB combustion and gasification systems. Part two expands on this introduction to explore the fundamentals of FB combustion and gasification including the conversion of solid, liquid and gaseous fuels, pollutant emission and reactor design and scale up. Part three highlights recent advances in a variety of FB combustion and gasification technologies before part four moves on to focus on emerging CO2 capture technologies. Finally, part five explores other applications of FB technology including (FB) petroleum refining and chemical production.Fluidized bed technologies for near-zero emission combustion and gasification is a technical resource for power plant operators, industrial engineers working with fluidized bed combustion and gasification systems and researchers, scientists and academics in the field.- Examines the fundamentals of fluidized bed (FB) technologies, including the conversion of solid, liquid and gaseous fuels- Explores recent advances in a variety of technologies such as pressurized FB combustion, and the measurement, monitoring and control of FB combustion and gasification- Discusses emerging technologies and examines applications of FB in other processes

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Overview of fluidization science and fluidized bed technologies

Abstract:

1.1 Introduction

1.1.1 Fluidization in industry and its special features

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Energy

- Preface

- Part I: Introduction to fluidization science and technology

- Part II: Fundamentals of fluidized bed combustion and gasification

- Part III: Fluidized bed combustion and gasification technologies

- Part IV: Emerging CO2 capture technologies

- Part V: Other applications of fluidized bed technology

- Index