eBook - ePub

Extrusion

The Definitive Processing Guide and Handbook

- 560 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Extrusion

The Definitive Processing Guide and Handbook

About this book

Why is it important to get to equilibrium and how long does it take? Are there problems running polypropylene profiles on a single screw extruder? Does the job involve compounding color concentrates on a corotating twin screw extruder? This unique reference work is designed to aid operators, engineers, and managers in quickly answering such practical day-to-day questions in extrusion processing. This comprehensive volume is divided into 7 Parts. It contains detailed reference data on such important operating conditions as temperatures, start-up procedures, shear rates, pressure drops, and safety. This reference is a practical guide to extrusion bringing together both the equipment and materials processing aspects. It provides basic and advanced topics about the thermoplastics processing in the extruder, for reference and training. Parts 1 û 3, emphasize the fundamentals, for operators and engineers, of polymeric materials extrusion processing in single and twin screw extruders. Parts 4 û 7 treat advanced topics including troubleshooting, auxiliary equipment, and coextrusion for operators, engineers, and managers. Extensive applications in Part 7 cover such contemporary areas as compounding, blown film, extrusion blow molding, coating, foam, and reprocessing. Each chapter includes review topics.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Extrusion Process

The extrusion of polymeric materials to produce finished products for industrial or consumer applications is an integrated process, with the extruder comprising one component of the entire line. In some applications the production lines are very long with numerous operations, requiring operators to communicate and work together to produce an acceptable finished product. If the extruder temperature profile is set incorrectly, the product ingredients are not properly formulated, the cooling on the extruder feed throat is not running properly, the melt temperature at the end of the extruder is incorrect, the cooling bath temperature is not set correctly, the puller at the end of the line is running at the wrong speed, or any other incorrect operating condition or combinations of conditions, the product may not meet customer specifications. Each step in the process adds value; consequently, theproduct reaches its maximum value at the end of the line. An improper setting at the beginning of the process may cause the product to be unacceptable at the end of the line after significantly more value has been added. Speeds of the different process steps must be matched to ensure product compliance.

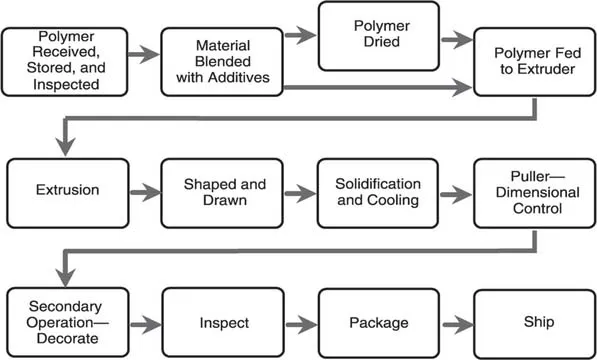

The extrusion process is shown in Figure 1.1. Polymeric material is received, inspected, and stored. Prior to extrusion, the polymer may be blended with additives (stabilizers for heat, oxidative stability, UV stability, etc.), color pigments or concentrates, flame retardants, fillers, lubricants, reinforcements, etc., to produce the desired product property profile. Some resin systems must be dried prior to extrusion to eliminate polymer degradation due to moisture. Other resins, which do not normally require drying, may have to be dried if they are stored in a cold warehouse and brought into a warm environment, causing moisture to condense on the surface of the pellets, flake, or powder. Once the polymer or blend is properly dried and ingredients mixed, the formulation is fed to the extruder, where it is melted, mixed, and delivered to the die to shape the extrudate. After exiting the die, the product is cooled and solidified in the desired shape and pulled away from the extruder at constant velocity to attain the appropriate cross section. Secondary operations, i.e., flame treatment, printing, cutting, annealing, etc., can be done in line after the puller. Finally, the product is inspected, packaged, and shipped.

Figure 1.1. Basic extrusion process schematic.

The different parts of the process are discussed in more detail in this chapter.

1.1 Raw Material Supply

Polymer resin is shipped in different size containers depending on the quantity ordered, the processors’ handling and storage capability, and the way the extruder is fed. Small lots are shipped in 50- or 55-pound bags, and large lots are shipped by tanker truck or rail. Table 1.1 shows different shipping methods. Plastic pellets can be air- or vacuum-conveyed around the plant to storage containers or the extruder hopper.

Table 1.1. Plastic Packaging

| Package Size, Pounds | Type Package |

|---|---|

| 50–55 | Bags |

| 300 | Fiber Pack |

| 1,000 | Gaylord |

| 4,000 | Bulk Pack |

| 40,000 | Hopper Truck |

| 150,000–220,000 | Rail Car |

Pellets conveyed between storage silos, dryers, surge hoppers, and extruder hoppers must be in dedicated or properly cleaned lines to prevent product cross-contamination. All lines must be properly grounded to eliminate static electricity build-up during the resin transfer process.

Raw materials stored in warehouses without environmental controls (lack of heat or cooling) need to be brought to room temperature prior to extrusion. If the raw material temperatures vary between summer and winter, the polymer melting or softening point in the extruder will occur at a different location, leading to different melt viscosities, extrudate flow, and possible product inconsistency from season to season. Assume the raw material temperature is 50°F (10°C) in the winter and 80°F (26°C) in the summer. Additional heat must be added to the raw material during the winter months, either by a hopper dryer, allowing the polymer to come to equilibrium at room temperature, or by adding additional heat in the first zones to ensure the polymer is melting or being plasticated in the transition zone. Due to the insulative nature of polymers, a significant time period is required to heat cold pellets that sat in a cold warehouse or in a cold truck to room temperature.

Storing raw materials in a hot environment over an extended time can lead to consuming the polymer stabilization package. Most thermal stabilization packages are consumed over time as the polymer is heated. While thermal degradation happens fairly rapidly at elevated temperatures in the presence of oxygen, degradation continues at a slower rate at elevated temperatures (above room temperature but below the melting or softening temperature). Stock should be rotated to minimize long-term thermal degradation.

Many raw materials are accepted from vendors based on a “certificate of compliance.” Good procedures dictate that incoming raw materials be periodically tested and a database of critical polymer properties be established. Most internal extrusion problems are not the result of raw material variations; however, in the event the wrong raw material is used, the processor should be able to identify any raw material inconsistencies immediately to minimize operating losses. Critical raw material properties for a particular application need to be identified and characterized so incoming materials are tested only for the properties that affect the final part performance. Critical properties may be viscosity, long-term heat aging, color, tensile properties, or other parameters, depending on particular end-use application.

1.2 Raw Material Blending and Mixing

Depending on the product requirements, some preblending or ingredient mixing may be required prior to extrusion. (Blending and mixing are covered in more detail in Part 5, “Auxiliary Equipment.”) Unless a single polymeric material is being added to an extruder, the best way to combine different raw materials and keep them uniformly distributed prior to entering the extruder feed throat depends on different factors. Some factors to consider are

• Separation of powder and pellets

• Uniform distribution of additives introduced at low concentrations

• Separation of ingredients in flood fed hoppers

• Proper mixing

• Introduction of different levels of regrind and/or the effect of regrind particle size

• Addition of liquid additives to a single screw extruder

• Uniform distribution of powder/powder blends

The best way to meter materials and guarantee uniform component distribution is to gravimetrically feed each component with different feeders directly above the extruder feed throat. Assuming there are enough space and feeders to accommodate the various components in the formulation, gravimetric or loss-in-weight feeding ensures each component is added in the correct proportion, while addition directly above the feed throat minimizes any ingredient segregation. The downside of this approach is the cost of gravimetric feeders, the space required if there are more than four or five components, and if different size feeders are required. Assuming some components are added in very low concentrations (<1%) while other components are added in high concentration (>15%), the feeder size, feeder accuracy, and material (powder, pellets, flake, free-flowing versus compressive powder, fiber, etc.) being fed are critical to the feeder performance. If all feeders are properly sized, designed for the materials being fed (single screw feeder, twin screw feeder, vibratory, weigh belt, etc.), and there is enough room to use a gravimetric feeder for each component, multiple feeders is the best method to ensure a repeatable, uniform formulation is being introduced to the extruder.

In many applications, a feeder is not available for each ingredient, requiring preblending. Blending depends on the ingredients being mixed and the way material is handled after blending and prior to extrusion. Assume pellets A and B are approximately the same size and are required to be premixed; proper concentrations of A and B are individually weighed and added to low intensity blending systems. Typical low intensity blending systems include tumble blenders (wide range of sizes), V-cone blender, ribbon blender, cement mixer, drum roller, or paint shaker for small lots. The same equipment can be used to mix pellets and powder. However, pellets and powder are more likely to separate when transporting the blend or loading it to a feed or extruder hopper after the blending is complete. The powder can flow between the pellets; consequently, at the beginning of an extrusion run the product may be rich in the powder component, while at the end of the extrusion run the product may be rich in the pellet component. One method to minimize this separation is to coat the pellets with a sm...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface

- Chapter 1: Extrusion Process

- Chapter 2: Extruder Safety

- Chapter 3: Single Screw Extruder: Equipment

- Chapter 4: Plastic Behavior in the Extruder

- Chapter 5: Screw Design

- Chapter 6: Processing Conditions

- Chapter 7: Scale Up

- Chapter 8: Shear Rates, Pressure Drops, and Other Extruder Calculations

- Chapter 9: Twin Screw Extrusion Process

- Chapter 10: Extruder Safety

- Chapter 11: Twin Screw Extruder Equipment

- Chapter 12: Plastic Behavior in Twin Screw Extruders

- Chapter 13: Screw Design

- Chapter 14: Processing Conditions

- Chapter 15: Applications

- Chapter 16: Scale-Up

- Chapter 17: Shear Rate, Pressure Drop, and Other Extruder Calculations

- Chapter 18: Polymer Overview and Definitions

- Chapter 19: Polymer Structure

- Chapter 20: Polymer Rheology

- Chapter 21: Testing Properties

- Chapter 22: Processing Recommendations for Various Resin Systems

- Chapter 23: Problem Solving

- Chapter 24: Five Step Problem Solving Process

- Chapter 25: Design of Experiments

- Chapter 26: Quality

- Chapter 27: Troubleshooting Mechanical Extrusion Problems

- Chapter 28: Troubleshooting Extrusion Product Problems

- Chapter 29: Troubleshooting Sheet Extrusion

- Chapter 30: Troubleshooting Cast Film

- Chapter 31: Troubleshooting Blown Film

- Chapter 32: Troubleshooting Profile and Pipe

- Chapter 33: Feed Systems

- Chapter 34: Drying

- Chapter 35: Screen Changers

- Chapter 36: Gear Pumps

- Chapter 37: Granulators

- Chapter 38: Chillers and Heaters

- Chapter 39: Screw Cleaning and Purge Compounds

- Chapter 40: Coextrusion Applications

- Chapter 41: Feedblocks and Dies

- Chapter 42: Polymer Selection for Coextrusion

- Chapter 43: Troubleshooting Coextrusion

- Chapter 44: Compounding

- Chapter 45: Sheet and Cast Film

- Chapter 46: Blown Film

- Chapter 47: Extrusion Coating and Lamination

- Chapter 48: Wire and Cable Coating

- Chapter 49: Profile Extrusion

- Chapter 50: Pipe and Tubing Extrusion

- Chapter 51: Monofilament

- Chapter 52: Extrusion Blow Molding

- Chapter 53: Foam Extrusion

- Chapter 54: Solid Stock Shapes

- Chapter 55: Reprocessing

- Glossary

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Extrusion by Harold F. Giles Jr,Eldridge M. Mount III,John R. Wagner Jr.,John R. Wagner, Jr. in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.