Advanced Gear Manufacturing and Finishing

Classical and Modern Processes

- 240 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Advanced Gear Manufacturing and Finishing

Classical and Modern Processes

About this book

Advanced Gear Manufacturing and Finishing offers detailed coverage of advanced manufacturing technologies used in the production of gears, including new methods such as spark erosion machining, abrasive water jet machining, additive layer manufacturing, laser shaping, and sustainable manufacturing of gears.The industry in this area is constantly producing new settings where gears must endure ever increasing stresses, strains, and temperatures. Advanced methods in manufacturing, finishing, and surface property enhancement have emerged in recent years to meet these challenges.This unique book takes a critical look at the state-of-the-art research into these new methods, and the latest improvements to classic technologies in both gear manufacturing and finishing. This book is essential reading for researchers and engineers working in the fields of powertrain manufacturing, gear technology, and advanced manufacturing technologies.- Describes the machining systems, main components, and working procedures with the help of diagrams and photos.- Demonstrates the mechanisms and capabilities of new methods.- Shows improvements to a range of gear manufacturing and finishing technologies.- Provides a critical review of recent research in a range of fields relevant to gear manufacturing technologies.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Introduction to Gear Engineering

Abstract

Keywords

1.1 Introduction and History of Gears

1.1.1 Introduction

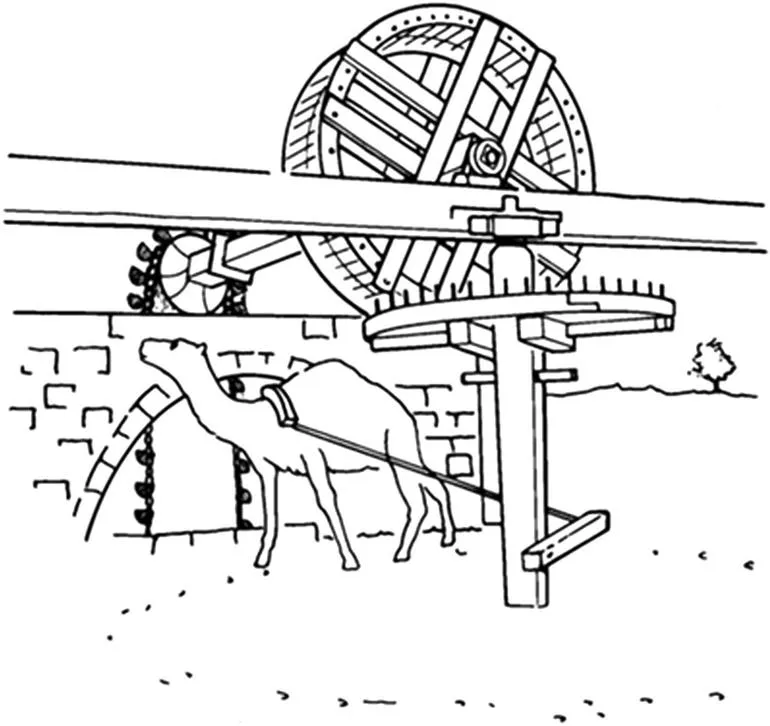

1.1.2 History

1.2 Classification and Gear Types

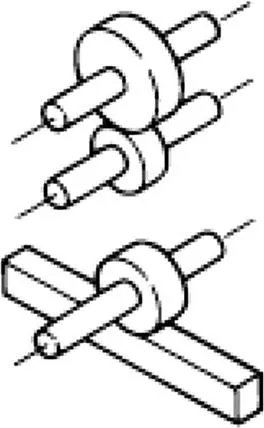

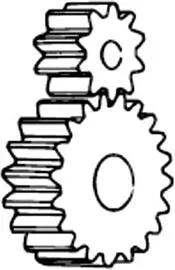

| Categories of Gears (Based on the Orientation of Gear Shafts) | Types of Gears | Representation | Features, Applications and Methods of Manufacture |

Parallel-shaft gears  | Spur gears |  | Features: Simple to design and manufacture, highest efficiency, easy to assemble, offer excellent precision, high wear and noisy operation |

| Applications: Automotive transmission; Industrial drives; Machine tools; Motors and pumps; Agriculture equipment; Scientific instruments; Electronic devices; Large mills | |||

| Methods of Manufacture: Hobbing, shaping, milling, broaching, casting, extrusion, stamping, powder metallurgy, ... |

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- Chapter 1. Introduction to Gear Engineering

- Chapter 2. Conventional Manufacturing of Cylindrical Gears

- Chapter 3. Manufacturing of Conical and Noncircular Gears

- Chapter 4. Advances in Gear Manufacturing

- Chapter 5. Conventional and Advanced Finishing of Gears

- Chapter 6. Surface Property Enhancement of Gears

- Chapter 7. Measurement of Gear Accuracy

- Index