- 648 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

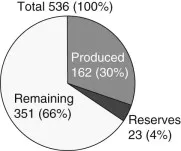

Crude oil development and production in U.S. oil reservoirs can include up to three distinct phases: primary, secondary, and tertiary (or enhanced) recovery. During primary recovery, the natural pressure of the reservoir or gravity drive oil into the wellbore, combined with artificial lift techniques (such as pumps) which bring the oil to the surface. But only about 10 percent of a reservoir's original oil in place is typically produced during primary recovery. Secondary recovery techniques to the field's productive life generally by injecting water or gas to displace oil and drive it to a production wellbore, resulting in the recovery of 20 to 40 percent of the original oil in place.In the past two decades, major oil companies and research organizations have conducted extensive theoretical and laboratory EOR (enhanced oil recovery) researches, to include validating pilot and field trials relevant to much needed domestic commercial application, while western countries had terminated such endeavours almost completely due to low oil prices. In recent years, oil demand has soared and now these operations have become more desirable. This book is about the recent developments in the area as well as the technology for enhancing oil recovery. The book provides important case studies related to over one hundred EOR pilot and field applications in a variety of oil fields. These case studies focus on practical problems, underlying theoretical and modelling methods, operational parameters (e.g., injected chemical concentration, slug sizes, flooding schemes and well spacing), solutions and sensitivity studies, and performance optimization strategies. The book strikes an ideal balance between theory and practice, and would be invaluable to academicians and oil company practitioners alike.- Updated chemical EOR fundamentals providing clear picture of fundamental concepts- Practical cases with problems and solutions providing practical analogues and experiences- Actual data regarding ranges of operation parameters providing initial design parameters- Step-by-step calculation examples providing practical engineers with convenient procedures

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1.1 Enhanced Oil Recovery’s Potential

- • The industry cannot guarantee new discoveries.

- • New discoveries are most likely to lie in offshore, deep offshore, or difficult-to-produce areas.

- • Producing unconventional resources would be more expensive than producing from existing brown fields by enhanced oil recovery (EOR) methods.

1.2 Definitions of EOR and IOR

1.2.1 Existing Definitions

1.2.2 Proposed Definitions

- • EOR processes

- • Near wellbore conformance control (cement plug/gel treatment for water and gas shutoff)

- • Immiscible gas injection (dry gas, CO2, nitrogen, alternating or co-injection with water)

- • Water injection, cyclic water injection

- • Well stimulation (acidizing and fracturing)

- • Thermal recovery: in situ combustion—forward: dry, wet, ...

Table of contents

- Cover

- Title Page

- Copyright

- Table of Contents

- Preface

- Acknowledgments

- Nomenclature

- Chapter 1: Introduction

- Chapter 2: Transport of Chemicals and Fractional Flow Curve Analysis

- Chapter 3: Salinity Effect and Ion Exchange

- Chapter 4: Mobility Control Requirement in EOR Processes

- Chapter 5: Polymer Flooding

- Chapter 6: Polymer Viscoelastic Behavior and Its Effect on Field Facilities and Operations

- Chapter 7: Surfactant Flooding

- Chapter 8: Optimum Phase Type and Optimum Salinity Profile in Surfactant Flooding

- Chapter 9: Surfactant-Polymer Flooding

- Chapter 10: Alkaline Flooding

- Chapter 11: Alkaline-Polymer Flooding

- Chapter 12: Alkaline-Surfactant Flooding

- Chapter 13: Alkaline-Surfactant-Polymer Flooding

- References

- Index