- 348 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Waste Minimization and Cost Reduction for the Process Industries

About this book

The purpose of this book is to provide a base of information and analysis to assist in implementation of the policy of reducing and/or minimizing hazardous waste generation in manufacturing and more specifically in the process industries. What is the significance of reducing the generation of all process wastes? This book examines the technical nature of waste reduction and the extent to which waste reduction can likely be implemented. Also explored is the extent to which technology itself, as well as information and resources, is a barrier to waste reduction. In what ways are waste reduction decisions dependent on specific circumstances? Can the amount of feasible waste reduction be estimated? Auditing of manufacturing and unit operations and processes are particularly significant and useful in the chemical process industries (food, pharmaceuticals, chemicals, fertilizer, petrochemicals, etc.) since it is estimated that these industries account for more than half of the hazardous wastes generated. This book presents a compilation of complete information on potential sources of waste loss or generation through technical inspection. Also presented are calculation methods for determining air-waste-solid wastes material balances, informational requirements and waste reduction analysis.The reader should find the book useful in the areas of auditing and waste minimization. It is replete with useful information as well as specific case histories, which should make it a practical tool for the user.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Waste Minimization and Cost Reduction for the Process Industries by Paul N. Cheremisinoff in PDF and/or ePUB format, as well as other popular books in Biological Sciences & Environmental Science. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Waste Reduction

Waste reduction is an economically sensible response to what many people see as a hazardous waste crisis. Several thousand pounds of hazardous waste are generated annually for every person in the world. Many thousands of people have lost their drinking water because of contamination by toxic waste. Across the world there are thousands of sites contaminated by hazardous waste that require billions of dollars for cleanup. An increasing number of lawsuits are being brought by people who claim to have suffered adverse health effects from living near toxic waste sites. Also the number of lawsuits being instituted by governments is mounting rapidly. Suits claim that certain waste generators have not complied with regulations and that generators who have used waste management facilities must pay for cleanups. More significant is the fact that such processes are inefficent and more expensive than they should be.

Waste reduction and waste auditing is critical to the prevention of future hazardous waste problems. By reducing the generation of waste, materials can be used more efficiently and achieve more certain protection for health and the environment. At the same time, industry can lower waste management and regulatory compliance costs, liabilities, and risks.

Although there are many environmental and economic benefits to waste reduction, over 99 percent of environmental spending is devoted to controlling pollution after waste is generated. Less than 1 percent is spent to reduce the generation of waste. Since many hazardous substances are not as yet regulated, annual expenditures, in all likelihood, will continue to increase in light of risks and liabilities involved and irregardless of regulation changes.

Reducing waste to prevent pollution from being generated at its source is now a practical way to complement costly pollution control as well as being economically desirable in many cases. Because of sporadic and uneven enforcement, the current regulatory system weakens the incentive to reduce waste. Waste reduction, no matter how far it is taken, cannot eliminate all wastes, but it can help to lower costs for environmental protection as economics continue to expand.

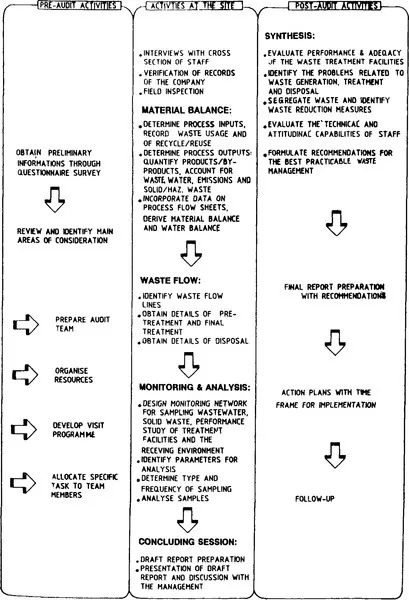

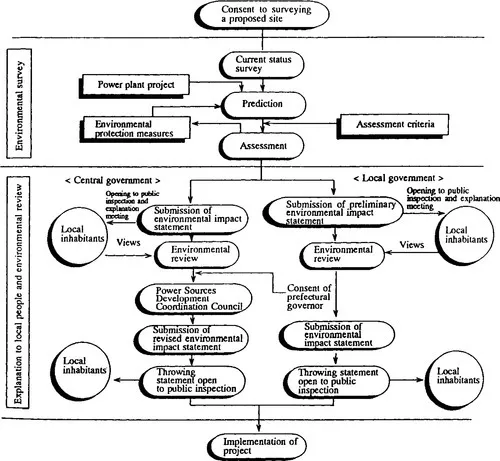

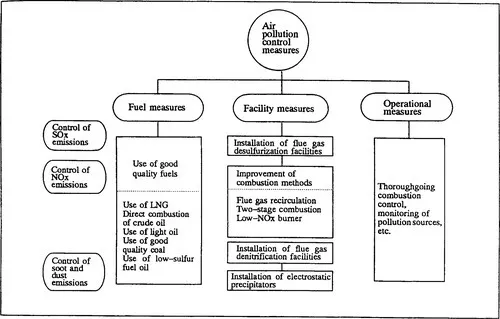

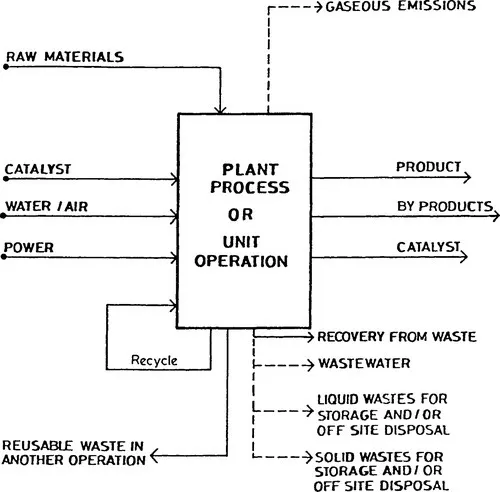

Figures 1 through 4 show typical audit data requirements that preceed any waste reduction program.

Figure 1-1 Environment audit procedure.

Figure 1-2 A flow of the environmental impact assessment process (in the case of a thermal power plant project).

Figure 1-3 An outline of air pollution control measures.

Figure 1-4 A typical unit operation material balance.

Definitions Used in This Book

Waste Reduction: In–plant practices that reduce, avoid, or eliminate the generation of hazardous waste so as to reduce risks to health and environment and improve productivity. Actions taken away from the waste generating activity, including waste recycling or treatment of wastes after they are generated, are not considered waste reduction. Also, an action that merely concentrates the hazardous content of a waste to reduce waste volume or dilutes it to reduce degree of hazard is not considered waste reduction. This definition is meant to be consistent with the goal of preventing the generation of waste at its source rather than controlling, treating, or managing waste after its generation.

Hazardous Waste: All nonproduct or product hazardous outputs from an industrial operation into all environmental media, even though they may be within permitted limits. This is broader than the legal definition of hazardous solid waste. Hazardous refers to harm to human health or the environment and is broader than the term "toxic." For example, wastes that are hazardous because of their corrosivity, flammability, explosiveness, or infectiousness are not normally considered toxic.

Waste Audit: The inventory and information gathering aspect to determine how much; composition and other data which defines waste reduction and hazardous waste.

Current pollution control methods often do little more than move waste around. For example: air and water pollution control devices typically generate solid, hazardous waste that goes to landfills and too often leaches from there into groundwater. Many hazardous wastes, such as most toxic air emissions, and permissible emissions legally sanction the generation of some wastes. Establishing a comprehensive, multimedia approach to reducing wastes going into the air, land, and water is essential.

There is no common definition of waste reduction. There are few or no data on the extent of industrial waste reduction. Waste reduction is usually measured and the information that is collected on waste generation is generally not useful for waste reduction. If waste reduction is defined to include waste treatment, companies will naturally pay more attention to treatment, which is a familiar activity, than to the reduction of waste. Problems of definition and lack of information should be addressed and ongoing waste reduction efforts should be documented by auditing even if decisions to reduce waste remain at the discretion of individuals.

Despite some claims to the contrary, advantage is not taken of all effective waste reduction opportunities that are available. Reducing waste involves more than buying a black box, reading the directions, and plugging it in. Even a simple step toward waste reduction can seem difficult with few technical resources and no obvious place to go for guidance. Reducing waste in an industrial process requires intimate knowledge of all aspects of that specific production process, in contrast to waste treatment, which is essentially an add on to the end of the process. There are also clear pressures to reduce waste tomorrow, rather than today. The attention and resources given to required pollution control activities limit the amount of thought, time, and money that industry can devote to waste reduction. Some, however, have verified the fact that waste reduction pays for itself quickly, especially when compared to the time needed to comply with regulations, obtain regulatory permits, or site waste management facilities. Some are even beginning to sell new products and services that help others to reduce waste.

Waste reduction succeeds when it is part of the everyday consciousness of those involved with production—where the waste reduction opportunities are—rather than when it is a job only of those responsible for complying with environmental regulations. A few people with end–of–pipe, pollution control jobs are not in a position to reduce waste by themselves; such efforts must involve upstream workers, facilities and management.

Waste Reduction Approaches

There are five approaches that industry can take to reduce hazardous waste including:

• change the raw materials of production,

• change production technology and equipment,

• improve production operations and procedures,

• recycle waste within the plant, and

• design or reformulate end–products.

Opportunities that exist for common processes and wastes are:

• using mechanical techniques rather than toxic organic solvents to clean metal surfaces,

• using water–based raw materials instead of materials based on organic solvents, and

• changing plant practices to generate less hazardous wastewater

• improve housekeeping and materials handling procedures.

So far regulators have not required waste reduction. The impact on industry, particularly on troubled manufacturing sectors, could be substantial. Alternatively, we could move to an economically sensible environmental protection strategy based on both pollution control (waste management) and pollution prevention (waste reduction) with auditing providing leadership and assistance.

The first need is policy development, education, and oversight. Also, there is a need for innovative engineering and management. Opportunities are embedded in every part of the industrial production system. There is no way to predetermine the amount of waste reduction possible; its technical and economic feasibility depend on the characteristics, circumstances, and goals of specific waste generators. Success in reducing waste depends on the ability of organizations to modernize, innovate, and cut costs, increasing profits and reducing long–term liabilities. Waste reduction could be used as a measure of performance as energy efficiency and productivity often are possible legislative actions that could clarify the definition of waste reduction, spur better collection of information on waste reduction, and encourage more attention to the subject.

BACKGROUND

Environmental protection efforts emphasize control and cleanup of pollution by hazardous substances after they are generated and no longer serve a productive function. Virtually, all industries, whether high technology or other generate hazardous waste. The cost of controlling that waste totals many billions of dollars annually. Usually, hazardous industrial wastes are not destroyed by pollution control methods, but they are put into the land, water, or air where they disperse and migrate. The result is that pollution control for one environmental medium can mean that waste is transferred to another medium or elsewhere.

As the costs of administering environmental programs and the costs of compliance has grown the economic and environmental benefits of reducing the generation of hazardous waste at the source have become more compelling. But it is exactly these requirements and costs of complying with them that both encourage some waste reduction and make it difficult for industry to give waste re...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- About the Author

- Preface

- Notice

- Chapter 1: Waste Reduction

- Chapter 2: Auditing

- Chapter 3: Waste Minimization Data/Information Requirements—A General Approach For Manufacturing—

- Chapter 4: Estimating Releases to the Environment

- Chapter 5: Waste Questionnaires Water Control Checklist

- Chapter 6: Analysis of Process Chemistry Example Processes

- Chapter 7: Industry Profile—Fertilizers

- Chapter 8: Treatment of Effluent Fertilizer Industry Example

- Index