1.1 Introduction

The core content of this edition is essentially the same as the first, but the opportunity has now been taken to update the coverage of both materials and associated manufacturing advances and generally report on progress made during the last decade. The latest legislative and environmental requirements are highlighted and the response of the industry in terms of design and processing are outlined. These include the progress made with regard to higher strength steels, the application of composites, aluminum and other lightweight materials. Advances in processing include the automation of composite outer panel production to a mass production stage, essential if composites are to reach volume models, and the increasing use of lasers in joining, which has been enabled by the increasing versatility of beam technology offered by innovative power sources and transmission modes, such as YAG systems. The emergence of electrical drive systems and their possible effects on body-in-white (BIW) design and materials choice is also considered, although it may be at least a decade before electric vehicle (EV) systems in various guises have a real presence in the market. In the meantime the opportunity exists for the full potential of alternative steels and lightweight materials being developed through current programs to be realized.

Significant additions to relevant chapters have been made on subjects such as the development of lightweight body materials in North America and lessons learned from the Far East with regard to the implementation of new steel grades. In particular, the contribution from the FreedomCAR Automotive Lightweighting Materials program, sponsored by the US Department of Energy, is discussed. This program illustrates the considerable investment in terms of resources and efforts being made into the research and development of lightweight materials. A major thrust is being made there to reduce the cost of carbon fiber, so that it becomes a competitive option as a material choice for body structure, and practical recycling solutions are being explored. The increased application of non-ferrous body content is being studied, especially with regard to magnesium. The EV influenced ‘Future Steel Vehicle’ project is also outlined; it looks at possible structures for small and larger cars from hybrid through to fuel cell modes and considers the modifications necessary for battery and cell stacks. The importance of this work is its emphasis on volume production and the pragmatic changes required in order for newer materials to be handled in volume, and, thus, achieve worthwhile reductions in greenhouse and other harmful emissions. The opportunity is also taken to update readers on the latest targets for emissions, recycling and end-of-life vehicle (ELV) legislation and the recent progress that has been made by manufacturers in addressing them.

A major objective for BIW development remains its contribution to emissions control through weight reduction, which is achieved by design and materials choice, and complements the work being carried out on alternative power modes. Significant reductions have been achieved in current structures, but further reductions will be necessary to offset the heavier batteries or cell stacks of future designs. Steady progress is reported in the use of hydrogen, used either as a replacement fuel in conventional engines or within fuel cells, together with the different types of ‘electromobility’ referred to above.

Events in the last decade have underlined the critical status of oil supplies. The strategic importance of oil has been highlighted by recent events in the Middle East, while in the Gulf of Mexico hurricane damage to significant oil installations and has further heightened our awareness of oil dependence. Some reports suggest that existing reserves of oil could run out in 10 years, although 40 years is generally thought to be more realistic. Other events have emphasized the danger to the environment by mismanagement of these oil resources.

The interest in alternative fuels is, therefore, intense. Hybrid electric vehicles (HEV) now have plug-in derivatives (PHEV); battery electric vehicles (BEV) have been developed as city cars, while small internal combustion engines (ICE) supplement electrical systems in extended range vehicles (EREV). Fuel cell systems (FCEV) are now undergoing extended fleet trials. Serious programs are working on the provision of a universal infrastructure for the supply of hydrogen and plug-in fast-recharging stations for next generation electric vehicles. The effects of these systems and the differences in material requirements and architecture compared with ICE-propelled vehicles are considered. The current range of steels will continue to be used in the medium term, as safety issues are addressed with increasingly sophisticated front, side and rear end designs, together with aluminum and magnesium to maximize weight reduction. The development of plastics and composites in body design is further prompted by their good performance in pedestrian impact situations, and this is driving the search for effective recycling solutions for these materials.

The basic format and content of the book still stands as before, as does the sequence of the chapters, which offers the most logical form of presentation. It is inevitable that during the course of this book’s preparation some examples will have become outmoded due to constant model changes. This is likely to be evident to some extent in Chapter 2 on design. However, the design principles and design logic referred to remain unchanged. Publications have recently emerged on the subject of lightweight automotive design, but these have tended to concentrate on the more esoteric materials that, as yet, have only limited application, chiefly in prestige, emerging EV and performance vehicles. While it is important to understand these technologies for the future, the emphasis within the industry is on restoring the economic ‘health’ of the major car companies by making steady improvements in the efficiency of existing volume production processes. This means that there is a focus on known and proven specifications as well as the application of newer lightweight variants. This book reflects this trend within the industry. Therefore, it explores the realistic options for materials choices in relation to meeting future challenges, with special emphasis on manufacturing issues in volume production.

The overwhelming choice for the majority of volume car designs is still steel for reasons of cost, safety, mass manufacturability and universal repair. However, the structure is becoming more and more hybridized with regard to materials, to meet emissions and safety regulations, and in the case of electric vehicles to offset weight and increase range. The logic behind the choice of body materials over recent years provides a fascinating story when considered in the context of overall vehicle development. In the 1970s, corrosion resistance was the main factor influencing the choice of body material. This gradually changed to weight reduction with the introduction of CAFE fuel economy requirements in the 1980s. Body weight has been reduced through the development and implementation of high-strength steels, which have offered down-gauging possibilities and greater energy absorption, and to a lesser extent through the use of aluminum. These materials in various forms have been increasingly utilized to satisfy safety standards in the form of new car assessment program (NCAP) requirements. As CO2 emissions have gradually dropped for ICE power units and the development of electromobility moves these towards zero, the emphasis within the overall architecture is changing from mainly upper body design, where significant weight savings and safety improvements have been achieved, to now include lower structural design, to offset the considerable extra weight of battery and cell stack power units and added impact resistance to protect the critical electrics fore and aft. These influences are explored in Chapter 9, which now also includes the effects of geography and vehicle population (‘vehicle demographics’) on the selection criteria and availability of an increasingly sophisticated range of materials.

1.3 Materials overview

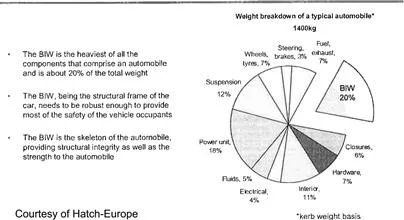

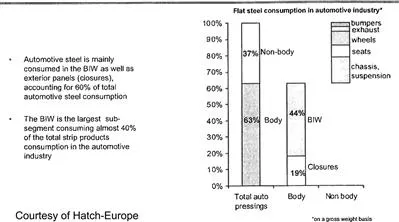

Before considering BIW material aspects in detail it is useful to introduce the significance of the body structure in terms of the overall vehicle make-up of the average mass produced car (see Figure 1.1). Flat strip products comprise a major part of the vehicle structure, and using steel as an example its application is shown in Figure 1.2, the body comprising the largest segment.

FIGURE 1.1 Contribution of body-in-white to overall vehicle weight

FIGURE 1.2 Sheet steel content/form within the overall vehicle construction of a typical family car

The bodywork conveys the essential identity and aesthetic appeal of the vehicle, ranging from the styling panache of Aston Martin or Ferrari to the drab functionality of utility vehicles such as the Trabant. However, the actual material from which a vehicle body is fabricated has, until recently, attracted relatively little interest. Nevertheless, of all the components comprising the vehicle, the skin and underlying structural framework provide some of the most interesting advances in materials and associated process technology. This is reflected in the many changes that have taken place in the body materials used for automotive body structures over 100 years of production. The initial change was the replacement of the largely handcrafted bodies constructed of sheet metal, fabric and timber with sheet steel during the 1920s. Low...