- 260 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

With increased environmental awareness and rising costs, manufacturers are investing in real time monitoring and control of dyeing to increase its efficiency and quality. This book reviews ways of automating the dyeing process as well as ways of understanding key processes in dyeing, including dye transport in fluid systems. This understanding is then used to create models to simulate the dyeing process which can then be used to develop appropriate measurement and control systems. Control of variables such as temperature, pH, conductivity and dye concentration can then be used to ensure a more consistent and cost-effective dyeing process.

- Reviews the dyeing process and dye house automation, and the factors that affect dyeing quality and common difficulties in the process.

- Explains the principles underlying the dyeing process and provides a thorough understanding of the mathematical models that can be used to approximate it.

- Discusses techniques for monitoring dyebaths and controlling the dyeing process.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Modelling, Simulation and Control of the Dyeing Process by R. Shamey,X. Zhao in PDF and/or ePUB format, as well as other popular books in Computer Science & Computer Science General. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction to dyeing and dyehouse automation

Abstract:

This chapter introduces the concept of textile dyeing, based on a brief review of various types of dyes and fibres and the interaction between dyes and fibres, and the mode of controlling dyeing processes based on conventional time-temperature profiles as well as those based on controlling the rate of dye exhaustion. The package dyeing process and parameters influencing the adsorption and diffusion of dyes within packages are then introduced. Various adsorption isotherms are briefly examined and factors that affect the dyeing of fibres are discussed. Different control strategies based on assessing the amount of dye in the dyebath are then briefly examined.

Key words

dyeing; dyes; textile fibres; dyeing quality; dyeing rate; levelness; dyeing vessels; package dyeing; dyeing automation; exhaustion profiles

1.1 Introduction

Dyeing is a very complicated process with many different phenomena occurring simultaneously. It covers different areas of science including chemistry, physics, mechanics, physical chemistry, fluid mechanics, thermodynamics and others.1 Devising the most efficient dyeing process typically involves the following concerns: machinery design, pre-selection of dyes of compatible properties, use of pH versus time profiles, selection of liquor ratio, flow rate and flow direction reversal times, and design of temperature versus time profiles.2

1.1.1 Textile fibres

A fibre is characterised by its high ratio of length to thickness, and by its strength and flexibility. Fibres may be of natural origin, or formed from natural or synthetic polymers. They are available in a variety of forms. Staple fibres are short, with length-to-thickness ratios around 103 to 104, whereas this ratio for continuous filaments is at least several million.3 The form and properties of a natural fibre such as cotton are fixed, but for artificially made fibres a wide choice of properties is available by design. The many variations include staple fibres of any length, single continuous filaments (monofilaments), or yarns constituted of many filaments (multi-filaments). The fibres or filaments may be lustrous, dull or semi-dull, coarse, fine or ultra-fine, circular or of any other cross-section, straight or crimped, regular or chemically modified, and solid or hollow.

Natural fibres have a number of inherent disadvantages. They exhibit large variations in staple length, fineness, shape, crimp and other physical properties, depending upon the location and conditions of growth. Animal and vegetable fibres also contain considerable and variable amounts of impurities, whose removal before dyeing is essential, and entails much processing. Artificially made fibres are much more uniform in their physical characteristics. Their only contaminants are small amounts of slightly soluble low molecular weight polymer and some surface lubricants and other chemicals added to facilitate processing. These are relatively easy to remove compared with the difficulty of purifying natural fibres.4

Water absorption is one of the key properties of a textile fibre. Protein or cellulosic fibres are hydrophilic and absorb large amounts of water, which causes radial swelling. Hydrophobic synthetic fibres such as polyester, however, absorb almost no water and do not swell. The hydrophilic or hydrophobic character of a fibre influences the types of dyes that it will absorb.5 The ability to be dyed to a wide range of hues and depths is a key requirement for almost all textile materials.

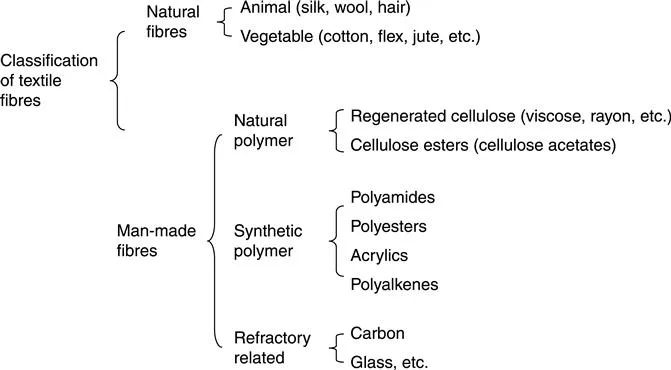

An important property of a textile fibre is its regain, which is the weight of water absorbed per unit weight of completely dry fibre, when it is in equilibrium with the surrounding air, at a given temperature and relative humidity. The regain increases with increase in the relative humidity but diminishes with increase in the air temperature. Water absorption by a fibre liberates heat (exothermic) and will therefore be less favourable at higher temperatures. The heat released is often a consequence of the formation of hydrogen bonds between water molecules and appropriate groups in the fibre.6 When the final regain is approached by drying wet, swollen fibres, rather than by water absorption by dry fibres, the regain is higher. The fibres at present available may be classified as shown in Fig. 1.1.

For hydrophilic fibres such as wool, cotton and viscose, the relatively high regain values significantly influence the gross weight of a given amount of fibre. This is significant in dyeing. Amounts of dyes used are usually expressed as a percentage of the weight of material to be coloured. Thus, a 1.0% dyeing corresponds to 1.0 g of dye for every 100 g of fibre, usually weighed under ambient conditions. For hydrophilic fibres, the variation of fibre weight with varying atmospheric conditions is therefore an important factor influencing colour reproducibility in repeat dyeings.

1.1.2 Dyes

A dye is a substance capable of imparting its colour to a given substrate, such as wool. A dye must be soluble in the application medium, usually water, at some point during the coloration process. It must also exhibit some substantivity for the material being dyed and be absorbed from the aqueous solution.7

For diffusion into a fibre, dyes must be present in the water in the form of individual molecules. These are often coloured anions; for example, sodium salts of sulphonic acids. They may also be cations such as Mauveine, or neutral molecules with slight solubility in water, such as disperse dyes. The dye must have some attraction for the fibre under the dyeing conditions so that the solution gradually becomes depleted. In dyeing terminology, the dye has substantivity for the fibre and the dyebath becomes exhausted.8

The four major characteristics of dyes are:

• intense colour

• solubility in water at some point during the dyeing cycle

• substantivity for the fibre being dyed

• reasonable fastness properties of the dyeing produced.

The structures of dye molecules are complex in comparison with those of most common organic compounds. Despite their complexity, dye structures have a number of common features. Most dye molecules contain a number of aromatic rings, such as those of benzene or naphthalene, linked in a fully conjugated system. This means that there is a long sequence of alternating single and double bonds between the carbon and other atoms throughout most of the structure. This type of arrangement is often called the chromophore or colour-donating unit. The conjugated system allows extensive delocalisation of the π electrons from the double bonds and results in smaller differences in energy between the occupied and unoccupied molecular orbitals for these electrons. At least five or six conjugated double bonds are required in the molecular structure for a compound to be coloured.9

Table 1.1 shows partial classifications of dyes as presented in the Colour Index. In order to gain an optimum result, the appropriate dye class for the fibre must be used, along with specific dyeing conditions. The ten major dye classes involve acid, metal complex, mordant, direct, vat, sulphur, reactive, basic, disperse and azoic dyes. Some of the ten major dye classes shown in Table 1.1 can be used to dye the same fibre type, but varying conditions are required. For example, acid, metal complex, mordant and reactive dyes can all be used to dye wool. However, there may be one type of dye that is preferred for a certain dyeing process, for example, disperse dyes for polyester fibres.

Table 1.1

Classification of dyes according to chemical constitution and usage

| Classification of dyes according to chemical constitution | Classification of dyes according to textile usage |

| Azo dyes | Acid dyes |

| Anthraquinone dyes | Azoic dyes |

| Heterocyclic dyes | Basic dyes |

| Indigoid dyes | Direct dyes |

| Nitro dyes | Disperse dyes |

| Phthalocyanine dyes | Mordant dyes |

| Polymethine dyes | Pigment |

| Stilbene dyes | Reactive dyes |

| Sulphur dyes | Sulphur dyes |

| Triphenylmethane | Vat dyes |

There are numerous factors involved in the selection of dyes for colouring textile materials in a particular shade.10 Some of these are:

• the type of fibres to be dyed

• the form of the textile material and the degree of levelness required – level dyeing is less critical for loose fibres, which are subsequently blended, than it is for fabric

• the fastness propert...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication I

- Dedication II

- Woodhead Publishing Series in Textiles

- Preface

- Definition of terms

- Nomenclature

- 1. Introduction to dyeing and dyehouse automation

- 2. Principles underlying the dyeing process

- 3. Dye transport in fluid systems

- 4. Developing theoretical models of dyeing

- 5. Solving dynamic equations in dye transport

- 6. Simulation of the dyeing process

- 7. Principles of control in dyeing processes

- 8. Measurement and control of dyeing

- Index