eBook - ePub

Developments in Surface Contamination and Cleaning - Vol 6

Methods of Cleaning and Cleanliness Verification

- 208 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Developments in Surface Contamination and Cleaning - Vol 6

Methods of Cleaning and Cleanliness Verification

About this book

In this series Rajiv Kohli and Kash Mittal have brought together the work of experts from different industry sectors and backgrounds to provide a state-of-the-art survey and best-practice guidance for scientists and engineers engaged in surface cleaning or handling the consequences of surface contamination.

The expert contributions in this volume cover important fundamental aspects of surface contamination that are key to understanding the behavior of specific types of contaminants. This understanding is essential to develop preventative and mitigation methods for contamination control. The coverage complements the treatment of surface contamination in vol.1, Fundamental and Applied Aspects. This volume covers: Sources and Generation of Particles; Manipulation Techniques for Particles on Surfaces; Particle Deposition and Rebound; Particle Behavior in Liquid Systems; Biological and Metallic Contamination; and includes a comprehensive list of current standards and resources.

- Comprehensive coverage of innovations in surface contamination and cleaning

- Written by established experts in the contamination and cleaning field

- Each chapter is a comprehensive review of the state of the art

- Case studies included

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Developments in Surface Contamination and Cleaning - Vol 6 by Rajiv Kohli,Kashmiri L. Mittal in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Física. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Removal of Surface Contaminants Using Ionic Liquids

Rajiv Kohli, The Aerospace Corporation, Houston, TX, USA

Outline

1. Introduction

2. Surface Cleanliness Levels

3. Ionic Liquids

3.1. Background

3.2. Abbreviations and Nomenclature

3.2.1. Cations

3.2.2. Anions

3.2.3. Alkyl Groups (Rn where n = 1, 2, 3, 4, …)

3.3. General Characteristics

3.4. Thermal Properties

3.5. Volatility

3.6. Solubility Considerations

3.7. Modeling and Predictions of Thermodynamic Properties

3.8. Viscosity

3.9. Electrical Conductance and High Vacuum Analytical Applications

3.9.1. Electron Microscopy

3.9.2. Surface Analysis

3.10. Toxicity Concerns

3.11. Data Compilations

3.12. Deep Eutectic Solvents

4. Principles of Cleaning with ILs

4.1. Basic Principles

4.2. Cost Considerations

5. Advantages and Disadvantages of ILs

5.1. Advantages

5.2. Disadvantages

6. Applications

6.1. Semiconductor Cleaning

6.2. Brush Cleaning

6.3. Parts Cleaning

6.4. Electropolishing

6.5. Cleaning with ILs and Supercritical Gases

6.6. Cleaning of Oil-Contaminated Sands and Particulate Matter

6.7. Decontamination of Hazardous Materials

6.8. Microbial Contamination

6.9. Cleaning in Place

6.10. Cleaning of Artworks

6.11. Industrial Applications

6.11.1. Hydrocarbon Production

6.11.2. Fuel Desulfurization

6.12. Consumer Product Applications

7. Summary and Conclusions

Acknowledgment

Disclaimer

References

1 Introduction

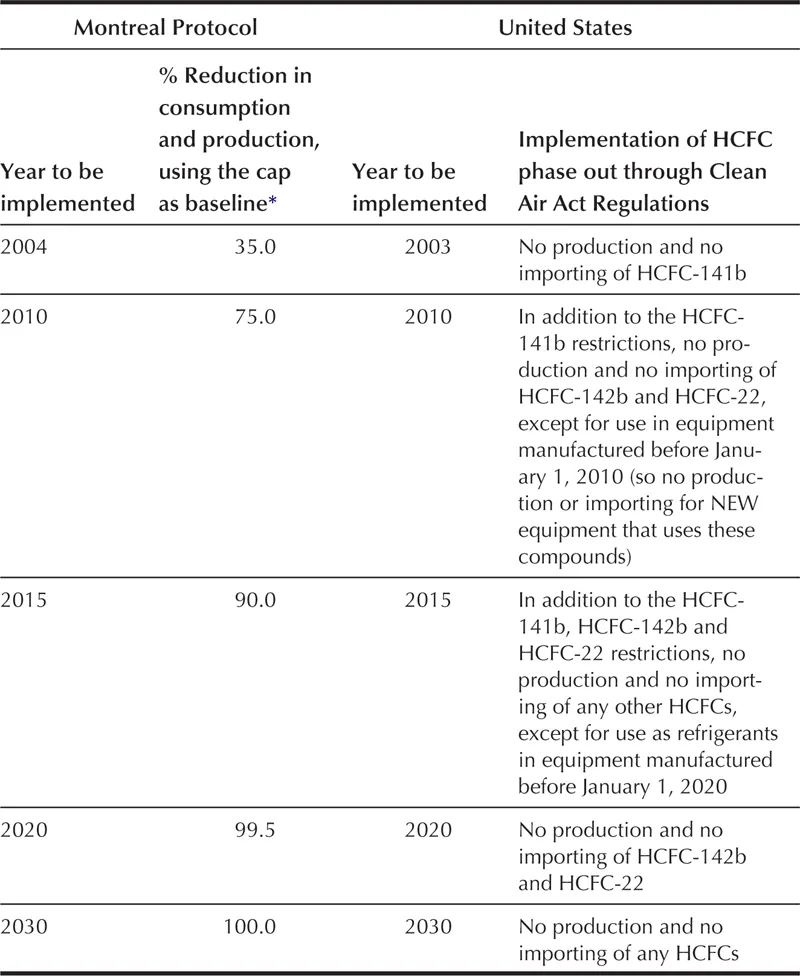

Conventional solvents, such as chlorinated compounds, hydrochlorofluorocarbons (HCFCs), trichloroethane and other ozone-depleting solvents (ODCs), are commonly used for industrial and precision cleaning in a variety of applications. Many of these solvents are deemed detrimental to the environment [1,2]. Concerns about ozone depletion, global warming, and air pollution have led to new regulations and mandates for the reduction in the use of these solvents. In fact, there is a specific schedule for the United States to phase out its production and consumption of HCFCs in accordance with the terms of the Montreal Protocol as shown in Table 1.1 [3]. The search for alternate cleaning methods to replace these solvents has led to the consideration of various alternative cleaning substances and technologies.

TABLE 1.1

Comparison of the Montreal Protocol and United States Phase Out Schedules for HCFCs

∗The cap for developed countries is set at 2.8% of that country’s 1989 chlorofluorocarbon consumption plus 100% of that country’s 1989 HCFC consumption.

[3]

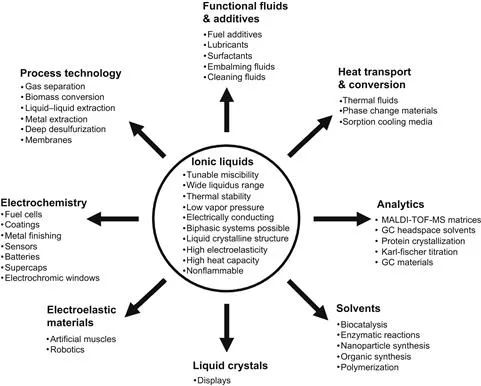

Ionic liquids (ILs)1 are a new class of materials with unusual and unique properties that make them attractive as process and performance chemicals for a wide range of applications [4–49]. These applications include electrodeposition, electrosynthesis, electrocatalysis, electrochemical capacitor, lubricants, embalming fluids, biocatalysis, plasticizers, solvents, lithium ion batteries, fuel cells, solvents to manufacture nanomaterials, extraction, gas absorption agents, energetic materials for propulsion, and other applications. Figure 1.1 summarizes important properties of ILs and their current and potential applications. Recently, cleaning applications have been proposed and demonstrated. The focus of this chapter is on developments in ILs for removal of surface contaminants.

FIGURE 1.1 Current and potential applications of ionic liquids (MALDI-TOF-MS = Matrix-assisted laser desorption/ionization time-of-flight mass spectrometry; GC = Gas chromatography).

2 Surface Cleanliness Levels

Surface contamination can be in many forms and may be present in a variety of states on the surface. The most common categories include the following:

• Particles

• Thin film or molecular contamination that can be organic or inorganic

• Ionic contamination

• Microbial contamination.

Other contaminant categories include metals, toxic and hazardous chemicals, radioactive materials, and biological substances that are identified for surfaces employed in specific industries, such as semiconductor, metals processing, chemical production, nuclear industry, pharmaceutical manufacture, and food processing, handling, and delivery.

Common contamination sources can include machining oils and greases, hydraulic and cleaning fluids, adhesives, waxes, human contamination, and particulates. In addition, a whole host of other chemical contaminants from a variety of sources may soil a surface. Typical cleaning specifications are based on the amount of specific or characteristic contaminant remaining on the surface after it has been cleaned.

Most precision technology applications require characterization of particles, as well as nonvolatile residue (NVR). For example, civilian and defense space agencies in the United States (NASA, National Aeronautics and Space Administration; DoD, Department of Defense) and Europe (ESA, European Space Agency) specify surface cleanliness levels for space hardware in the microparticle size range [50,51]. The cleanliness levels are based on contamination levels established in the industry standard IEST-STD-CC1246D for particles from Level 1 to Level 1000 and for NVR from Level AA5 (10 ng/0.1 m2) to Level J (25 mg/0.1 m2) [52].

The cleanliness levels commonly used by NASA to specify particle and NVR contamination for space hardware are 50 A, 100 A and 300 A (A = 1 mg/0.1 m2) [50], although for other applications stricter cleanliness levels may be specified, such as Level 10 for particles and Level A/5 (200 µg/0.1 m2) or A/10 (100 µg/0.1 m2) for NVR [53]. In many other commercial applications, the precision cleanliness level is defined as an organic contaminant level less than 10 µg/cm2, although many applications are setting the requirement at 1 µg/cm2 [50]. These cleanliness levels are either very desirable or required by the function of parts such as metal devices, machined parts, electronic assemblies, optical and laser components, precision mechanical parts, and computer parts.

3 Ionic Liquids

There is a vast amount of published scientific literature on the synthesis, characterization, properties and applications of ILs, represented by Refs [4–49] and the citations therein. No attempt is made to review and summarize the extensive available information except as it relates to surface cleaning. In the following sections, we provide a brief overview of ILs and their characteristics conducive to surface cleaning.

3.1 Background

ILs refer here to purely ionic, salt-like materials that are in liquid form at unusually low temperatures. Broadly defined, ILs are compounds which are liquid below 373 K. More commonly, ILs have melting points below room temperature; some of them even have melting points below 273 K. In general, large and bulky organic cations are combined with weakly coordinating organic or inorganic anions with low-symmetry structures to form the IL. These factors tend to reduce the lattice energy of the crystalline form of the salt and prevent efficient ion lattice packing, resulting in weak coulombic interactions that lower the melting point to give room temperature liquids rather than high-melting solids. Upon mixing, these components turn into liquid at about 313 K or less, and the mixture behaves like an IL.

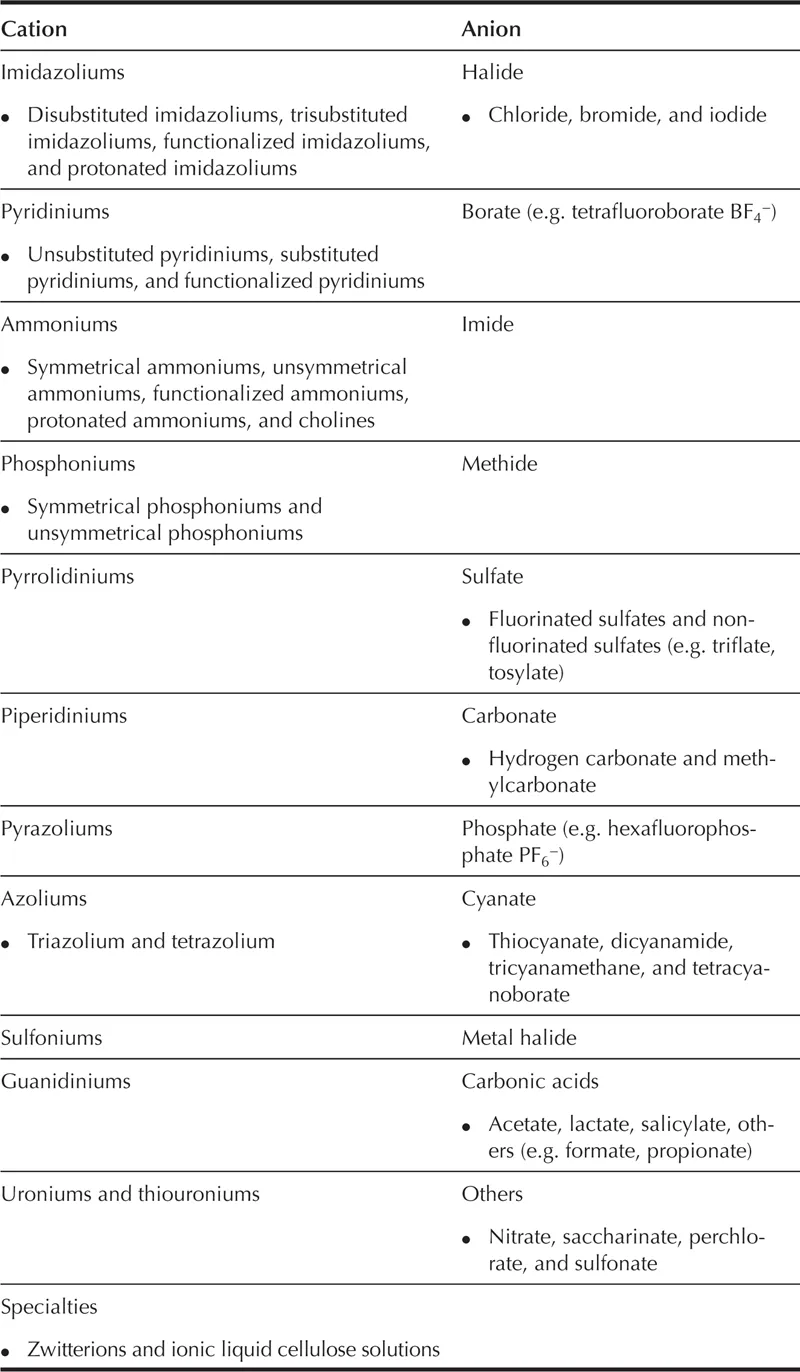

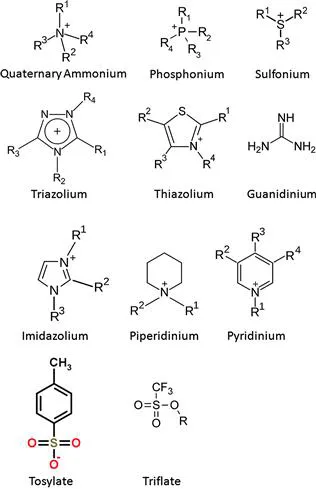

Some of these salts may have a nitrogen-containing aromatic moiety as the cationic component. Other salts may have a phosphorous-containing cationic component. Typical anionic components of these salts include, but are not limited to, methylsulfate, PF6−, BF4−, or halides. Table 1.2 lists the cations and anions that have been used to make ILs. Figure 1.2 shows the structure of more common cations and anions.

TABLE 1.2

Typical Cations and Anions Used for Making Ionic Liquids

FIGURE 1.2 Structures of typical cations and anions used for making ionic liquids. R is an alkyl group or an aryl group.

The cation, anion, and alkyl chain moieties can be adjusted and mixed such that the desired solvating properties, viscosity, melting point, and other properties can be customized for the intended application. These customized ILs are often referred to as “designer solvents”.

The combination of a wide range of cations and anions leads to a very large number of possible single-component ILs that could be synthesized, with 1012 binary and 1018 ternary systems possible. In fact, the number is essentially infinite if we consider quaternary and higher combinations. In reality, the number is of the order of a few thousand ILs that have been described, of which a few hundred are commercially avail...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- About the Editors

- Contributors

- Chapter 1. Removal of Surface Contaminants Using Ionic Liquids

- Chapter 2. Microemulsions for Cleaning Applications

- Chapter 3. Dual-Fluid Spray Cleaning Technique for Particle Removal

- Chapter 4. Microbial Cleaning for Removal of Surface Contamination

- Chapter 5. Cleanliness Verification on Large Surfaces: Instilling Confidence in Contact Angle Techniques

- Color Plates

- Index