eBook - ePub

Multifunctionality of Polymer Composites

Challenges and New Solutions

- 996 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Multi-Functionality of Polymer Composites: Challenges and New Solutions brings together contributions from experts in the field of multifunctionality, presenting state-of-the-art discussion of this exciting and rapidly developing field, thus key enabling technologies for future applications.The text will enable engineers and materials scientists to achieve multifunctionality in their own products using different types of polymer matrices and various nano- and micro-sized fillers and reinforcements, including, but not limited to, carbon nanotubes and graphene. In addition, technologies for the integration of active materials such as shape memory alloys are discussed.The latest developments in a wide range of applications, including automotive/aerospace, electronics, construction, medical engineering, and future trends are discussed, making this book an essential reference for any researcher or engineer hoping to stay ahead of the curve in this high-potential area.

- Provides information on composites and their inherent engineering advantages over traditional materials.

- Presents state-of-the-art information on this exciting and rapidly developing field, enabling engineers and materials scientists to achieve multi-functionality in their own products.

- Includes the latest developments in a wide range of applications, including automotive/aerospace, electronics, construction, and medical engineering.

- An essential reference for any researcher or engineer hoping to stay ahead of the curve in this high-potential area.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Multifunctionality of Polymer Composites by Klaus Friedrich,Ulf Breuer in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

Section III

Applications

Outline

Part I

Transportation

Outline

Chapter 11

Development of multifunctional composites for aerospace application

Xiao-Su Yi, Beijing Institute of Aeronautical Materials (BIAM), Beijing, PR China

Carbon–fiber-reinforced polymer composite structures are widely used in today’s aerospace industries. However, the introduction of the composites in mainframes of modern structures presents special challenges and issues regarding their impact damage resistance due to the brittle nature of the matrix resins and the multifunctional properties (e.g., electrical conductivity) because the composite structures are poor conductors of extreme electrical currents generated by a lightning strike.

For the technological challenge, the first approach, the so-called ex situ toughening technology in the chapter, is associated with the use of amorphous thermoplastic films as interleaves. When an interleaved composite laminate with a thermosetting matrix is cured, highly toughened thin interlaminar regions are established with phase separation and phase inversion. The technology is further developed to meet the challenge of cost-effective liquid moulding by developing preform-based fabrics, the so-called ES™-Fabrics. Improved interlaminar fracture toughnesses, compression after impact (CAI) strength, and balanced in-plane mechanical properties have been achieved.

The second approach is the use of the interleaf material surface coated with conducting silver nanowires (AgNWs). Typical interleaf materials include the thermoplastic films perforated and plastic veils. The AgNWs are deposited on the interleaf surface and even across its thickness; they densely interconnected with each other to form a conductive network like a “spiderweb.” In this way, two interdependent network structures coexist at different scales. On the one hand, the film or veil framework at the micron scale is essential for interleaf toughening, with a substantial improvement in interlaminar fracture toughness, GIC and GIIC. On the other hand, it provides a mechanism for adding nanoscale AgNWs. By incorporating the interleaf materials into the laminated composite system, a nanoscale, 3D cross-linked AgNW network is established throughout the whole composite, providing a clear improvement in electrical conductivity in the transverse and thickness directions of the carbon–fiber composites. The technology is thus called functionalized interlayer technology (FIT). The key advantage of such a technique is that it can significantly and simultaneously increase the impact damage resistance and electrical conductivity of structural composites by selectively interleaving the functionalized interleaf materials.

Keywords

Impact damage resistance; compression after impact; ex situ toughening; liquid moulding; preform-based toughening; ES™-Fabrics; electrical conductivity; interlaminar fracture toughness; functionalized interlayer technology

11.1 Introduction, Motivation, and Technological Challenge

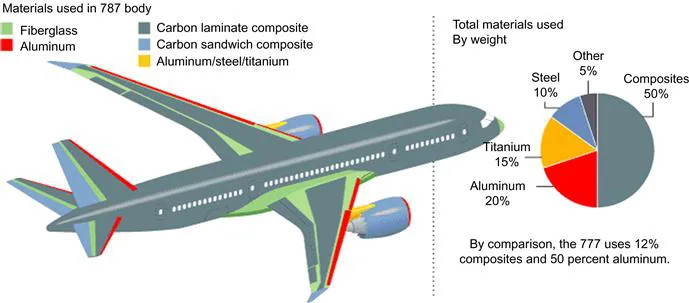

Laminated carbon–fiber-reinforced polymer matrix composites are increasingly used in many industries, particularly in aerospace—e.g., in the design of leading edges, wing skins, helicopters, propeller blades, and engine ducts. Composite materials also begin to feature in primary structures, such as complete wing and fuselage assemblies. A typical example is demonstrated in B 787 Dreamliner (Figure 11.1). However, the design and application of such components or structures in a manner that ensures their safe operation under severe external impact loadings and environmental conditions has been a challenging task. Unlike metallic components, which can yield and dissipate energy via plasticity, composites can only dissipate energy by different damage such as delamination or fracturing processes, which usually degrade the stiffness and strength of the structural component. Therefore, the ability to have high impact damage resistance and tolerance of the composites used in aircraft remains a critical issue in the aerospace industry [1–4].

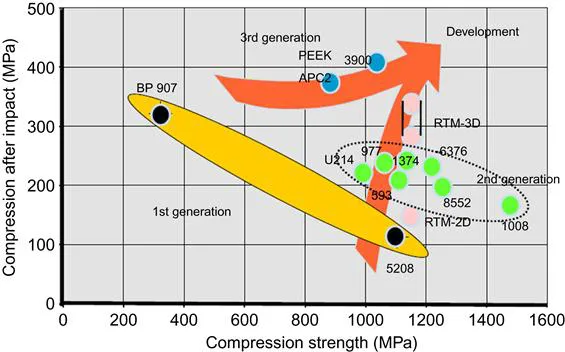

Facing the material challenge in impact damage performance, a roadmap for research and development (R&D) of the aerospace composites was proposed by Airbus (Figure 11.2). In the map, the first generation of composites shows either higher compression strength or compression after impact (CAI) strength. Accompanying the course of advancement of reinforcing carbon fibers, the second generation of composites developed displays higher compression strength in average; however, the CAI property remains apparently unsatisfied. The third generation includes the typical thermoplastic matrix composite like polyetherether ketone (PEEK) and some of the highly toughened epoxy matrix composites, e.g., 3900 (T800H/3900-2 carbon/epoxy composite) in the figure, whose interface contains a discrete thin layer of toughened thermoplastics. However, the thermoplastic composites PEEK generally involve costly manufacturing processes, and the highly toughened epoxy-like 3900 is typically used in the intermediate temperature range. Obviously, aerospace industry looks continuously for composites that have higher compression strength and CAI simultaneously at sufficiently high hot–wet glass transition temperature. For this end, an integrated approach that takes all disciplines into account is necessary.

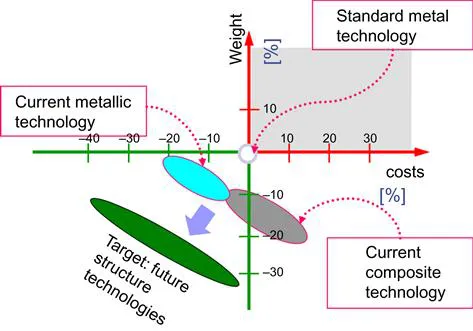

Current state-of-the-art aerospace composites in application are principally prepreg-based. Correspondingly, the autoclave process prevails in this industrial branch. However, a trade-off exists between the performance and affordability for aircraft structures manufactured using prepreg materials and autoclave. The paramount need for the aerospace composites industry can be simply stated as an ongoing search for high-performance materials that can be produced at a low cost. Figure 11.3 shows for example the European vision [5]. Clearly, a 40% cost saving and a 30% weight saving compared to the state-of-the-art cannot be reached by small steps. Improved manufacturing technologies are the primary key to better affordability and quality. It is envisaged that the manufacturing methods will in the near future transfer from autoclave to liquid-molding approaches such as resin transfer molding (RTM), vacuum-assisted RTM (VARTM), and resin film infusion (RFI). To have such processes supplant autoclave manufacturing methods, liquid-molded composites need to have mechanical properties that meet or even exceed those available from the prepregs. Because the fibers used in liquid molding are the same as used in prepregs, mechanical-property improvements must depend on improved matrix resins and preforms. This is obviously a challenging task, particularly for maintaining the equivalent impact damage properties that the state-of-the-art prepreg materials possess.

Having been toughened for higher impact damage properties, however, the aerospace structural composites are difficult to achieve simultaneous multiple functionalities. Among many function-integrations that ar...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- List of Contributors

- Section I: Introduction to Multifunctional Polymer Composites

- Section II: Use of Special Matrices/Reinforcements/Interphases

- Section III: Applications

- Section IV: Smart Materials and Future Trends

- Index