Chapter One. Introduction

As the engineer's saying goes, defining the problem is the first step toward solution. Understanding the processes, the volume, process time, quality and other measurements of the product lifecycle is the first step toward best-in-class design, development, configuration management, supply chain and product manufacturing.

Most product manufacturing organizations know the number of new products they release, the number of new specs and drawings they release, and the number of changes they make in any given period of time. Less than a third measure the change process time precisely according to the author's benchmarking survey of 58 product manufacturing companies. In fact, of the 31% that said they measure the change process time precisely, only four were willing to furnish their report. Does this mean that most of the 31% thought they knew their process time but didn't actually measure it? Or only measured a part of the process? Or that they had only measured the process speed at a snapshot in time? Does this mean that two-thirds or more of product manufacturing companies do not feel that speed in the change process is important? If a change is worth doing, isn't it worth doing fast?

Faster processing of new item releases, requests for engineering action, redesign and incorporation of changes and related functions is critical to profitability. If a change is required to meet specification, should we ship more products without that change? If a change will accomplish a real cost reduction should we build more products at a higher cost? If a change can logically be processed slowly, it probably shouldn't be done at all (methods of screening out unneeded or unwise changes are included). This writer would submit that any change worth doing is worth doing fast. Not at the sacrifice of quality, however – neither the quality of the change nor the quality of the product. This same analysis can be applied to the release process, request process, and every other CM and related process.

What is CM?

Let's first identify the basic “raw materials” of product manufacturing – the very essence of product manufacturing. There are three primary elements:

• Tools (machine, mold, software, etc.)

• People (and the processes they choose to follow)

• A product (embodied in design drawings, specs and code).

So why then is it a surprise for some to hear that the process control of those design documents is a critical discipline? Think about it. Without design documents, you have no product or at least no ability to produce a repeatable product. Without processes to control design documents you have chaos. Without those processes being fast, accurate, documented, measured and well understood you have serious efficiency or cost issues. Issues which take/steal time from engineers to product-innovate and manufacturing to process-innovate. Creating fast, accurate, measured, documented and well-understood processes will thus set the stage for innovation.

Why is the revelation that the processes are the very essence of business a surprise to anyone? Why do we continue to see processes in business, in government, on the internet, and in our daily lives so convoluted, complicated and non-intuitive as to be ludicrous? Without; make sense, fast, accurate and measured processes you also have a touch (or more) of insanity.

Setting the stage for innovation

An article the author wrote for APICS e-News (Feb. 2005) may help define the discipline:

“The basic raw materials for product manufacturing are tools (including software), people (the processes they choose) and the design documents. Not withstanding this basic truth, most companies have a gap between Engineering and Manufacturing/Operations people, processes and systems with regard to design documents.

Engineering people tend to be very analytical and cautious. Manufacturing people tend to be movers and doers. Manufacturing people say that engineers frequently ‘throw it over the wall’. Engineering people say they ‘can't find anyone who knows how the new product will be processed’. Manufacturing folks say‘Engineering is always changing the design’. While engineering people say ‘Manufacturing people are always changing the process’. Their respective processes tend to end at the water's edge, sometimes with endless meetings intended to bridge the gap between them.

Manufacturing folks have purchased MRP/ERP systems and Supply Chain systems. Engineering purchased CAD/PDM/PLM systems. These systems seldom ‘talk to each other’. Multiple Bills of Material and other major problems result.

A plethora of manufacturing and supply chain papers, articles and software programs seem to assume the availability of the right document, at the right place, at the right time. Many folks are caught up in the ‘buy a new system to solve the problem’ mode. Few seem to be working on bridging the gap/tearing down the wall between engineering and operations.

Note what Morris and Brandon wrote in Re-engineering Your Business: ‘To be sure, information technology was used to support the new process, but the process redesign came first and the technology considerations second.’ Also what Mitch Ratcliffe wrote in Technology Review: ‘A computer lets you make more mistakes faster than any invention in human history … with the possible exceptions of handguns and tequila.’

Yes, software solutions can help us get the right document to the right place at the right time, if (that big word) we have a process in place requiring that to happen. Much more attention needs to be focused on the design documentation/CM processes before jumping to ‘the software solution’. This is true whether we are talking about manufacturing in house or via the supply chain. One needs only to analyze the root cause for ‘bad parts’ that end up on the dock or the manufacturing floor. Or analyze the root cause when customers receive a different configuration of a product than they wanted. Why do materials/supply chain people often have parts they don’t need and/or are short of parts they do need? How many of the productchanges are thought to be ‘cost reductions’ but aren't? This writer's experience says that the technical document processes, or lack thereof, are the root cause of a vast majority of manufacturing problems.

We need to bridge the gap between engineering and manufacturing people, processes and systems. Design the engineering documentation processes first, establish meaningful metrics, streamline the processes with legacy systems, then seek new software to facilitate that process design. Focusing on the processes first is the next great frontier for continuous improvement.”

Another way of viewing the CM function is as the quality assurance function for the design and related technical documentation. CM should assure that the right person reviews the new or changed documents, at the right time, signs same, and that all document-related standards (drafting manual and CM standards) are followed. Also, CM should assure that the processes are measured and reported as appropriate to highlight problems or progress. We need to carry out these functions whether we are criticized, demonized or praised. In the long run an appreciation for the CM function will evolve.

Bridge the gap

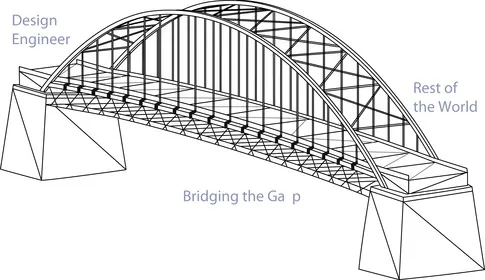

Another way of viewing the Configuration Management organization is as the communications bridge between Design Engineering and the rest of the world (see Fig. 1.1).

Communication may be the single most important function performed by the CM organization. Communications about the process and the documentation are critical to the product lifecycle profitability. Process measurement is a basic necessity to this communication. Design the control processes, document them, communicate them and measure them.

The measurements must be associated with all the traffic across the bridge – in both directions. Some of that traffic is of the significance of an 18-wheeler and other traffic has the significance of a walking tourist. Thus there should be a degree of significance about our measurements.

These metrics should generally be prepared by the CM manager and the CM technicians. If a key metric is prepared by another department, the CM manager should make sure it is communicated to the right people at the right time. Much of the work in preparation of the metrics discussed here (and applicable to a particular company/division) is best done by the CM function.

It is sometimes the case that no CM function exists and even if the function exists, it is not properly manned. It is often “buried” too deep in the organization. It should answer to the Chief Engineer or to the Director of Engineering Services – executive management take note. It must also be properly manned – typically with technicians.

• Principle: The CM function, properly chartered and manned, becomes the Quality Assurance function for the company design and related technical documentation processes.

CM Processes

In order to organize the discipline and this book, we will address the important metrics in the major CM processes and closely related processes:

• Order entry/fulfillment