eBook - ePub

Plastic Product Material and Process Selection Handbook

- 618 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Plastic Product Material and Process Selection Handbook

About this book

This book is for people involved in working with plastic material and plastic fabricating processes. The information and data in this book are provided as a comparative guide to help in understanding the performance of plastics and in making the decisions that must be made when developing a logical approach to fabricating plastic products to meet performance requirements at the lowest costs. It is formatted to allow for easy reader access and this care has been translated into the individual chapter constructions and index. This book makes very clear the behaviour of the 35,000 different plastics with the different behaviours of the hundreds of processes. Products reviewed range from toys to medical devices, to cars, to boats, to underwater devices, containers, springs, pipes, aircraft and spacecraft. The reader's product to be designed and/or fabricated can be directly or indirectly related to plastic materials, fabricating processes and/or product design reviews in this book.*Essential for people involved in working with plastic material and plastic fabricating processes *Will help readers understand the performance of plastics *Helps readers to make decisions which meet performance requirements and to keep costs low

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

INTRODUCTION

Overview

The growth of the plastic industry for over a century has been spectacular evolving into today’s routine to sophisticated high performance products. Examples of these products include packaging, building and construction, electrical and electronic, appliance, automotive, aircraft, and practically all markets worldwide. The plastic industry is the fourth largest industry in USA providing 1.5 million jobs. Because of the wide range of products meeting different performance/cost requirements and the large number of materials (35,000) used with different processes, material and process selection can become quite complex if not properly approached as reviewed in this book.

Plastic selection ultimately depends upon the performance criteria of the product that usually includes aesthetics and cost effectiveness. Analyzing how a material is expected to perform with respect to requirements such as mechanical space, electrical, and chemical requirements combined with time and temperature can be essential to the selection process. The design engineer translates product requirements into material properties. Characteristics and properties of materials that correlate with known performances are referred to as engineering properties. They include such properties as tensile strength and modulus of elasticity, impact, hardness, chemical resistance, flammability, stress crack resistance, and temperature tolerance. Other important considerations encompass such factors as optical clarity, gloss, UV stability, and weatherability.1, 248, 482

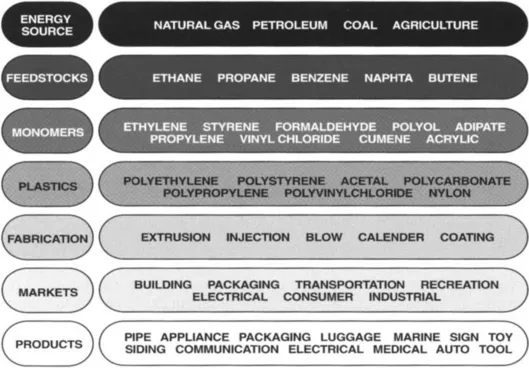

It would be difficult to imagine the modern world without plastics. Today they are an integral part of everyone’s life-style, with products varying from commonplace domestic to sophisticated scientific products.451 As a matter of fact, many of the technical wonders we take for granted would be impossible without versatile, economical plastics. The information in this book reviews the World of Plastics from plastic materials-to-processes that influence product designs that continue to generate the growth of plastics worldwideFigure 1.1).

Figure 1.1 Overview of the plastic industries from source to products that includes plastics and fabrication processes (courtesy of Plastics FALLO)

There have been a number of paradigm shifts in the plastic business model due to market changes. Gone are the days of just buying plastic and fabricating. Now industries want these associated with design collaboration, numerical analysis and virtual prototyping, global specifications, shorter technology life-cycle factors, quick market introduction windows, and product stewardship such as dematerialization and multiple life cycles. Expectations are higher for plastic materials and processes as well. Metals-to-plastic conversions, micro-molded parts, reinforced structural parts, shielded housings, thermoplastic elastomer applications, and parts for harsh environments are making use of a variety of developed plastics and filler systems.

Plastics are a worldwide, multibillion-dollar industry in which a steady flow of new plastic materials, new fabrication processes, new design concepts, and new market demands have caused rapid and tremendous growth. The profound impact of plastics to people worldwide and in all industries worldwide includes the plastics’ industry intelligent practical application that range from chemistry to engineering principles established in the past centuries.1, 482 These materials utilize the versatility and vast array of inherent plastic properties as well as highspeed/low-energy processing techniques. The result has been the development of cost-effective products used worldwide that in turn continue to have exceptional benefits for people and industries worldwide.

Plastics are now among the nations and world’s most widely used materials, having surpassed steel on a volume basis in 1983. With the start of this century, plastics surpassed steel even on a weight basis.1 These figures do not include the two major and important materials consumed, namely wood and construction or nonmetallic earthen (stone, clay, concrete, glass, etc.). Volume-wise wood and construction materials each are possibly about 70 billion ft3 (2 billion m3). Each represents about 45% of the total consumption of all materials. The remaining 10% include other materials with plastics being the largest. Plastic materials and products cover the entire spectrum of the world’s economy, so that their fortunes are not tied to any particular business segment. Designers are in a good position to benefit in a wide variety of markets: packaging,52 building and construction, electronics and electrical, furniture, apparel, appliances, agriculture, housewares, luggage, transportation, medicine and health care, recreation, and so on.

Classifying plastic

Plastics are a family of materials such as ceramics and metals. The family of plastics is classified several ways. The two major classifications are thermoplastics (TPs) and thermosets (TSs). Over 90wt% of all plastics used are TPs. The TPs and TSs in turn are classified as commodity or engineering plastics (CP and EP). Commodities such as PEs, PVCs, PPs, and PSs account for over two-thirds of plastic sales. Engineering plastics are characterized with meeting higher and/or improved performances such as heat resistance, impact strength, and the ability to be molded to high-precision standards. Examples are polycarbonate (PC representing at least 50wt% of all EPs), nylon, acetal, etc. Most of the thermoset plastics, as well as reinforced thermoplastics and thermoset plastics, are of the engineering type. Historically, as more competition and/or production occur for certain engineering plastics, their costs go down and they become commodity plastics. Half a century ago the dividing line costwise was about $0. 15/lb; now it is above $1.00/lb.

There are different types of plastics that are usually identified by their composition and/or performance. As an example there are virgin plastics. They are plastic materials that have not been subjected to any fabricating process. NEAT polymers identify plastics with Nothing Else Added To. They are true virgin polymers since they do not contain additives, fillers, etc. They are very rarely used. Plastic materials to be processed are in the form of pellets, granules, flakes, powders, flocks, liquids, etc. Of the 35,000 types available worldwide there are about 200 basic types or families that are commercially recognized with less than 20 that are popularly used. Examples of these plastics are shown in Table 1.1.

Table 1.1

Examples of major plastic families

| Acetal (POM) | Polyetherketone (PEK) |

| Acrylics | Polyetheretherketone (PEEK) |

| Polyacrylonitrile (PAN) | Polyetherimide (PEI) |

| Polymethylmethacrylate (PMMA) | Polyimide (PI) |

| Acrylonitrile butadiene styrene (ABS) | Thermoplastic PI |

| Alkyd | Thermoset PI |

| Allyls | Polymethylmethacrylate (acrylic) (PMMA) |

| Diallyl isophthalate (DAIP) | Polyolefins (PO) |

| Diallyl phthalate (DAP) | Chlorinated PE (CPE) |

| Aminos | Cross-linked PE(XLPE) |

| Melamine formaldehyde (MF) | High-density PE(HDPE) |

| Urea formaldehyde (UF) | Ionomer |

| Cellulosics | Linear LDPE(LLDPE) |

| Cellulose acetate (CA) | Low-density PE (LDPE) |

| Cellulose acetate butyrate (CAB) | Polyallomer |

| Cellulose acetate propionate (CAP) | ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- List of figures

- List of tables

- Preface, acknowledgement

- ACKNOWLEDGEMENT

- About the authors

- Chapter 1: INTRODUCTION

- Chapter 2: PLASTIC PROPERTY

- Chapter 3: FABRICATING PRODUCT

- Chapter 4: INJECTION MOLDING

- Chapter 5: EXTRUSION

- Chapter 6: BLOW MOLDING

- Chapter 7: THERMOFORMING

- Chapter 8: FOAMING

- Chapter 9: CALENDERING

- Chapter 10: COATING

- Chapter 11: CASTING

- Chapter 12: REACTION INJECTION MOLDING

- Chapter 13: ROTATIONAL MOLDING

- Chapter 14: COMPRESSION MOLDING

- Chapter 15: REINFORCED PLASTIC

- Chapter 16: OTHER PROCESSES

- Chapter 17: MOLD AND DIE TOOLING

- Chapter 18: AUXILIARY EQUIPMENT

- Chapter 19: SUMMARY

- REFERENCES

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Plastic Product Material and Process Selection Handbook by Dominick V Rosato,Donald V Rosato,Matthew v Rosato in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.