UHMWPE Biomaterials Handbook

Ultra High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices

- 568 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

UHMWPE Biomaterials Handbook

Ultra High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices

About this book

UHMWPE Biomaterials Handbook describes the science, development, properties and application of of ultra-high molecular weight polyethylene (UHMWPE) used in artificial joints. This material is currently used in 1.4 million patients around the world every year for use in the hip, knee, upper extremities, and spine.Since the publication of the 1st edition there have been major advances in the development and clinical adoption of highly crosslinked UHMWPE for hip and knee replacement. There has also been a major international effort to introduce Vitamin E stabilized UHMWPE for patients. The accumulated knowledge on these two classes of materials are a key feature of the 2nd edition, along with an additional 19 additional chapters providing coverage of the key engineering aspects (biomechanical and materials science) and clinical/biological performance of UHMWPE, providing a more complete reference for industrial and academic materials specialists, and for surgeons and clinicians who require an understanding of the biomaterials properties of UHMWPE to work successfully on patient applications.- The UHMWPE Handbook is the comprehensive reference for professionals, researchers, and clinicians working with biomaterials technologies for joint replacement- New to this edition: 19 new chapters keep readers up to date with this fast moving topic, including a new section on UHMWPE biomaterials; highly crosslinked UHMWPE for hip and knee replacement; Vitamin E stabilized UHMWPE for patients; clinical performance, tribology an biologic interaction of UHMWPE- State-of-the-art coverage of UHMWPE technology, orthopedic applications, biomaterial characterisation and engineering aspects from recognised leaders in the field

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Chapter 1. A Primer on UHMWPE

1.1. Introduction

Figure 1.1. Dump truck liner of UHMWPE, an example of an industrial application for the polymer.

1.2. What is a Polymer?

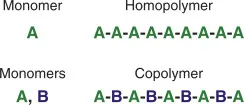

Figure 1.2. Schematics of homopolymer and copolymer structure.

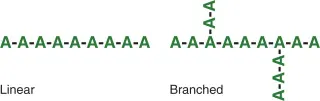

Figure 1.3. Schematics of linear and branched polymer structures.

Table of contents

- Brief Table of Contents

- Table of Contents

- Copyright Page

- Dedication

- Foreword

- Contributors

- Chapter 1. A Primer on UHMWPE

- BibliographyReferences

- Chapter 2. From Ethylene Gas to UHMWPE Component

- BibliographyReferences

- Chapter 3. Packaging and Sterilization of UHMWPE

- BibliographyReferences

- Chapter 4. The Origins of UHMWPE in Total Hip Arthroplasty

- BibliographyReferences

- Chapter 5. The Clinical Performance of UHMWPE in Hip Replacements

- BibliographyReferences

- Chapter 6. Contemporary Total Hip Arthroplasty

- BibliographyReferences

- Chapter 7. The Origins and Adaptations of UHMWPE for Knee Replacements

- BibliographyReferences

- Chapter 8. The Clinical Performance of UHMWPE in Knee Replacements

- BibliographyReferences

- Chapter 9. The Clinical Performance of UHMWPE in Shoulder Replacements

- BibliographyReferences

- Chapter 10. The Clinical Performance of UHMWPE in Elbow Replacements

- BibliographyReferences

- Chapter 11. Applications of UHMWPE in Total Ankle Replacements

- BibliographyReferences

- Chapter 12. The Clinical Performance of UHMWPE in the Spine

- BibliographyReferences

- Chapter 13. Highly Crosslinked and Melted UHMWPE

- BibliographyReferences

- Chapter 14. Highly Crosslinked and Annealed UHMWPE

- BibliographyReferences

- Chapter 15. Highly Crosslinked UHMWPE Doped with Vitamin E

- BibliographyReferences

- Chapter 16. Vitamin-E-Blended UHMWPE Biomaterials

- BibliographyReferences

- Chapter 17. Composite UHMWPE Biomaterials and Fibers

- BibliographyReferences

- Chapter 18. UHMWPE/Hyaluronan Microcomposite Biomaterials

- BibliographyReferences

- Chapter 19. High Pressure Crystallized UHMWPEs

- BibliographyReferences

- Chapter 20. Compendium of Highly Crosslinked UHMWPEs

- BibliographyReferences

- Chapter 21. Mechanisms of Crosslinking, Oxidative Degradation and Stabilization of UHMWPE

- BibliographyReferences

- Chapter 22. In Vivo Oxidation of UHMWPE

- BibliographyReferences

- Chapter 23. Pathophysiologic Reactions to UHMWPE Wear Particles

- BibliographyRefereneces

- Chapter 24. Characterization of Physical, Chemical, and Mechanical Properties of UHMWPE

- BibliographyReferences

- Chapter 25. Tribological Assessment of UHMWPE in the Hip

- BibliographyReferences

- Chapter 26. Tribological Assessment of UHMWPE in the Knee

- BibliographyReferences

- Chapter 27. Characterization of UHMWPE Wear Particles

- BibliographyReferences

- Chapter 28. Clinical Surveillance of UHMWPE Using Radiographic Methods

- BibliographyReferences

- Chapter 29. ESR Insights into Macroradicals in UHMWPE

- BibliographyReferences

- Chapter 30. Fatigue and Fracture of UHMWPE

- BibliographyReferences

- Chapter 31. Development and Application of the Notched Tensile Test to UHMWPE

- BibliographyReferences

- Chapter 32. Development and Application of the Small Punch Test to UHMWPE

- BibliographyReferences

- Chapter 33. Nano- and Microindentation Testing of UHMWPE

- BibliographyReferences

- Chapter 34. MicroCT Analysis of Wear and Damage in UHMWPE

- BibliographyReferences

- Chapter 35. Computer Modeling and Simulation of UHMWPE

- BibliographyReferences

- Index