eBook - ePub

Fatigue Testing and Analysis

Theory and Practice

- 416 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Fatigue Testing and Analysis: Theory and Practice presents the latest, proven techniques for fatigue data acquisition, data analysis, and test planning and practice. More specifically, it covers the most comprehensive methods to capture the component load, to characterize the scatter of product fatigue resistance and loading, to perform the fatigue damage assessment of a product, and to develop an accelerated life test plan for reliability target demonstration. This book is most useful for test and design engineers in the ground vehicle industry.

Fatigue Testing and Analysis introduces the methods to account for variability of loads and statistical fatigue properties that are useful for further probabilistic fatigue analysis. The text incorporates and demonstrates approaches that account for randomness of loading and materials, and covers the applications and demonstrations of both linear and double-linear damage rules. The reader will benefit from summaries of load transducer designs and data acquisition techniques, applications of both linear and non-linear damage rules and methods, and techniques to determine the statistical fatigue properties for the nominal stress-life and the local strain-life methods.

- Covers the useful techniques for component load measurement and data acquisition, fatigue properties determination, fatigue analysis, and accelerated life test criteria development, and, most importantly, test plans for reliability demonstrations

- Written from a practical point of view, based on the authors' industrial and academic experience in automotive engineering design

- Extensive practical examples are used to illustrate the main concepts in all chapters

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 TRANSDUCERS AND DATA ACQUISITION

1.1 INTRODUCTION

This chapter addresses the sensors, sensing methods, measurement systems, data acquisition, and data interpretation used in the experimental work that leads to fatigue life prediction. A large portion of the chapter is focused on the strain gage as a transducer. Accurate measurement of strain, from which the stress can be determined, is one of the most significant predictors of fatigue life. Prediction of fatigue life often requires the experimental measurement of localized loads, the frequency of the load occurrence, the statistical variability of the load, and the number of cycles a part will experience at any given load. A variety of methods may be used to predict the fatigue life by applying either a linear or weighted response to the measured parameters.

Experimental measurements are made to determine the minimum and maximum values of the load over a time period adequate to establish the repetition rate. If the part is of complex shape, such that the strain levels cannot be easily or accurately predicted from the loads, strain gages will need to be applied to the component in critical areas. Measurements for temperature, number of temperature cycles per unit time, and rate of temperature rise may be included. Fatigue life prediction is based on knowledge of both the number of cycles the part will experience at any given stress level during that life cycle and other influential environmental and use factors. Section 1.2 begins with a review of surface strain measurement, which can be used to predict stresses and ultimately lead to accurate fatigue life prediction. One of the most commonly accepted methods of measuring strain is the resistive strain gage.

1.2 STRAIN GAGE FUNDAMENTALS

Modern strain gages are resistive devices that experimentally evaluate the load or the strain an object experiences. In any resistance transducer, the resistance (R) measured in ohms is material and geometry dependent. Resistivity of the material (ρ) is expressed as resistance per unit length × area, with cross-sectional area (A) along the length of the material (L) making up the geometry. Resistance increases with length and decreases with cross-sectional area for a material of constant resistivity. Some sample resistivities (μohms-cm2/cm) at 20°C are as follows:

Aluminum: 2.828

Copper: 1.724

Constantan: 4.9

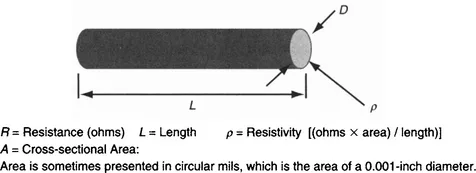

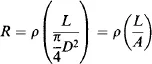

In Figure 1.1, a simple wire of a given length (L), resistivity (ρ), and cross-sectional area (A) has a resistance (R) as shown in Equation 1.2.1:

FIGURE 1.1 A simple resistance wire.

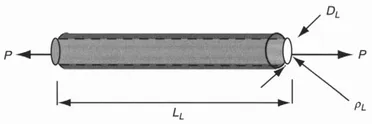

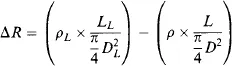

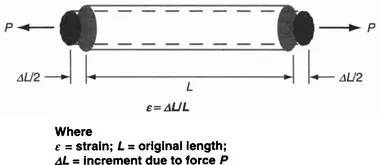

If the wire experiences a mechanical load (P) along its length, as shown in Figure 1.2, all three parameters (L, ρ, A) change, and, as a result, the end-to-end resistance of the wire changes:

FIGURE 1.2 A resistance wire under mechanical load.

The resistance change that occurs in a wire under mechanical load makes it possible to use a wire to measure small dimensional changes that occur because of a change in component loading. The concept of strain (ε), as it relates to the mechanical behavior of loaded components, is the change in length (ΔL) the component experiences divided by the original component length (L), as shown in Figure 1.3:

FIGURE 1.3 A simple wire as a strain sensor.

It is possible, with proper bonding of a wire to a structure, to accurately measure the change in length that occurs in the bonded length of the wire. This is the underlying principle of the strain gage. In a strain gage, as shown in Figure 1.4, the gage grid physically changes length when the material to which it is bonded changes length. In a strain gage, the change in resistance occurs when the conductor is stretched or compressed. The change in resistance (ΔR) is due to the change in length of the conductor, the change in cross-sectional area of the conductor, and the change in resistivity (Δρ) due to mechanical st...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- PREFACE

- ABOUT THE AUTHORS

- Chapter 1: TRANSDUCERS AND DATA ACQUISITION

- Chapter 2: FATIGUE DAMAGE THEORIES

- Chapter 3: CYCLE COUNTING TECHNIQUES

- Chapter 4: STRESS-BASED FATIGUE ANALYSIS AND DESIGN

- Chapter 5: STRAIN-BASED FATIGUE ANALYSIS AND DESIGN

- Chapter 6: FRACTURE MECHANICS and FATIGUE CRACK PROPAGATION

- Chapter 7: FATIGUE OF SPOT WELDS

- Chapter 8: DEVELOPMENT OF ACCELERATED LIFE TEST CRITERIA

- Chapter 9: RELIABILITY DEMONSTRATION TESTING

- Chapter 10: FATIGUE ANALYSIS IN THE FREQUENCY DOMAIN

- INDEX

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Fatigue Testing and Analysis by Yung-Li Lee,Jwo Pan,Richard Hathaway,Mark Barkey in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.