- 784 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Textiles for Protection

About this book

In today's climate there is an increasing requirement for protective textiles, whether for personal protection, protection against the elements, chemical, nuclear or ballistic attack. This comprehensive book brings together the leading protective textiles experts from around the world. It covers a wide variety of themes from materials and design, through protection against specific hazards, to specific applications. This is the first book of its kind to give a complete coverage of textiles for protection.

- Covers a wide variety of themes from materials and design, through protection against specific hazards, to specific applications

- The first book of its kind to give a complete coverage of textiles for protection

- Written by leading protective textiles experts from around the world

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Overview of protective clothing

W ZHOU, N REDDY and Y YANG, University of Nebraska – Lincoln, USA

Publisher Summary

The technological developments have exposed people to greater risks and danger of being affected by unknown physical, chemical, and biological attacks. One such currently relevant danger is from bioterrorism and weapons of mass destruction. One continues to be exposed to hazards from fire, chemicals, radiation, and biological organisms such as bacteria and viruses. Fortunately, simple and effective means of protection from most of these hazards are available. Textiles are an integral part of most protective equipment. Protective clothing is manufactured using traditional textile manufacturing technologies such as weaving, knitting, and non-wovens and also by specialized techniques such as 3D weaving and braiding using natural and man-made fibers. Protective clothing is now a major part of textiles classified as technical or industrial textiles. Protective clothing refers to garments and other fabric-related items designed to protect the wearer from harsh environmental effects that may result in injuries or death. Depending on the end use, personal protective textiles can be classified as industrial protective textiles, agricultural protective textiles, military protective textiles, civilian protective textiles, medical protective textiles, sports protective textiles, and space protective textiles.

1.1 Introduction

Scientific advancements made in various fields have undoubtedly increased the quality and value of human life. It should however be recognized that the technological developments have also exposed us to greater risks and danger of being affected by unknown physical, chemical and biological attacks. One such currently relevant danger is from bioterrorism and weapons of mass destruction. In addition, we continue to be exposed to hazards from fire, chemicals, radiation and biological organisms such as bacteria and viruses. Fortunately, simple and effective means of protection from most of these hazards are available. Textiles are an integral part of most protective equipment. Protective clothing is manufactured using traditional textile manufacturing technologies such as weaving, knitting and non-wovens and also by specialized techniques such as 3D weaving and braiding using natural and man-made fibers.

Protective clothing is now a major part of textiles classified as technical or industrial textiles. Protective clothing refers to garments and other fabric-related items designed to protect the wearer from harsh environmental effects that may result in injuries or death (Adanur, 1995). Today, the hazards that we are exposed to are often so specialized that no single type of clothing will be adequate for protection. Extensive research is being done to develop protective clothing for various regular and specialized civilian and military occupations (Adanur, 1995; Bajaj et al., 1992; Holmes, 2000). Providing protection for the common population has also been taken seriously considering the anticipated disaster due to terrorism or biochemical attacks (Holmes, 2000; Koscheyev and Leon, 1997).

1.2 Market prospects

Protective textiles are a part of technical textiles that are defined as comprising all those textile-based products which are used principally for their performance or functional characteristics rather than their aesthetic or decorative characteristics (Byrne, 2000). In 2000, technical textiles accounted for about 25% of all textile consumption by weight (David Rigby Associates, 2004). Protective textiles account for 1.4% of the total technical textiles with an estimated value of US$5.2 billion.

Consumption of protective clothing has increased linearly in the last ten years, and in 2010 it is expected that about 340,000 tons of protective clothing will be consumed, an increase of 85% over consumption in 1995. The Americas (mainly USA and Canada) have the highest consumption of protective clothing per annum at about 91 300 tons followed by Europe with 78,200 tons and Asia with 61,300 tons (David Rigby Associates, 2004). All other regions consume only 7,200 tons, 3.0% of total protective textile consumption.

1.3 Classification

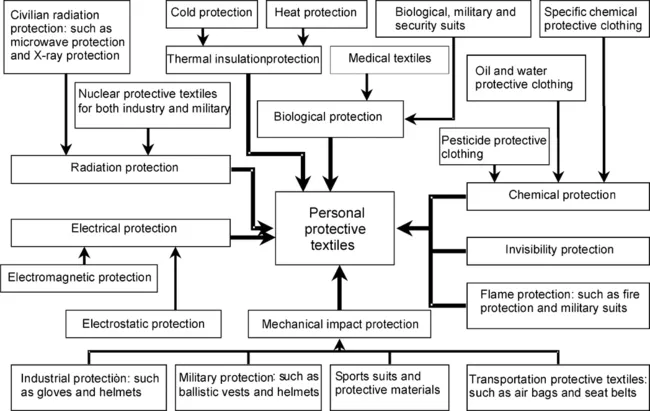

Classifying personal protective textiles is complicated because no single classification can clearly summarize all kinds of protection. Overlap of the definitions is common since there are so many occupations and applications that even the same class of protective clothing often has different requirements in technique and protection. Depending on the end use, personal protective textiles can be classified as industrial protective textiles, agricultural protective textiles, military protective textiles, civilian protective textiles, medical protective textiles, sports protective textiles and space protective textiles.

Personal protective textiles can be further classified according to the end-use functions such as thermal (cold) protection, flame protection, chemical protection, mechanical impact protection, radiation protection, biological protection, electrical protection and wearer visibility. Their relationship is illustrated in Fig. 1.1. Unless indicated otherwise, this classification will be used in the following descriptions.

1.3.1 Fire protection

It would have been impossible for humans to survive the primitive age without the use of fire. However, fire could be dangerous. Fire disasters occur frequently resulting in non-fatal and fatal casualties. Of all the accidental fires in dwellings, occupied buildings and outdoor fires, the great majority (79% of the total in 1986) of deaths resulted from fires in dwellings although only 16% of fires happened in dwellings (Bajaj et al., 1992). The most frequently ignited materials were the textiles, especially upholstery and furnishings (Bajaj et al., 1992). It should, however, be noted that the main cause of death in a fire accident is not direct burning but suffocation due to the smoke and toxic gases released during burning. In the UK, 50% of fatalities in fire accidents were directly attributable to this cause (Bajaj et al., 1992). Therefore, the use of non- or low-toxic burning materials is very important for fire protection.

Human tissue (skin) is very sensitive to heat. It is reported that, at 45 °C, the sensation of pain is experienced, and at 72 °C the skin is completely burnt (Bajaj et al., 1992; Panek, 1982). The purpose of fire-protective clothing is to reduce the rate of heating of human skin in order to provide the wearer enough time to react and escape. The time that a wearer stays in flame circumstances and the amount of heat flux produced are important factors for designing the protective stratagem. Under normal conditions, only 3–10 seconds are available for a person to escape from a place of fire with a heat flux of about 130–330 kW/m2 (Holmes, 2000). Fibers commonly used for textiles are easily burnt. Untreated cotton will either burn (flaming combustion) or smolder (smolder combustion), whenever it is in the presence of oxygen and the temperature is high enough to initiate combustion (360–420 °C) (Wakelyn, 1997).

Protective clothing designed for flame protection must have two functions, i.e., be flame-resistant and form a heat barrier. The latter is a v...

Table of contents

- Cover image

- Title page

- Table of Contents

- Related titles

- Copyright

- Contributor contact details

- Introduction

- Chapter 1: Overview of protective clothing

- Chapter 2: Standards for protective textiles

- Chapter 3: Fashion and function – factors affecting the design and use of protective clothing

- Chapter 4: Steps in the selection of protective clothing materials

- Chapter 5: Fibres and fabrics for protective textiles

- Chapter 6: Technical textiles for protection

- Chapter 7: Intelligent textiles for protection

- Chapter 8: Surface treatments for protective textiles

- Chapter 9: Evaluation of protective clothing systems using manikins

- Chapter 10: Interactions between protection and thermal comfort

- Chapter 11: Modeling thermal burn injury protection

- Chapter 12: Civilian protection and protection of industrial workers from chemicals

- Chapter 13: Textiles for UV protection

- Chapter 14: Textiles for protection against cold

- Chapter 15: Thermal (heat and fire) protection

- Chapter 16: Microorganism protection

- Chapter 17: Textiles for respiratory protection

- Chapter 18: Electrostatic protection

- Chapter 19: Ballistic protection

- Chapter 20: Chemical and biological protection

- Chapter 21: Military protection

- Chapter 22: Firefighters’ protective clothing

- Chapter 23: Protection against knives and other weapons

- Chapter 24: Flight suits for military aviators

- Chapter 25: Protection for workers in the oil and gas industries

- Chapter 26: Motorcyclists

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Textiles for Protection by Richard A. Scott in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.