- 292 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Composite Materials

About this book

The contributions in this volume bring together the experience of specialists on the highly complex technology required for manufacturing composite structural parts, presenting fundamental descriptions of the processing and properties of these advanced materials.The 34 papers give a thorough overview on recent advances in this field. The contributions have been collected in two general categories: composites based on organic matrices; and composites based on inorganic matrices. In each group properties and manufacturing technologies are analyzed together with long term durability and the special applications for such advanced materials.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Composites with Organic Matrices

Modelling of Processing Technologies for Polymer Matrix Composites

Jose M. Kenny Department of Materials and Production Engineering, University of Naples, P. Tecchio, 80125, Naples, ITALY

Abstract

A general model for the description of the thermo-chemo-rheological changes of the matrix during the processing of polymer based composites, has been developed in recent years. The master model includes, specific submodels dedicated to the different physico-chemical aspects of composite processing: reaction kinetics, heat transfer, viscosity, fluid flow and void formation during processing. The main objective of this work is to highlight the contribution of the understanding of the matrix behaviour to the right choice of processing conditions.

MODELLING PRINCIPLES FOR COMPOSITES PROCESSING

In the last decade several studies of the fundamental aspects of the processing of high performance composites have been reported [1–6]. In those research works a common scientific approach based on the understanding of the fundamental chemical and physical phenomena governing the behaviour of the composite matrix and allowing a better choice and control of processing conditions has been developed.

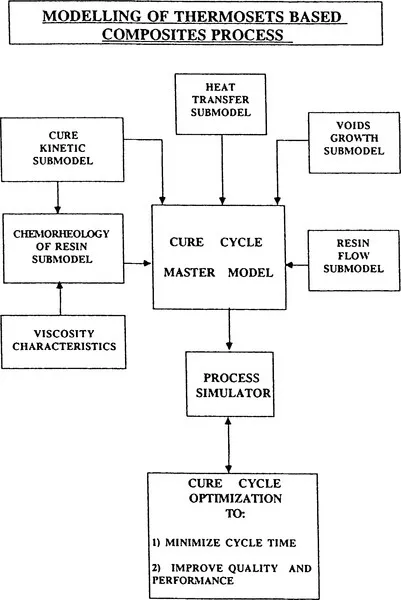

The final objective of those activities was the construction of a general processing model that could be adapted to different specific technologies. In order to develop such general model several submodels are needed as shown in Fig. 1. The first submodel describes the kinetics of the matrix chemical transformations, responsible of the final structure of the composite. The thermokinetic model predicts the exothermal heat of reaction and the degree of cure as a function of process time and temperature. The rheological model describes the viscosity evolution as function of time, temperature and degree of cure. Therefore, the rheological model is combined with the thermokinetic model forming the chemorheologicał model including also the gel point. For non-isothermal conditions also a heat transfer model is needed. If the heat transfer model is combined with the chemorheologicał and cure kinetic models, the degree of cure, temperature and viscosity, as a function of time and position in the composite, can be predicted. The flow model predicts resin content distribution and final composite thickness. Finally, the void model predicts the conditions needed to avoid the formation of voids.

Figure 1 Modeling philosophy of the processing of composite materials

A more detailed examination of the modelling of composite processing technologies will be given in the following sections where each of the submodels mentioned in this section, integrated into a general master model, will be discussed.

THERMOKINETIC MODEL

The thermokinetic model is the first step in the construction of the master model being a prerequisite for all the other submodels. It describes the rate at which heat is given off during the reaction, and the degree of cure, α, as a function of temperature and time. For curing reactions, the rate of heat flow dH/dt, can be conveniently measured by differential scanning calorimetry (DSC) [7]. It has been assumed for these processes that the quantity dH/dt is directly proportional to the rate of disappearance of reactive groups during curing, dα/dt. Empirical thermokinetic models for non-autocatalytic reactions have usually the following form:

Integration of this equation can be used to predict α, dα/dt and dH/dt as a function of time and temperature. The rate constant K depends on temperature and generally is given by:

KO is a preexponencial factor (frequency factor), E is the activation energy, R is me gas constant and T the absolute temperature. A much better description of the thermoset behavior has recently been reported [8]:

where αm is the maximum degree of reaction obtained at a given temperature in an isothermal test. For reactions with autocatalytic behavior the following rate equation has been ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Preface

- Symposium Information

- Part I: Composites with Organic Matrices

- Part II: Composites with Inorganic Matrices

- Author Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Composite Materials by A.T. Di Benedetto,L. Nicolais,R. Watanabe in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.