Surface Production Operations: Volume III: Facility Piping and Pipeline Systems

- 1,090 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Surface Production Operations: Volume III: Facility Piping and Pipeline Systems

About this book

Surface Production Operations: Facility Piping and Pipeline Systems, Volume III is a hands-on manual for applying mechanical and physical principles to all phases of facility piping and pipeline system design, construction, and operation. For over twenty years this now classic series has taken the guesswork out of the design, selection, specification, installation, operation, testing, and trouble-shooting of surface production equipment.The third volume presents readers with a "hands-on" manual for applying mechanical and physical principles to all phases of facility piping and pipeline system design, construction, and operation. Packed with charts, tables, and diagrams, this authoritative book provides practicing engineer and senior field personnel with a quick but rigorous exposition of piping and pipeline theory, fundamentals, and application.Included is expert advice for determining phase states and their impact on the operating conditions of facility piping and pipeline systems; determining pressure drop and wall thickness; and optimizing line size for gas, liquid, and two-phase lines. Also included are a guide to applying international design codes and standards, and guidance on how to select the appropriate ANSI/API pressure-temperature ratings for pipe flanges, valves, and fittings.- Covers new and existing piping systems including concepts for expansion, supports, manifolds, pigging, and insulation requirements- Presents design principles for a pipeline pigging system- Teaches how to detect, monitor, and control pipeline corrosion- Reviews onshore and offshore safety and environmental practices- Discusses how to evaluate mechanical integrity

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

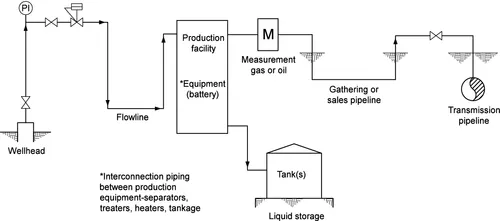

Overview of facility piping and pipeline systems

Abstract

1.1 Overview

1.2 Introduction to piping design and projects

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface

- Acknowledgments

- 1: Overview of facility piping and pipeline systems

- 2: Piping standards, codes, and recommended practices

- 3: Material requirements: Piping materials

- 4: Piping system components

- 5: Engineering drawings: data sheets and symbols

- 6: Fluid flow and pressure drop

- 7: Choosing a line size and wall thickness

- 8: Relief, vent and flare disposal systems

- 9: Piping system design: Layout, supports, and piping vessels and equipment

- 10: Pipe expansion and flexibility

- 11: Pipeline systems

- 12: Pressure testing and nondestructive examination

- 13: Pipeline pigging

- 14: Pipeline operations

- Appendix 1

- Appendix 2

- Appendices 3A–3G

- Appendix 4

- Appendix 5

- Appendix 6

- Appendix 7

- Appendix 8

- Appendix 9

- Appendix 10

- Appendix 11

- Appendix 12

- Appendix 13

- Appendix 14

- Index