Automotive Buzz, Squeak and Rattle

Mechanisms, Analysis, Evaluation and Prevention

- 296 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Automotive Buzz, Squeak and Rattle

Mechanisms, Analysis, Evaluation and Prevention

About this book

Buzz, squeak, and rattle (BSR) is the automotive industry term for the audible engineering challenges faced by all vehicle and component engineers. Minimizing BSR is of paramount importance when designing vehicle components and whole vehicle assemblies. This is the only book dedicated to the subject. It provides a self-contained reference to the background theory, testing, analysis, and elimination of BSR. Written for practicing engineers and industry researchers, the book has a strong focus on real-world applications making it an ideal handbook for those working in this important area. Chapters from leading experts from across the motor industry—with input from the design and research labs of Ford, Toyota, Daimler-Chrysler and GM—review the techniques available and provide readers with the appropriate physics, structural dynamics and materials science to address their own BSR issues.- The only book available on automotive BSR (buzz, squeak and rattle)—the number one cause of complaint on new cars- Comprehensive and authoritative, with contributions from leading figures in the field and companies such as Ford, Toyota and Daimler-Chrysler- Enables readers to understand and utilize the complex tools used to assess, identify and rectify BSR in vehicle design and testing

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Frank Chen and Martin Trapp

Chapter Outline

1.1. Customer Expectation and Vehicle Quality

|

|

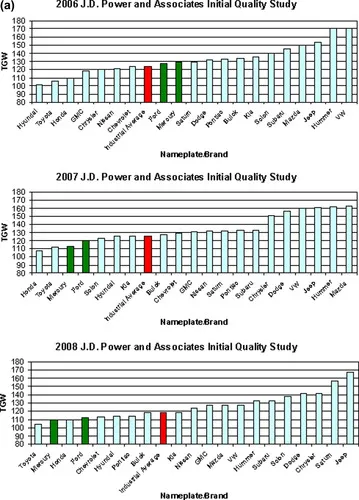

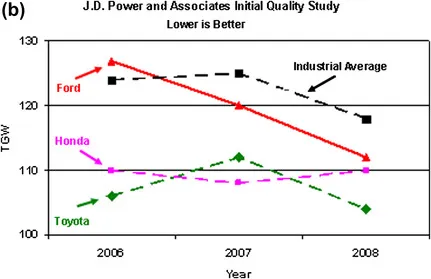

| Figure 1.1 (a) Three years (2006/2007/2008) of JD Power and Associates Initial Quality Study on TGW. (b) Trend of JD Power and Associates IQS in the past three years for Ford, Toyota, Honda and Industrial Average. |

Table of contents

- Cover image

- Table of Contents

- Front Matter

- Copyright

- Chapter 1. Overview on Vehicle Buzz, Squeak and Rattle

- Chapter 2. Friction Sliding and Rattle Impact Analysis

- Chapter 3. Stick-Slip Characteristics of Leather/Artificial Leather

- Chapter 4. Material Pair Testing and Instrumentation

- Chapter 5. Full Vehicle Testing

- Chapter 6. Buzz, Squeak and Rattle Detection for Modules, Subsystems and Components

- Chapter 7. Universal Graining to Prevent Creaking Noises with Plastic and Elastic Contact Partners

- Chapter 8. Squeak and Rattle CAE Simulation Using FEA

- Chapter 9. Squeak and Rattle Prevention in the Design Phase Using a Pragmatic Approach

- Chapter 10. Experimental Friction Behavior of Elastomers on Glass

- Chapter 11. Development of Squeak and Rattle Countermeasures Through Up-Front Designs

- Chapter 12. Coatings for Low-Noise Body Seals

- Index