![]()

Part I

The hydrogen embrittlement problem

![]()

1

Hydrogen production and containment

G.B. Rawls and T. Adams, Savannah River National Laboratory, USA

N.L. Newhouse, Lincoln Composites, Inc., USA

Abstract:

The focus in this chapter is on the review of relevant consensus codes and standards as they relate to the design, manufacture, and operation of pressurized vessels and piping/pipeline system for gaseous hydrogen service. major areas of emphasis for these reviews have centered on the following: (1) material composition and property control, (2) failure mechanism, to include fatigue, (3) design specifications and margins, (4) post-fabrication testing and post-installation evaluation/examination, and (5) impact of leak rates and leakage phenomena. In addition, embedded within the discussions on code and standard requirements are anecdotal accounts of ‘real world’ pressurized hydrogen vessel and piping/pipeline failures and challenges with design. Finally, the overarching goal of this chapter is to indicate the complexity of design of system for pressurized hydrogen service and to demonstrate the significant role that consensus codes and standards play in providing an invaluable framework to helping overcome these challenges through aiding the safe design and operation of pressurized hydrogen systems and components.

Key words

hydrogen containment

hydrogen vessels

ASME Code for Hydrogen

DOT cylinders in hydrogen service

composite vessels in hydrogen service

hydrogen leakage

hydrogen piping

1.1 Introduction

The safe delivery and storage of hydrogen will be imperative to successful implementation of a hydrogen economy. Hydrogen storage and delivery have one common aspect in that all these processes will require pressure vessels and piping systems to safely contain hydrogen and avoid the hazard introduced if hydrogen were to escape the containment boundary. Hydrogen, like all other fuels and flammable gases, has inherent hazards, and vessels containing hydrogen must be carefully designed and manufactured.

This chapter reviews the experience obtained from hydrogen storage and transport vessels. The containment vessels used for the storage and delivery of hydrogen are discussed. Finally hydrogen pipelines used as a delivery mechanism are reviewed. All pressure vessel design codes and standards address requirements for materials, design, fabrication, inspection and testing necessary to produce a quality vessel. Requirements specific to hydrogen fluid service, specifically have been introduced into codes and standards in more recent years.

When the American Society of Mechanical Engineers (ASME) started to develop new Code rules for hydrogen vessels for design pressures up to 100 MPa (15,000 psi) in 2004 the committee reviewed the applicable rules given in the ASME section VIII Code and rules given in Department of Transportation (DOT), International Organization for standardization (ISO) and Natural Gas Vehicles (NGV) standards. The 100 MPa (15,000 psi) limit was set to provide needed storage capacity to refuel to the 70 MPa (10,000 psi) level.

1.2 American Society of Mechanical Engineers (ASME) stationary vessels in hydrogen service

In the last few years, codes and standards activities have been increased considerably to develop rules for high pressure hydrogen storage vessels. When this effort started in 2004 the pressure for hydrogen storage vessels constructed to ASME requirements in general had an upper range of 40 MPa (6000 psi) with an upper limit of 70 MPa (10,000 psi). High pressure storage vessels are constructed using ASME BPV Code section VIII Division 1, Appendix 221. The Appendix 22 scope addresses the design, fabrication, and inspection for integrally forged pressure vessels with a maximum internal diameter of 600 mm (24 in) and a maximum design temperature of 95 °C (200 °F). Vessels in hydrogen service are at the upper pressure limit of 70 MPa (10,000 psi) and are 150–200 mm (6–8 in) in diameter. There is extensive successful experience with the Appendix 22 designs in hydrogen, with over 1500 vessel in service and some with over 15 years of operating service2.

Appendix 22 was specifically added to take advantage of the high strength materials in ASTM SA-3723. The additional requirement in Appendix 22 allow for the ASME Section VIII design margin on the ultimate tensile strength to be lowered from 3.5 to 3.0. The materials used in hydrogen application are SA-372 Grade D, Grade J, Class 65, or Grade J, Class 70, quenched and tempered steel. A maximum usable thickness of SA-372 steel is about 38 mm (1.5 in) and is based on the capacity to satisfactory heat treat the material. Appendix 22 requires the same impact testing requirement as all other Section VIII Division 1 Vessel.

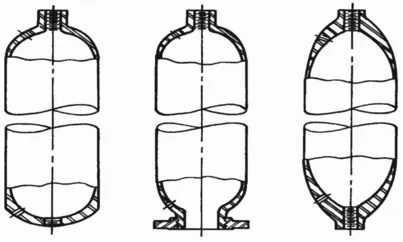

The Appendix 22 vessels are designed to minimize stress concentrations. The shell portion of the vessel is not allowed to have openings or welded attachments. Examples of these vessels are shown in Fig. 1.1. These vessels are fabricated using a billet piercing process. The heads are integrally formed concave to the pressure side and openings in the heads are limited to the lesser of 50% of the inside diameter or nominal pipe size DN 80 (NPS 3). Heat treatment is performed to the requirements of ASTM SA-372 and all Appendix 22 vessels are required to have either a magnetic particle or liquid penetrant examination following the heat treatment.

1.1 Typical Appendix 22 vessels. (from ASME Section VIII1)

Hydrogen containment vessels in the petroleum refining industry have also been constructed using ASME rules. These vessels have generally been welded construction and have upper design pressure levels of 17 MPa (2500 psi). These vessels have been fabricated from Cr–Mo steels. The ultimate tensile strength of these steels in general has been less than 655 MPa (90 ksi). The processing vessels are in high temperature service where hydrogen attack is controlled through the application of the rules of API RP 941, the Nelson Curves4. Details on petroleum refinery vessels are addressed in another section of this book, but one vessel that is common in hydrogen service is the pressure swing adsorption (PSA) vessel.

PSA vessels in hydrogen service are general fabricated from ASTM A516 Grade 70 material and are in high cycle fatigue service. These vessels experience 25,000–250,000 cycles per year depending on if they are used in refinery service or in hydrogen production by an industrial gas supplier. The PSA process has been used since the 1960s for hydrogen gas purification and is used on other gas purification processes as well. Failure in PSA vessels led to some additional rules to control weld peaking that were published in the 1999 Addenda to ASME Section VIII Division 25. The available data are not clear about the contribution for acceleration of fatigue crack growth rates for a ...