Tribology of Abrasive Machining Processes

- 751 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Tribology of Abrasive Machining Processes

About this book

Recent and radically improved machining processes, from high wheel speeds to nanotechnology, have turned a spotlight on abrasive machining processes as a fertile area for further advancements. Written for researchers, students, engineers and technicians in manufacturing, this book presents a fundamental rethinking of important tribological elements of abrasive machining processes and their effects on process efficiency and product quality. Newer processes such as chemical mechanical polishing (CMP) and silicon wafer dicing can be better understood as tribological processes. Understanding the tribological principles of abrasive processes is crucial to discovering improvements in accuracy, production rate, and surface quality of products spanning all industries, from machine parts to ball bearings to contact lens to semiconductors.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1.1 ABRASIVE PROCESSES

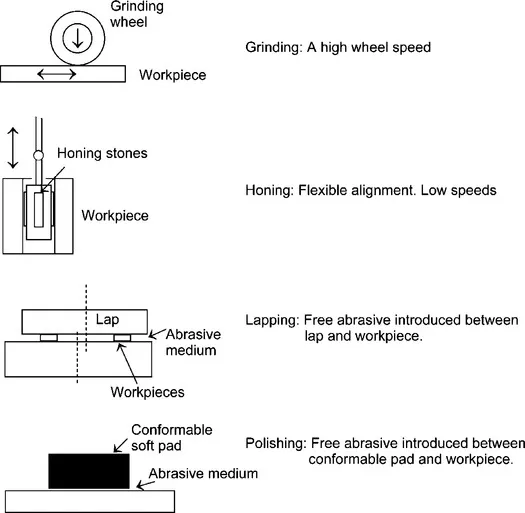

1.1.1 Grinding

1.1.2 Honing

1.1.3 Lapping

1.1.4 Polishing

1.2 ABRASIVES

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Related Titles

- Preface

- Chapter 1: Introduction

- Chapter 2: Tribosystems of Abrasive Machining Processes

- Chapter 3: Kinematic Models of Abrasive Contacts

- Chapter 4: Contact Mechanics

- Chapter 5: Forces, Friction, and Energy

- Chapter 6: Thermal Design of Processes

- Chapter 7: Molecular Dynamics for Abrasive Process Simulation

- Chapter 8: Fluid Delivery

- Chapter 9: Electrolytic In-process Dressing (ELID) Grinding and Polishing

- Chapter 10: Grinding Wheel and Abrasive Topography

- Chapter 11: Abrasives and Abrasive Tools

- Chapter 12: Conditioning of Abrasive Wheels

- Chapter 13: Loose Abrasive Processes

- Chapter 14: Process Fluids for Abrasive Machining

- Chapter 15: Tribochemistry of Abrasive Machining

- Chapter 16: Processed Materials

- Symbols and Units

- Glossary

- Index