- 568 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

The past decade has witnessed dramatic growth in the diversity and complexity of device applications where vacuum is required to support either high voltages or high electric fields. This is particularly true in thespace industry, specifically for the development of space-based pulse power systems.

This book presents an overview of the technological advances that have occurred since the publication of the Editors earlier book High Voltage Vacuum Insulation: The Physical Basis. In this latest book, contributions from internationally recognized professionals and researchers in the field provide expanded treatment of the practical aspects of the subject. High Voltage Vacuum Insulation: Basic Concepts and Technological Practice provides a modern working manual for this specialized technology that is generic to a wide range of applications. The format makes the text suitable for use as a basis for special topic lecture courses at either the undergraduate or graduate level.

- Provides the fundamental physical concepts of the subject

- Focuses on practical applications

- Gives a historical survey of the field

- Includes a detailed account of system design criteria

- Reviews theoretical models developed to explain the pinhole phenomena

- Presents results of a series of experimental investigations on the subject

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

RV Latham

1.1 The Breakdown Phenomenon

1.2 Historical Background

1.3 Practical Considerations

1.4 Technological Applications

1.5 Reviews and Bibliographies

1.6 References

1.1 The Breakdown Phenomenon

Although vacuum is used extensively for the insulation of high voltages in such devices as X-ray tubes, electron microscopes, power vacuum switches, particle accelerators and separators etc., the reliability of its performance is limited by the operational risk of an unpredictable “sparking” or “arcing” between the high voltage electrodes, when the insulating capability of the vacuum gap is suddenly lost and “electrical breakdown” is said to have occurred. For some devices, such as sealed-off high voltage vacuum diodes with oxide cathodes, a breakdown event is likely to be an irreversible process and catastrophic from both the operational and financial points of view since, not only will the cathode probably be damaged, but the high voltage gap is subsequently likely to break down at a very much lower voltage: at all events, the future performance of the device will almost certainly be permanently impaired.

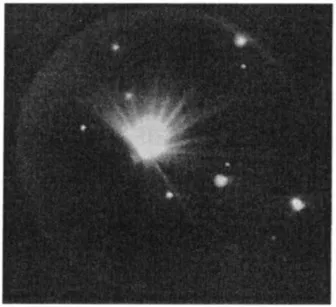

In other applications however, such as vacuum switches and particle separators, occasional breakdown events, although undesirable, can generally be tolerated without disastrous consequences: that is, provided special precautions are taken to control the energy that is available in the external circuitry for dissipation in a gap during a breakdown event. To illustrate the dramatic nature of such breakdown events, Fig 1.1 is a highspeed photograph, recorded in the author’s laboratory, of a discharge event between two plane-parallel electrodes. It shows the “explosion” of an isolated prebreakdown electron emission site, or “pin-hole”, captured with the aid of the Transparent Anode technique to be described in Chapter 3.

Fig 1.1 A high speed video image illustrating the “explosive” nature of a vacuum breakdown event.

Not surprisingly, this practical limitation of the insulating capability of vacuum has had a profound influence on the design of high voltage vacuum equipment: in the short term, the problem is conventionally tackled by such empirical and often expensive procedures as maximising the dimensions of vacuum gaps, using special electrode materials and surface preparation techniques, or incorporating sophisticated electronic protection circuitry. For the long term, there has been a considerable research investment directed towards obtaining an understanding of the fundamental physical processes that give rise to breakdown, so that by taking informed precautions the insulating capability of high voltage vacuum gaps can be improved. It is with the details of this research programme and the technological implications of its findings that this book is principally concerned.

The most serious hazard in the early applications of vacuum insulation was the presence of excessive residual gas, which manifested itself either directly as a relatively high ambient pressure in the gap, probably little better than ∼ 10−6−10−5 mbar, or indirectly as transient pressure bursts caused by the thermal desorption of gas from the electrodes and vacuum chamber walls by localised electron or ion bombardment processes. Thus, if the local pressure p in the gap approaches a value where the mean free path of electrons becomes less than the dimension of the electrode gap d, the necessary conditions will be created for avalanche ionisation and the spontaneous establishment of an arc between the electrodes. This situation has been quantified as the well known Paschen Law [1], which defines the sparking or breakdown potential Vb in terms of a function of the product pd whose detailed form can be found, for example, in the writings of Von Engel [2], Morgan [3] and Llewellyn-Jones [4] on the electrical properties of low pressure ionised gases. However, as a result of the many advances that have taken place in high vacuum technology, where it is now standard practice to use baked-out vacuum systems in which ambient pressures of <10−7 mbar can be guaranteed, this mechanism of electrical breakdown is no longer regarded as a threat and, accordingly, will receive no further treatment in this text.

Thus, whilst the use of relatively gas-free ultra high vacuum (UHV) conditions greatly improves the high-voltage insulating capability of a vacuum gap, its electrical breakdown is still ultimately initiated by some form of discharge process arising from the creation of an ionisable medium in the gap. Since this can now only be derived from an increase in the local metal vapour pressure, it follows that any physical explanation of this form of breakdown must be based upon electrode surface processes that lead to the vaporisation of electrode material.

1.2 Historical Background

The breakdown phenomenon was first investigated scientifically by Wood [5] in 1897 and somewhat later by Earhart [6], Hobbs [7] and Millikan and Sawyer [8]. From these early studies it was established that, even prior to breakdown, a vacuum gap has a small but finite conductivity as evidenced by the flow of “prebreakdown” currents whose magnitude increased rapidly with increasing gap voltage until breakdown occurred. For mm gap separations, it was found that the corresponding breakdown field was typically ∼ 108 Vm−1, although it depended somewhat on the electrode material. A further observation of considerable practical significance was that the breakdown voltage was independent of pressure in the range 10−8−10−5 mbar. Millikan and Sawyer [8] also discovered that the voltage hold-off capability of a given gap can be significantly improved if it is subjected to an initial “conditioning” procedure (see Section 2.3) whereby the voltage is increased in small steps such that all major prebreakdown current instabilities are allowed to decay before the next voltage increment is applied. In 1920, Millikan and his subsequent co-workers [9–11] embarked on a decade of study into the source of the noisy but reversible component of the prebreakdown currents that flow between a pair of broad-area high voltage electrodes. They established that they were electronic and originated from a cold emission process (now known as field electron emission − FEE) at isolated points on the surface of the cathode which gave rise to complementary fluorescent spots on the anode.

At this time, these emission sites were assumed to be localised regions of the electrode surfaces where there was either an “effective” reduction in the work function through the Schottky effect [12] at field-enhancing microfeatures associated with the intrinsic microscopic roughness of electrode surfaces, or with a “real” reduction in the work function due to the presence of isolated chemical impurities. The noisy nature of the currents was attributed to the back-sputtering of ions produced by electron collision processes in the gap. Millikan and Lauritsen [11] also established that this prebreakdown current I had a well-defined empirical dependence on the gap field E such that a graph of log I versus 1/E gave a reversible straight line, i.e. I = A exp (−B/A) where A and B are constants. It was found however that the slope B and intercept A of such plots were very sensitive to the electrode surface conditions. Other early workers of note whose principal concern was with the origin and role of these highly localised cold emission processes included Hull and Burger [13], Snoddy [14], Beams [15] and Ahearn [16]. The initial conclusion to emerge from their studies was that breakdown was due to the intense localised heating and consequent vaporisation of the anode by the bombardment of electrons emitted from these point sources. However, Ahearn [16] extended the understanding of the phenomenon by considering the possibility of breakdown being cathode initiated following the field-induced rupture of current emitting projections.

One of the first really comprehensive investigations into how the operational breakdown voltage of a gap depends on such practical parameters as the electrode material, surface preparation and gap spacing etc. was undertaken by Anderson [17] in 1935. Although the general practical conclusions to emerge from this and many subsequent studies of its kind will be reviewed in Chapter 2, special mention should be made in this historical context of Anderson’s identification of the “total voltage effect”. This is associated with large cm-gap regimes supporting hundreds as opposed to tens of kilovolts, where it is found that breakdown tends to be voltage rather than field-dependent, and not apparently related to the prebreakdown electron emission currents which are frequently absent or negligible in such regimes, i.e. where the macroscopic gap fields are significantly lower than those existing in the earlier mm-gap studies of cold emission processes. To illustrate this distinction, it can be pointed out that, whereas it is possible for a 0.5 mm vacuum gap to support ∼ 20 kV without breaking down, a 10 cm gap will support less than 1 MV.

Another important observation associated with this type of large-gap br...

Table of contents

- Cover image

- Title page

- Table of Contents

- Dedication

- Copyright

- Author Profiles

- Preface

- Acknowledgements

- Editor’s Notes

- Symbols and Abbreviations

- Chapter 1: Introduction

- Part I: Basic Concepts

- Part II: Technological Practice

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access High Voltage Vacuum Insulation by Rod V. Latham in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Condensed Matter. We have over one million books available in our catalogue for you to explore.