![]()

1 Polymeric Materials and Properties

There are large differences among the testing methods, significance, interpretation and usage of the properties, processing methods, and applications of materials manufactured by different industries. There is not a single material that is suitable for use for all applications. Each new property developed for each material opens the doors for new applications, technologies, and innovations that will improve the efficiency and quality of life of the end users.

Product designers cannot expect equivalent properties for the families of materials (steels, thermoplastics, aluminum alloys, rubber), because each material family has unique properties developed for specific applications and market needs. In addition, these materials are processed using different manufacturing processes and quality control methods. All materials have advantages and disadvantages (properties, processes, and quality), making it difficult to compare the cost of finished products made of different materials and by different processes.

The selection of materials is directly related to the end-use applications, whether or not one material’s performance is better than another. To illustrate this point, a thermoplastic material cannot replace a structural steel beam used in building construction. The thermoplastic resins do not have the required mechanical strength, creep resistance, or sufficient melt flow to be extruded into thick walled shapes. The thermoplastic beams would be expected to warp under the load of a building structure. However, structural beams can be made of thermoset composite plastics, although these composite materials are costlier than metals. In less demanding applications in the housing industry, wood composite structural beams are replacing steel beams because of their performance, light weight, and ease to work with, and competitive price.

A thermoplastic material cannot replace the steel in automotive disc or drum brake housings because the product requires dimensional stability, low thermal expansion, and high strength and rigidity at elevated temperatures. Thermoplastic resins do not meet the requirements. However, brake pads made of thermoset polyimide have been successfully used in airplanes.

Metals cannot replace automotive rubber tires, bellows, diaphragms, or compression seals because metals do not have the elasticity, fatigue endurance, wear resistance, and toughness of rubber or thermoplastic elastomers (TPEs). Metals are not used for light-weight and compact cellular phone housings because metals are electrical conductors, heavier, corrodible, and expensive.

Automotive cast iron engines and aluminum intake manifolds are being replaced by fiberglass reinforced nylon to lower the weight and improve the engine efficiency. These substitutions require new manufacturing processes but present opportunities for cost reduction. Automotive bumpers, external side panels, doors, fenders, and hoods made from steel are being replaced by plastics such as thermoplastic elastomer olefins (IPOs), thermoset composites, and polycarbonate alloys. These tough plastic materials have reduced weight and lower manufacturing costs, while providing added freedom for design and styling.

Portable electric tools and small kitchen appliance housings are no longer made of die cast iron, steel, or aluminum, but have been replaced with nylon and acrylonitrile-butadiene-styrene (ABS). These plastics improve the toughness, electrical insulation, design flexibility, and styling; they also weigh less, and provide efficient molding at lower costs.

Water faucet valves made of die cast steel, brass, or copper are being replaced by new designs, updated styles, and colors, using acetal resins, which eliminates corrosion, reduces cost and presents new market opportunities.

Large irrigation valves for high performance applications (1.50–3.0 in. diameter) and small valves (0.75 and 1.00 in. diameter) used to be made of die cast steel and brass. The large valves have been successfully replaced with glass reinforced nylon 6/12 and the small valves with glass reinforced nylon 6/6 or acetal. This improved performance and reliability eliminates corrosion and allows cost reduction. Other low performance commercial valves made of rigid polyvinyl chloride (PVC) (lower cost) have also been produced for the irrigation market.

Toilet anti-siphon valves made of several brass and copper components have been replaced with a multifunctional design in acetal resin that improves performance, eliminates corrosion, and reduces cost. The valves made from acetal resin have shown excellent performance over a 30-year period.

The comparison of properties for material selection is an effective tool when applied to materials in the same family group. However, comparing properties between different material families is not recommended. The characteristics and process requirements for each material are developed for a particular need of the application, and the properties are obtained using test methods and equipment specific for each family of materials.

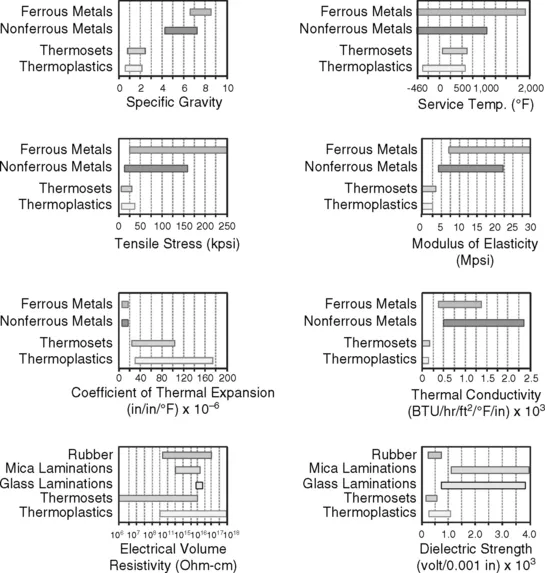

Figure 1.1 shows eight graphs using various generic property values to compare the strengths and weaknesses between families of materials.

The ferrous metal families include cast iron, cold rolled steel, structural steel, alloy steel, stainless steel, and tool steel.

The nonferrous metal families include magnesium, aluminum, copper, nickel, brass alloy, and titanium.

The thermoplastic families include ABS, acrylic, acetal, nylon, liquid crystal polymers (LCPs), polybutylene terephthalate (PBT), polyethylene terephthalate (PET), polystyrene (PS), polyethylene (PE), polypropylene (PP), polycarbonate (PC), polyphenylene oxide (PPO), polyetherimide (PEI), polyetherketone ketone (PEKK), polysulfone (PSU), polyphenylene sulfide (PPS), polytetrafluoroethylene (PTFE), polyvinyl chloride (PVC), and styrene-acrylonitrile (SAN).

The thermoset families include phenolics, silicones, alkyds, diallyl phthalate, polyimides, aminos, unsaturated polyesters, epoxies, and urethanes.

The rubber families include butadiene, butyl, chloroprene, nitrile, silicone, urethane, ethylene-propylene diene monomer (EPDM), ethylene-propylene monomer (EPM), fluorinated elastomer, and natural rubber.

The specific gravity graph shows the unit weight of a material compared to water and reveals that metals are two to eight times heavier than plastics. On a strength-to-weight basis, plastics have a more favorable position, as indicated by the specific gravity graph. The cost of metals is much higher than plastics.

The continuous exposure temperature graph shows that metals have a wider temperature range than plastics; metals can be used at colder and at elevated temperatures. The property and testing methods used for plastic materials are extremely important and critical for their classification and use temperature range.

The tensile strength graph shows that metals are much stronger than plastics; metals resist higher forces when they are pulled apart, before catastrophic failure. Time and temperature affect the tensile strength and cold flow (creep) properties of plastics; they decrease with increasing temperature over a much smaller temperature range, and exposure time.

The modulus of elasticity graph shows that metals have a higher resistance to deflection for short-term, intermittent, or continuous loading than plastics. Metals have better dimensional stability at elevated temperatures than plastics. Since plastics deflect more than metals under the same load, it is important that plastic products be loaded using different techniques. For plastics the load should be intermittent and well distributed in compression mode.

The coefficient of linear thermal expansion graph shows that increasing the temperature causes higher dimensional changes for plastics than for metals when plastics and metals are used together in the same application and exposed to the same temperatures. The plastic parts expand more than the metal parts, thus requiring design modifications to compensate for the dimensional change in plastics.

The thermal conductivity graph shows that metals are good conductors of heat, while plastics are excellent insulators. Despite their relatively low use temperature range, plastics may be superior to metals as high temperature heat shields for short exposures. A plastic part exposed to a radiant heat source may suffer surface degradation. However, this heat is not transmitted to the opposite surface as rapidly as in metals.

The electrical volume resistivity graph compares only the insulation materials used in electrical applications because metals are conductors.

The dielectric breakdown strength graph shows the voltage gradient at which electrical failure or breakdown occurs as a continuous arc; the higher the value, the better the material. Plastics have excellent electrical resistance properties, while metals are conductors.

1.1 Tensile Stress-Strain Comparison Graphs

The tensile strength, strain, and modulus of elasticity are among the most ...