- 608 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Sputtering Materials for VLSI and Thin Film Devices

About this book

An important resource for students, engineers and researchers working in the area of thin film deposition using physical vapor deposition (e.g. sputtering) for semiconductor, liquid crystal displays, high density recording media and photovoltaic device (e.g. thin film solar cell) manufacturing. This book also reviews microelectronics industry topics such as history of inventions and technology trends, recent developments in sputtering technologies, manufacturing steps that require sputtering of thin films, the properties of thin films and the role of sputtering target performance on overall productivity of various processes. Two unique chapters of this book deal with productivity and troubleshooting issues.

The content of the book has been divided into two sections: (a) the first section (Chapter 1 to Chapter 3) has been prepared for the readers from a range of disciplines (e.g. electrical, chemical, chemistry, physics) trying to get an insight into use of sputtered films in various devices (e.g. semiconductor, display, photovoltaic, data storage), basic of sputtering and performance of sputtering target in relation to productivity, and (b) the second section (Chapter 4 to Chapter 8) has been prepared for readers who already have background knowledge of sputter deposition of thin films, materials science principles and interested in the details of sputtering target manufacturing methods, sputtering behavior and thin film properties specific to semiconductor, liquid crystal display, photovoltaic and magnetic data storage applications.

In Chapters 5 to 8, a general structure has been used, i.e. a description of the applications of sputtered thin films, sputtering target manufacturing methods (including flow charts), sputtering behavior of targets (e.g. current - voltage relationship, deposition rate) and thin film properties (e.g. microstructure, stresses, electrical properties, in-film particles). While discussing these topics, attempts have been made to include examples from the actual commercial processes to highlight the increased complexity of the commercial processes with the growth of advanced technologies. In addition to personnel working in industry setting, university researchers with advanced knowledge of sputtering would also find discussion of such topics (e.g. attributes of target design, chamber design, target microstructure, sputter surface characteristics, various troubleshooting issues) useful.

.

- Unique coverage of sputtering target manufacturing methods in the light of semiconductor, displays, data storage and photovoltaic industry requirements

- Practical information on technology trends, role of sputtering and major OEMs

- Discussion on properties of a wide variety of thin films which include silicides, conductors, diffusion barriers, transparent conducting oxides, magnetic films etc.

- Practical case-studies on target performance and troubleshooting

- Essential technological information for students, engineers and scientists working in the semiconductor, display, data storage and photovoltaic industry

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Sputtering Materials for VLSI and Thin Film Devices by Jaydeep Sarkar in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Sputtering Targets and Sputtered Films for the Microelectronic Industry

A wide variety of materials are sputtered either in pure or in reactive mode to form thin films on chosen substrates for microelectronic applications. Such sputtered thin films are used as silicide contacts, conductors, diffusion barriers, anti-reflection coatings, transparent conducting oxides, reflective layer, semi-reflective layer, dielectric layer, recording media, absorber layer and so forth. In this chapter, commercially important sputtering targets and sputtering chambers (tools) for semiconductor, display, data storage and photovoltaic industries have been identified. This chapter also reviews essential semiconductor, active matrix liquid crystal display (AMLCD), data storage (e.g. magnetic, optical, phase change) and photovoltaic industry topics which include (a) major inventions, (b) technology trends, (c) process flows for device manufacturing, (d) original equipment manufacturers (OEMs) and (e) sputtering target suppliers.

Keywords

Metallization; Interconnect; Thin films; Physical vapor deposition (PVD); PVD tools; Sputtering targets; Semiconductor; Integrated circuits (ICs); Silicide; Salicide; Conductors; Diffusion barriers; Liquid crystal displays; Thin film transistor (TFT); Transparent conducting oxides (TCOs); Indium tin oxide (ITO); Magnetic recording; Inductive head; MR head; GMR head; Longitudinal media; Perpendicular media; Optical storage media; Phase change materials; Photovoltaic devices

1.1 Materials for microelectronics

1.1.1 Introduction

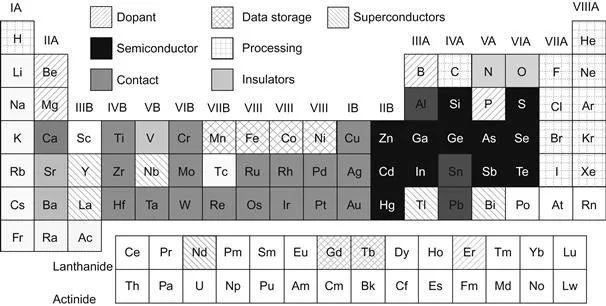

The microelectronic industry arguably uses a wide variety of materials in the form of solid, liquid, gas and gas plasma in microelectronic device components and for the processing of devices. Figure 1.1 shows these elements in the periodic table. Choices for material selection are made based on the applications [1]. With the exception of actinides (the bottom-most row) and a few other unstable and less common elements, most of the elements are used in microelectronics industry. A large number of such elements and their alloys are used in microelectronics devices in the form of thin films [2–20]. Sputtering is one of the techniques for depositing such thin films in which atoms are ejected from a source material by using energetic particles inside a chamber [4,6,14]. In principle, the majority of solid materials can be sputtered under suitable conditions to form thin films. Chapter 2 reviews various sputtering methods for depositing thin films and device technology driven evolution of sputtering equipment (also known as sputtering tools). Sputtering can also be used to remove a thin layer of material from a substrate and this application of sputtering is out of the scope of this book.

Figure 1.1 Periodic table showing elements and their applications in microelectronic industry [1].

The primary focus of this book is to discuss metallurgy and material science of sputtering materials that are technologically important. These include both: (a) bulk source materials, known as sputtering targets, and (b) deposited thin films for microelectronic applications. Sputtering target can be a conductor, semiconductor or an insulator. Conductivity is one of the key parameters that contrast these three types of solids. As one would expect, a small section of a chapter of this nature has limited scope to cover this subject. Hence, the following sections will only summarize the general characteristics of conduction in conductors, semiconductors and insulators. Afterwards, discussion has been shaped in such a way that readers eventually arrive at those technologically important materials that are sputtered to form thin films for making commercial device such as integrated circuits (ICs), displays, magnetic and optical data storage systems, photovoltaic solar cell and so forth [2–20]. As discussion progresses, readers will note that sputtering is primarily used to deposit metal-based conductors and not so much for semiconductor and insulators (with some exceptions). It is important for readers to note that, in many cases, by the time thin films are sputter deposited on a substrate, a significant amount of investment has already been done for substrate preparation. As a result, any failure at the sputter deposition stage will reduce the overall yield and productivity of the process. For example, in a complementary metal oxide semiconductor (CMOS) chip manufacturing process, by the time a cobalt or nickel film is sputter deposited prior to the silicide formation, active regions have already been formed on the silicon wafer with significant investment.

1.1.1.1 Electrical conductivity

The most common approach to distinguishing conductors, semiconductors and insulators for microelectronic applications is based on their electrical conductivity (reciprocal of resistivity) values. Electrical conductivity (σ) of a material is given by the equation

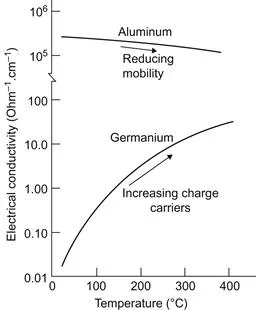

where n is the number of carriers, q is the charge and μ is the mobility of the carriers. While conductors have high electrical conductivity (104–106 ohm−1 cm−1) insulators have low electrical conductivity (≤10−15 ohm−1 cm−1) and semiconductors have intermediate electrical conductivity (10−6–103 ohm−1 cm−1). These boundaries are not rigid and a certain degree of overlap is possible between these sets of values. In general, the electrical conductivity of the conductors shows a slight but gradual drop with increasing temperature. This is because n is large for conductors and essentially remains unchanged with temperature. Similarly, q remains constant but the mobility term μ decreases slightly with increasing temperature. The mobility of the carriers decreases because of the collision between moving electrons and the phonons (lattice vibrations). Silver, copper and gold are among the best electrical conductors. Transition metals such as iron and nickel are not as good conductors as above metals. However, for semiconductors and the insulators, n increases dramatically with temperature unlike conductors which outweighs the slight decrease in the mobility term. As a result, electrical conductivity of semiconductors increases rapidly with temperature.

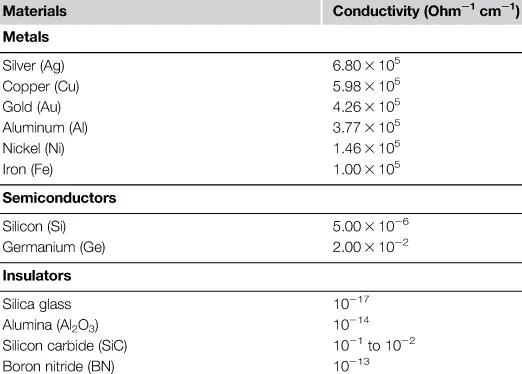

Table 1.1 lists the electrical conductivity of some of the common materials at room temperature. Figure 1.2 shows the variation of electrical conductivity in aluminum and germanium with temperature. In fact, insulators are extreme state semiconductors when n is small at normal temperature. In the following sections, a cursory review of the principles of conduction in solids (conductors, semiconductors and insulators) has been presented prior to the discussion of various devices that integrate such materials. Finally, the discussion leads to those conductors, semiconductors and insulators that are sputtered to form films for device fabrication.

Table 1.1

Electrical Conductivity of Selected Bulk Materials

Figure 1.2 Variation of electrical conductivity in aluminum (Al) and germanium (Ge) with temperature.

The electronic behavior of s...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- Chapter 1. Sputtering Targets and Sputtered Films for the Microelectronic Industry

- Chapter 2. Sputtering and Thin Film Deposition

- Chapter 3. Performance of Sputtering Targets and Productivity

- Chapter 4. Sputtering Target Manufacturing

- Chapter 5. Sputtering Targets and Thin Films for Integrated Circuits

- Chapter 6. Sputtering Targets and Thin Films for Flat Panel Displays and Photovoltaics

- Chapter 7. Ferromagnetic Sputtering Targets and Thin Films for Silicides and Data Storage

- Chapter 8. Troubleshooting in Sputter Deposition

- Index