Membrane Contactors: Fundamentals, Applications and Potentialities

- 516 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Membrane Contactors: Fundamentals, Applications and Potentialities

About this book

Membrane Contactors: Fundamentals, Applications and Potentialities, Volume 11 covers new operations that could be efficiently used to improve the performance of a variety of industrial production cycles in applications ranging from biotechnology to agrofood. This book focuses on the basic "principles of work": required membrane materials and properties; major operating parameters; the importance of module configuration and design and; the performance of membrane contactors in specific processes. The authors' dynamic approach to this subject makes Membrane Contactors: Fundamentals, Applications and Potentialities, Volume 11 the most comprehensive book currently available on all aspects related to the 'membrane contactor world.* Describes new unit operations in process engineering* Covers a wide variety of industrial applications, from biotechnology to agrofood* Applicable to process intensification and sustainable growth strategies

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

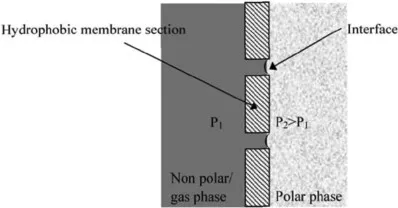

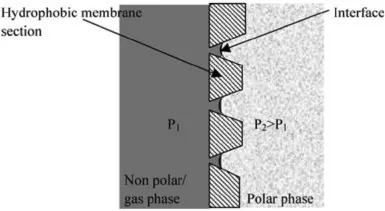

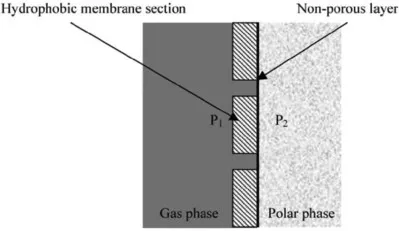

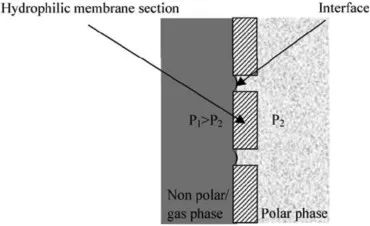

Basic principles of membrane contactors

1 Generalities on membrane contactors operations

Table of contents

- Cover image

- Title page

- Table of Contents

- Membrane Science and Technology Series

- Front Matter

- Copyright page

- Introduction

- Chapter 1: Basic principles of membrane contactors

- Chapter 2: Membrane materials

- Chapter 3: Module configurations and design

- Chapter 4: Gas – liquid systems

- Chapter 5: Liquid – liquid extractions

- Chapter 6: Membrane Distillation and Osmotic Distillation

- Chapter 7: Membrane Crystallization

- Chapter 8: Membrane Emulsification

- Chapter 9: Supported liquid membranes

- Chapter 10: Mass transfer with chemical reaction

- Chapter 11: Relevant applications

- Nomenclature

- List of symbols

- Names list

- Topics list