- 190 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Health, Safety and Ergonomics

About this book

Health, Safety and Ergonomics provides an account of the part ergonomics play in the improvement of working conditions. The book begins with the presentation of the advantages of ergonomics intervention. Subsequent chapters focus on the discussion of the principles, applications, and methods of ergonomics such as assessment and prediction of human reliability, hazard awareness and risk perception, and work-related musculo-skeletal disorders. Manufacturing automation, the cost of ergonomic limitations, and the direct benefit from ergonomics action on health and safety are elucidated as well. Ergonomics researchers, health and safety engineers, and production managers will find the book useful.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Health, Safety and Ergonomics by Andrew S. Nicholson,John E. Ridd in PDF and/or ePUB format, as well as other popular books in Médecine & Santé publique, administration et soins. We have over one million books available in our catalogue for you to explore.

Information

Part 1

The role of ergonomics

Chapter 1

The advantages of ergonomics intervention

E.J. Cullen

Publisher Summary

This chapter discusses the advantages of ergonomics intervention. The importance of ergonomics in the prevention of accidents and ill health at work brings together many diverse areas of ergonomics for discussion in relation to the improvement of occupational health, safety, and efficiency. It is important to recognize that any ergonomics principles applied to health and safety can also result in other benefits, such as increased efficiency and better worker morale. The application of ergonomics principles is therefore essential to good occupational health and safety practice for all work activities. These principles are considered frequently in relation to high-hazard industries. The proper design of the man–machine interfaces of control rooms and operating procedures can lessen the chance of human error. The rapid technological change involves the introduction of computers and visual display units that have had an impact in the office as well as in the factory. It should be recognized that these ergonomics principles can be applied as effectively in the office as elsewhere. The challenge is to apply existing ergonomics principles in the workplace now and to develop new techniques to overcome existing problems.

This opening chapter does not address a specific topic but introduces an hypothesis that the succeeding chapters set out to consider. The hypothesis presented is that: ‘The application of ergonomics within any and every industry or business can have benefits both for the worker and for the work process in a number of different ways, relating to health, safety and efficiency.’ The text offered here is an edited version of the opening address given by Dr John Cullen, Chairman of the Health and Safety Commission, at the international symposium entitled ‘Workwise: Ergonomics, Health and Safety’.

The importance of ergonomics in the prevention of accidents and ill health at work has been recognized for some time. It is now appropriate to bring together many of the diverse areas of ergonomics for discussion in relation to the improvement of occupational health, safety and efficiency.

Active and extensive co-operation between the Robens Institute of Industrial and Environmental Health and Safety, the Health and Safety Executive (HSE) and the Ergonomics Society led to the ‘Workwise’ symposium in October 1987 and to the subsequent publication of extended presentations in this book.

I am sure that the following chapters will enable the reader to gain a better understanding of the link between occupational ill health, accidents and the manner in which ergonomics may have a direct bearing on their occurrence. This will be of benefit to management decision-making in the design, installation and operation of plant and systems of work and also to the workers who are daily exposed to the effects of poor ergonomic design.

It is important to recognize that any ergonomics principles applied to health and safety can also result in other benefits such as increased efficiency and better worker morale.

In this opening chapter, I wish to take the opportunity to consider three aspects of ergonomics and health and safety at work: (1) to discuss the link between ergonomics and health and safety, and suggest that it affects all our work activities; (2) to consider how ergonomics principles may be applied at the workplace; and (3) to outline two areas where the HSE has been involved in ergonomics considerations during the course of its everyday work.

1.1 Ergonomics, health and safety

Ergonomics, considered in its widest sense, affects all our work activities, from simple everyday things like sitting and writing at a desk or lifting and carrying a load, through to complicated operations such as controlling a nuclear power station.

The application of ergonomics principles is therefore essential to good occupational health and safety practice for all work activities. While these principles are considered frequently in relation to high hazard industries, known principles are, unfortunately, often ignored at plant or shopfloor level.

We therefore need to get the message across that when workers operate in less-than-optimum conditions they will have to increase their effort to maintain efficiency or even to complete the task. This increased effort may lead to immediate error or overstrain resulting in accident or injury (e.g. back injury from manual handling or lifting too heavy a load, a fall from over-reaching when working from a ladder, operating an incorrect machine control) it may also lead to long-term degradation of performance resulting in impaired efficiency and possibly also to physical and mental ill health, e.g. musculo-skeletal disorders particularly of the upper limbs, some of which may be linked to repetitive tasks.

The ‘less-than-optimum conditions’ mentioned above may arise from poor machine design, inappropriate workplace layout, poor posture, environmental constraints or from job stress. You are likely to find examples of these problems while walking around any workplace and may also notice situations where employees have made their own adjustments, e.g. work surfaces that have been raised by placing blocks under table legs, the introduction of home-made foot-rests, seats that have been raised by adding cushions, identical control levers that have been classified by the addition of unusual markers or handles.

These ‘do-it-yourself’ signs often indicate a lack of ergonomic awareness and an underlying problem. Not all employees, or employers, will recognize the problems, nor provide effective remedies; worse still, others will introduce changes which are positively hazardous.

Where particularly the work process is, or is becoming, more complex (for instance, the potentially more hazardous industries such as nuclear power and chemical processing) another branch of ergonomics, that of human reliability or human error analysis, has to be applied. Given a specific situation, particularly a complicated operation under stress, what, then, are the chances of the operator making a mistake? The potential for accidents may be reduced by gaining a better understanding, not only of the work process, but also of the worker.

1.2 Application of ergonomics principles in the workplace

The solution to the problems of industrial injury and ill health is prevention rather than cure. If we accept that applying ergonomics can benefit both the worker and his work, how can we ensure that ergonomics principles are applied at the workplace? This can be done only by convincing industry of the need to apply ergonomics principles, particularly when designing (whether it be machines, plant, workplace layout or the environment) or when drawing-up systems of work. It is only by a thorough examination of work practices that the ergonomics problems (which give rise to accidents or ill health) can be reduced. The chapters in this book address many of the key ergonomics principles, which if applied in a systematic way, would lead to a significant reduction in accidents and ill health. The identification and elimination of problems at the design and planning stage are the measures that are likely to be the most effective and the most economic.

There is no doubt that good design of work systems, tools, equipment and furniture can lessen the likelihood of strain injuries. Anatomical and physical limitations need to be taken into account when new machinery is on the drawing board. Job design is also important to avoid long spells of repetitive or static work.

The proper design of the man–machine interfaces (MMIs) of control rooms and operating procedures, can lessen the chance of human error. The rapid technological change, the introduction of computers and visual display units (VDUs) have had an impact in the office as well as in the factory and it should be recognized that these ergonomics principles can be applied as effectively in the office as elsewhere.

It is perhaps appropriate here to make the point that Section 6 of the Health and Safety at Work etc. Act 1974, obliges designers, manufacturers and suppliers to provide articles and plant that are safe and without risks to health.

Not all problems, however, can be solved at the design stage and, clearly, numerous plants already exist; we must therefore consider the correction of problems from an operational point of view. In many cases, minor modifications to the system of work, to the workplace or to the environment, can be implemented relatively easily to make the work much safer and healthier, e.g. introduction of rest periods, redesign of tool handles, adjustment of the height of a workbench, or redesigning the manual handling process (possibly by replacement with mechanical equipment).

1.3 The Health and Safety Executive’s involvement with ergonomics

I would like to mention here just two areas of interest, namely personal protective clothing and equipment (PPE) as relating to protective clothing and the inclusion of ergonomics in the design process for Sizewell B nuclear power station.

1.3.1 Personal protective clothing and equipment

There is a risk in many working environments that health will be impaired from the direct effects of environmental pollutants – dust, chemicals, noise and thermal radiation – where exposure cannot always be reduced or eliminated by enclosure or control. Special clothing or PPE may then be provided for the workers. However, it has often been found that protection is not worn because it is uncomfortable, or interferes with the ability to perform a task effectively.

A particular area of recent concern has been the problem of comfort and fit for head-mounted equipment such as goggles and respirators. In order to address this problem, the HSE commissioned a study of head and facial dimensions. Anthropometric dimensions from nearly 400 individual heads were collected using a computerized measuring device. Measurements were made on both men and women of various ethnic origins.

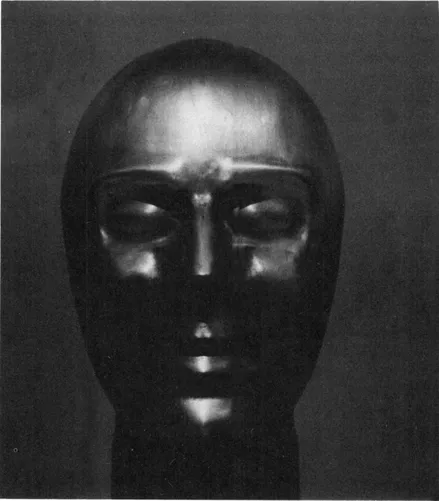

The HSE’s research laboratories have used the data from this survey to generate headform shapes which are representative of the characteristics of particular sections of the working population. A male ‘average’ headform has been produced from this data using computer-aided design (CAD)/computer-aided manufacture (CAM) techniques. It is intended to use the headform relating to eye protectors, and other headforms representative of other sections of the population, in British Standards for PPE as a means of assessing fit characteristics (Figure 1.1).

Figure 1.1 The 50th percentile Caucasian male headform

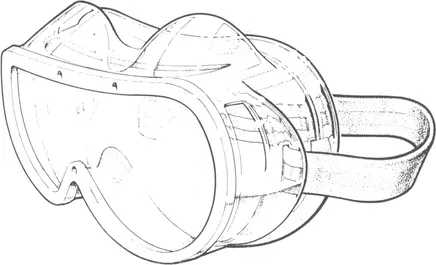

While these data provide the information required to improve both the comfort of, and the work efficiency when, wearing such equipment, PPE has often been reported as interfering for other reasons with a worker’s ability to do a job effectively. An example of this is the use of safety goggles, particularly in hot environments such as foundries where misting affects the wearer’s ability to see (Figure 1.2). A study of misting characteristics in eye protection was undertaken in the HSE’s laboratories. Findings from this research resulted in the patenting of goggle designs which would resist misting. Prototypes based on these patents have been field-tested in several industries to assess their effectiveness and acceptability. These field trials showed that, whereas 55% of wearers experienced considerable misting problems when wearing their normal eye protection, no one encountered such problems with the anti-mist goggles. Discussions are being conducted with manufacturers to arrange for the production of the goggle under licence.

Figure 1.2 The Health and Safety Executive anti-mist goggle

1.3.2 Application of ergonomics in Sizewell B nuclear power station

Sizewell B is being designed with a target probability for the release of radiation of less than ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- Acknowledgements

- Contributors

- Part 1: The role of ergonomics

- Part 2: The operator in the system

- Part 3: User-centred design

- Part 4: Perspectives on current issues

- Index