The Safety Relief Valve Handbook

Design and Use of Process Safety Valves to ASME and International Codes and Standards

- 326 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

The Safety Relief Valve Handbook

Design and Use of Process Safety Valves to ASME and International Codes and Standards

About this book

The Safety Valve Handbook is a professional reference for design, process, instrumentation, plant and maintenance engineers who work with fluid flow and transportation systems in the process industries, which covers the chemical, oil and gas, water, paper and pulp, food and bio products and energy sectors.It meets the need of engineers who have responsibilities for specifying, installing, inspecting or maintaining safety valves and flow control systems.It will also be an important reference for process safety and loss prevention engineers, environmental engineers, and plant and process designers who need to understand the operation of safety valves in a wider equipment or plant design context.- No other publication is dedicated to safety valves or to the extensive codes and standards that govern their installation and use. A single source means users save time in searching for specific information about safety valves- The Safety Valve Handbook contains all of the vital technical and standards information relating to safety valves used in the process industry for positive pressure applications.- Explains technical issues of safety valve operation in detail, including identification of benefits and pitfalls of current valve technologies- Enables informed and creative decision making in the selection and use of safety valves- The Handbook is unique in addressing both US and European codes: - covers all devices subject to the ASME VIII and European PED (pressure equipment directive) codes;- covers the safety valve recommendations of the API (American Petroleum Institute);- covers the safety valve recommendations of the European Normalisation Committees;- covers the latest NACE and ATEX codes;- enables readers to interpret and understand codes in practice- Extensive and detailed illustrations and graphics provide clear guidance and explanation of technical material, in order to help users of a wide range of experience and background (as those in this field tend to have) to understand these devices and their applications- Covers calculating valves for two-phase flow according to the new Omega 9 method and highlights the safety difference between this and the traditional method- Covers selection and new testing method for cryogenic applications (LNG) for which there are currently no codes available and which is a booming industry worldwide- Provides full explanation of the principles of different valve types available on the market, providing a selection guide for safety of the process and economic cost- Extensive glossary and terminology to aid readers' ability to understand documentation, literature, maintenance and operating manuals- Accompanying website provides an online valve selection and codes guide.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

|

| Figure 1.1 Denis Papin |

|

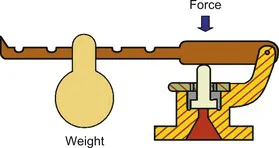

| Figure 1.2 Early 20th century-type weight-loaded Safety Relief Valve |

|

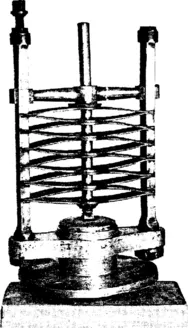

| Figure 1.3 First open-ended spring-operated Safety Relief Valve |

Table of contents

- Cover image

- Table of Contents

- Copyright

- Preface

- Acknowledgements

- Chapter 1. History

- Chapter 2. Overpressure Protection

- Chapter 3. Terminology

- Chapter 4. Codes and Standards

- Chapter 5. Design Fundamentals

- Chapter 6. Installation

- Chapter 7. Sizing and Selection

- Chapter 8. Noise

- Chapter 9. Safety Relief Valve Selection

- Chapter 10. Maintenance and Testing

- Chapter 11. Cryogenic Applications

- Chapter 12. Specifying Safety Relief Valves

- Chapter 13. Non-conformance of Existing Pressure Relief Systems

- Appendix Section: Relevant Tables and References

- Further Reading

- Index