Brittle Fracture and Damage of Brittle Materials and Composites

Statistical-Probabilistic Approaches

- 296 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Brittle Fracture and Damage of Brittle Materials and Composites

Statistical-Probabilistic Approaches

About this book

Flaws are the principal source of fracture in many materials, whether brittle or ductile, whether nearly homogeneous or composite. They are introduced during either fabrication or surface preparation or during exposure to aggressive environments (e. g. oxidation, shocks). The critical flaws act as stress concentrators and initiate cracks that propagate instantaneously to failure in the absence of crack arrest phenomena as encountered in brittle materials.This book explores those brittle materials susceptible to crack arrest and the flaws which initiate crack induced damage. A detailed description of microstructural features covering numerous brittle materials, including ceramics, glass, concrete, metals, polymers and ceramic fibers to help you develop your knowledge of material fracture.Brittle Failure and Damage of Brittle Materials and Composites outlines the technological progress in this field and the need for reliable systems with high performances to help you advance the development of new structural materials, creating advantages of low density, high resistance to elevated temperatures and aggressive environments, and good mechanical properties.- The effects of flaw populations on fracture strength- The main statistical-probabilistic approaches to brittle fracture- The use of these methods for predictions of failure and effects induced by flaw populations- The application of these methods to component design- The methods of estimation of statistical parameters that define flaw strength distributions- The extension of these approaches to damage and failure of continuous fiber reinforced ceramic matrix composites

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Flaws in Materials

Abstract:

Keywords

1.1 Introduction

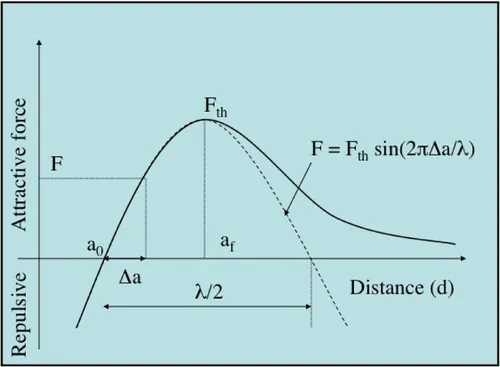

1.2 The theoretical strength and the intrinsic strength of materials

Table of contents

- Cover image

- Title page

- Table of Contents

- Dedication

- Copyright

- Introduction

- 1: Flaws in Materials

- 2: Statistical-Probabilistic Approaches to Brittle Fracture: The Weibull Model

- 3: Statistical-Probabilistic Theories Based on Flaw Size Density

- 4: Statistical-Probabilistic Theories Based on Flaw Strength Density

- 5: Effective Volume or Surface Area

- 6: Size and Stress-state Effects on Fracture Strength

- 7: Determination of Statistical Parameters

- 8: Computation of Failure Probability: Application to Component Design

- 9: Case Studies: Comparison of Failure Predictions Using the Weibull and Multiaxial Elemental Strength Models

- 10: Application of Statistical-Probabilistic Approaches to Damage and Fracture of Composite Materials and Structures

- Bibliography

- Index