Materials Ageing and Degradation in Light Water Reactors

Mechanisms and Management

- 440 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Materials Ageing and Degradation in Light Water Reactors

Mechanisms and Management

About this book

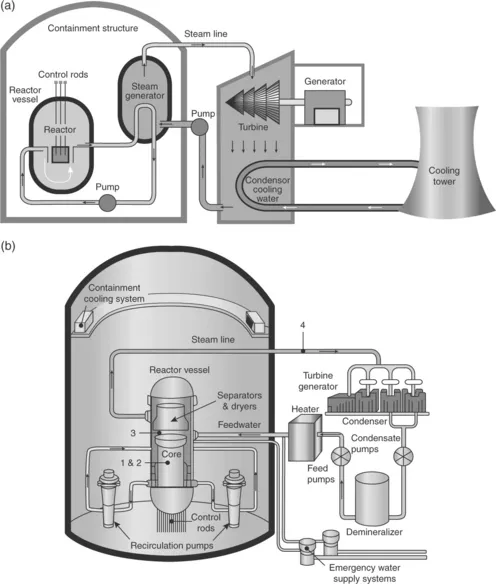

Light water reactors (LWRs) are the predominant class of nuclear power reactors in operation today; however, ageing and degradation can influence both their performance and lifetime. Knowledge of these factors is therefore critical to safe, continuous operation. Materials ageing and degradation in light water reactors provides a comprehensive guide to prevalent deterioration mechanisms, and the approaches used to handle their effects.Part one introduces fundamental ageing issues and degradation mechanisms. Beginning with an overview of ageing and degradation issues in LWRs, the book goes on to discuss corrosion in pressurized water reactors and creep deformation of materials in LWRs. Part two then considers materials' ageing and degradation in specific LWR components. Applications of zirconium alloys in LWRs are discussed, along with the ageing of electric cables. Materials management strategies for LWRs are then the focus of part three. Materials management strategies for pressurized water reactors and VVER reactors are considered before the book concludes with a discussion of materials-related problems faced by LWR operators and corresponding research needs.With its distinguished editor and international team of expert contributors, Materials ageing and degradation in light water reactors is an authoritative review for anyone requiring an understanding of the performance and durability of this type of nuclear power plant, including plant operators and managers, nuclear metallurgists, governmental and regulatory safety bodies, and researchers, scientists and academics working in this area.- Introduces the fundamental ageing issues and degradation mechanisms associated with this class of nuclear power reactors- Considers materials ageing and degradation in specific light water reactor components, including properties, performance and inspection- Chapters also focus on material management strategies

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Overview of ageing and degradation issues in light water reactors (LWRs)

1.1 Introduction

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Energy

- Foreword

- Preface

- Chapter 1: Overview of ageing and degradation issues in light water reactors (LWRs)

- Chapter 2: Corrosion in pressurized water reactors (PWRs)

- Chapter 3: Creep deformation of materials in light water reactors (LWRs)

- Chapter 4: Properties of zirconium alloys and their applications in light water reactors (LWRs)

- Chapter 5: Performance and inspection of zirconium alloy fuel bundle components in light water reactors (LWRs)

- Chapter 6: Ageing of electric cables in light water reactors (LWRs)

- Chapter 7: Materials management strategies for pressurized water reactors (PWRs)

- Chapter 8: Materials management strategies for VVER reactors

- Chapter 9: Materials-related problems faced by light water reactor (LWR) operators and corresponding research needs

- Index