- 306 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

PEEK Biomaterials Handbook

About this book

PEEK biomaterials are currently used in thousands of spinal fusion patients around the world every year. Durability, biocompatibility and excellent resistance to aggressive sterilization procedures make PEEK a polymer of choice, replacing metal in orthopedic implants, from spinal implants and hip replacements to finger joints and dental implants.This Handbook brings together experts in many different facets related to PEEK clinical performance as well as in the areas of materials science, tribology, and biology to provide a complete reference for specialists in the field of plastics, biomaterials, medical device design and surgical applications.Steven Kurtz, author of the well respected UHMWPE Biomaterials Handbook and Director of the Implant Research Center at Drexel University, has developed a one-stop reference covering the processing and blending of PEEK, its properties and biotribology, and the expanding range of medical implants using PEEK: spinal implants, hip and knee replacement, etc.- Covering materials science, tribology and applications- Provides a complete reference for specialists in the field of plastics, biomaterials, biomedical engineering and medical device design and surgical applications

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Steven M. Kurtz, Ph.D.

1.1. Introduction

1.2. What Is a Polymer?

|

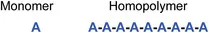

| Figure 1.1 Schematic representation of a homopolymer. |

|

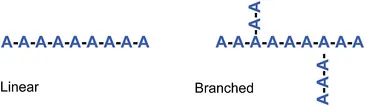

| Figure 1.2 Schematic representation of linear and branched homopolymers. |

1.3. What Is PEEK?

Table of contents

- Cover image

- Table of Contents

- Dedication

- Front Matter

- Copyright

- Foreword

- List of Contributors

- Chapter 1. An Overview of PEEK Biomaterials

- Chapter 2. Synthesis and Processing of PEEK for Surgical Implants

- Chapter 3. Compounds and Composite Materials

- Chapter 4. Morphology and Crystalline Architecture of Polyaryletherketones

- Chapter 5. Fracture, Fatigue, and Notch Behavior of PEEK

- Chapter 6. Chemical and Radiation Stability of PEEK

- Chapter 7. Biocompatibility of Polyaryletheretherketone Polymers

- Chapter 8. Bacterial Interactions with Polyaryletheretherketone

- Chapter 9. Thermal Plasma Spray Deposition of Titanium and Hydroxyapatite on Polyaryletheretherketone Implants

- Chapter 10. Surface Modification Techniques of Polyetheretherketone, Including Plasma Surface Treatment

- Chapter 11. Bioactive Polyaryletherketone Composites

- Chapter 12. Porosity in Polyaryletheretherketone

- Chapter 13. Applications of Polyaryletheretherketone in Spinal Implants

- Chapter 14. Isoelastic Polyaryletheretherketone Implants for Total Joint Replacement

- Chapter 15. Applications of Polyetheretherketone in Trauma, Arthroscopy, and Cranial Defect Repair

- Chapter 16. Arthroplasty Bearing Surfaces

- Chapter 17. FDA Regulation of Polyaryletheretherketone Implants

- Index