eBook - ePub

Adhesives Technology for Electronic Applications

Materials, Processing, Reliability

- 475 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Adhesives Technology for Electronic Applications

Materials, Processing, Reliability

About this book

This book is unique in its comprehensive coverage of all aspects of adhesive technology for microelectronic devices and packaging, from theory to bonding to test procedures. In addition to general applications, such as dies, substrate, and lid and chip stack attachments, the book includes new developments in anisotropic, electrically conductive, and underfill adhesives. Rapid curing methods such as UV, microwave, and moisture (which comply with current environmental and energy requirements) are covered. Over 80 tables and 120 figures provide a wealth of data on properties, performance, and reliability. Also included are examples of commercially available adhesives, suppliers, and equipment. Each chapter provides comprehensive references.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

Adhesives are extensively used and are vital in the assembly and packaging of electronic devices, especially in the current proliferation and mass production of electronic hardware. Adhesives are used in assembling semiconductor die, both in single-chip packages and in multichip assemblies. Both bare-chip devices and prepackaged components are attached and electrically connected with adhesives to produce electronic circuits such as printed-wiring assemblies (PWAs), thin- and thick-film hybrid microcircuits, and multichip modules. Adhesives, as pastes or as solid films, are also used in fabricating high-density multilayer interconnect substrates, flexible circuits, flat-panel displays, and a host of other emerging applications including optoelectronics; high-speed, high-frequency circuits; sensors; and smart cards. Due to their low cost, ease of rework, and low processing temperatures, polymer adhesives have replaced many traditional interconnect materials such as solder, eutectic alloys, and wire, especially for most commercial and consumer electronics. However, because of the large number of adhesives available and the variety of polymer types, forms, and formulations, a basic understanding of adhesives and their properties is necessary in their selection and application to assure performance and avoid subsequent reliability problems. The prime objective of this book is to provide this basic understanding and define guidelines for selecting and qualifying adhesives based on the product and the conditions the adhesive is expected to meet.

1.1 ADHESIVE TYPES AND DEFINITIONS

Adhesives used in assembling electronic circuits may be classified based on their physical form, polymer type, molecular structure, formulation, curing method, function, or intended application.

1.1.1 Classification by Form

First, in terms of their physical form, adhesives may be either pastes or preforms (also known as films or tapes). Pastes are semisolid materials, easily dispensed through a needle or applied by screen or stencil printing. Film adhesives are solid sheets of thermoplastic or partially cured (B-staged) thermosetting polymers that can be cut to size and generally used to attach large-area components, substrates, and lids.

Paste adhesives, in turn, may be single-component or two-component types. A single-component adhesive is a one-part system in which the hardener or catalyst is latent, that is, although mixed with the resin portion, it will not react until a certain cure temperature has been reached. A two-component system consists of a separate resin portion, referred to as Part A, and a hardener or catalyst portion, Part B, either of which may contain filler. The two parts are packaged and stored in separate containers. When ready for use, the two parts are weighed, mixed, deaerated, dispensed, and cured. Two-part adhesives may be converted to one-part systems by quickly mixing Parts A and B, deaerating, freezing, and then storing the mixture at temperatures of −40°C or lower. These one-part adhesives, known in the trade as frozen adhesives, may be purchased from several suppliers in tubes or syringes of various sizes and amounts. Frozen adhesives are generally epoxies and are highly desirable from a manufacturing standpoint since the electronics assembler obviates the risk of human errors inherent in the weighing, mixing, and processing of small batches of adhesive.

1.1.2 Classification by Polymer or Chemical Type

Adhesives are often referred to by their polymer type. The major polymer types used in electronics packaging are epoxies, silicones, acrylics, polyurethanes, polyimides, and cyanate esters. Some generic properties apply to each type but, in generalizing, one must be careful since there are hundreds of formulations of each type on the market, each with minor or major differences in properties. Even for a specific formulation, an adhesive’s processing conditions, such as its cure schedule, can affect the final properties. Chapter 3 provides a discussion of the major polymer types and their properties.

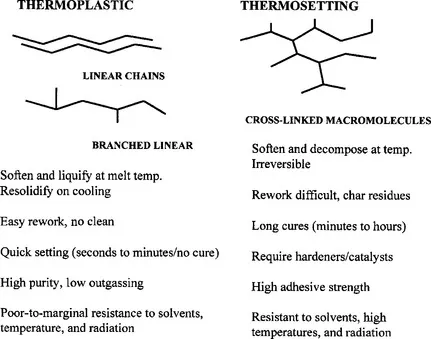

Polymer adhesives may be further classified as either thermoplastic or thermosetting, depending on whether their molecular structures after curing are linear or crosslinked. The linear polymers may be straight chains or branched chains (Fig. 1.1). Thermoplastic adhesives melt and flow at a specific temperature or within a narrow temperature range, then quickly resolidify on cooling. Thermoplastic adhesives are sometimes called hot-melt adhesives and are particularly advantageous in their ease of processing and reworking. Most polyurethanes and polyamides fall in this category. Although thermoplastic polymers are linear, not all linear polymers behave as thermoplastics. Many linear polymers have a high aromatic or heterocyclic content in their structures, thus increasing their thermal stabilities to a temperature that, instead of melting, char and decompose like thermosetting polymers. Among these are polyimide pastes. Other thermoplastic film adhesives that are fully polymerized, high molecular-weight resins behave in the same way; examples are polyetheretherketone (PEEK®, a trademark of Victrex), polyetherimide (ULTEM®, a trademark of General Electric), fluorinated ethylene propylene (FEP), polysiloxane imide, and some epoxies.

Figure 1.1 Representations of thermoplastic and thermosetting polymer structures.

Thermosetting adhesives, on the other hand, soften as the temperature is increased to the glass transition temperature, but do not melt and resolidify. Instead, because of their highly cross-linked macrostructures, they decompose and char on reaching their decomposition temperatures. Epoxies, cyanate esters, and phenolics are generally thermosetting types.

A unique adhesive type is silver-glass; a paste consisting of a glass matrix blended with silver particles, a polymer binder, and a solvent. Silver-glass adhesives are not polymer types. Although a polymer resin is added to the formulation to give the paste the thixotropic properties needed during dispensing or screen printing, the resin is subsequently burned off during final processing. Silver-glass adhesives are processed at much higher temperatures (400°C-450°C) than either polymer adhesives (75°C-175°C) or solders (180°C–300°C). These high temperatures are required to burn-off the polymer binder, melt the glass, and fuse the glass and oxides.[1]

1.1.3 Classification by Formulation

In many adhesives formulations, the resin portion is the same or similar and what determines its properties is the hardener or catalyst that is used to cure the resin. Thus, depending on the hardener, epoxy adhesives may be referred to as amine-cured, anhydride-cured, polyamide-cured, or novolac-cured. Polyurethanes may be polyol-cured or hydroxypol...

Table of contents

- Cover

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface

- Acknowledgements

- Chapter 1: Introduction

- Chapter 2: Functions and Theory of Adhesives

- Chapter 3: Chemistry, Formulation, and Properties of Adhesives

- Chapter 4: Adhesive Bonding Processes

- Chapter 5: Applications

- Chapter 6: Reliability

- Chapter 7: Test and Inspection Methods

- Appendix

- Index

- MATERIALS AND PROCESSES FOR ELECTRONIC APPLICATIONS SERIES

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Adhesives Technology for Electronic Applications by James J. Licari,Dale W. Swanson in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.