- 640 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This practical reference provides in-depth information required to understand and properly estimate compressor capabilities and to select the proper designs. Engineers and students will gain a thorough understanding of compression principles, equipment, applications, selection, sizing, installation, and maintenance. The many examples clearly illustrate key aspects to help readers understand the "real world" of compressor technology.Compressors: Selection and Sizing, third edition is completely updated with new API standards. Additions requested by readers include a new section on diaphragm compressors in the reciprocating compressors chapter, and a new section on rotor dynamics stability in the chapter on diaphragm compressors.The latest technology is presented in the areas of efficiency, 3-D geometry, electronics, CAD, and the use of plant computers. The critical chapter on negotiating the purchase of a compressor now reflects current industry practices for preparing detailed specifications, bid evaluations, engineering reviews, and installation. A key chapter compares the reliability of various types of compressors.

- Everything you need to select the right compressor for your specific application

- Practical information on compression principles, equipment, applications, selection, sizing, installation, and maintenance

- New sections on diaphragm compressors and an introduction to rotor dynamics stability

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Overview

Introduction

A compressor is a device used to increase the pressure of a compressible fluid. The inlet pressure level can be any value from a deep vacuum to a high positive pressure. The discharge pressure can range from subatmospheric levels to high values in the tens of thousands of pounds per square inch. The inlet and outlet pressures are related, corresponding with the type of compressor and its configuration. The fluid can be any compressible fluid, either gas or vapor, and can have a wide molecular weight range. Recorded molecular weights of compressed gases range from 2 for hydrogen to 352 for uranium hexafluoride. Applications of compressed gas vary from consumer products, such as home refrigerators, to large complex petrochemical plant installations.

The compressors to be covered in this book are those using mechanical motion to effect the compression. These types of compressors are commonly used in the process and gas transport/distribution industries. A partial list of these industries includes chemical, petrochemical, refinery, pulp and paper, and utilities. A few typical applications are air separation, vapor extraction, refrigeration, steam recompression, and process and plant air.

Compression Methods

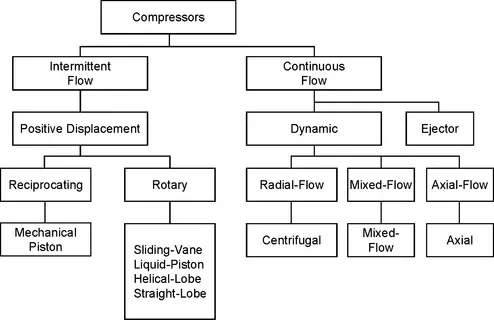

Compressors have numerous forms, their exact configurations being based on the application. For comparison, the different types of compressors can be subdivided into two broad groups based on the compression mode, either intermittent or continuous. The intermittent mode of compression is cyclic in nature: A specific quantity of gas is ingested by the compressor, acted upon, and discharged before the cycle is repeated. In the continuous compression mode the gas is moved into the compressor, acted upon, moved through the compressor, and discharged without interruption of the flow at any point in the process.

Compressors using the intermittent compression mode are referred to as positive displacement compressors, of which there are two distinct types: reciprocating and rotary. Continuous-mode compressors are also characterized by two fundamental types: dynamic and ejector.

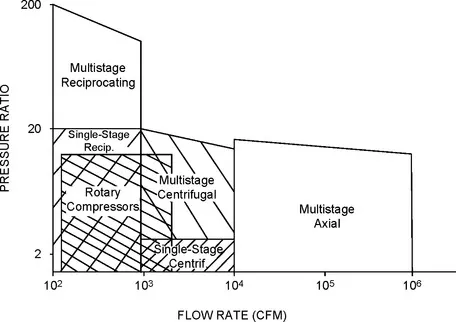

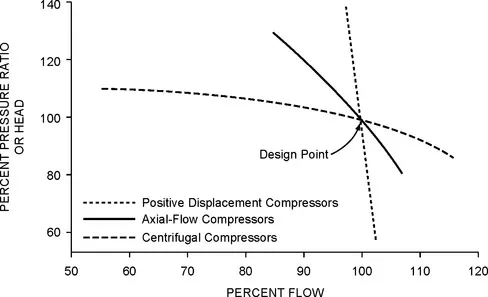

This chapter will give a brief overview of each of the different compressors commonly used in the process industries. Subsequent chapters will then cover each of the mechanical types in depth. (The ejector type, which does not use mechanical action, will not be covered in detail.) Figure 1-1 diagrams the relationship of the various compressors by type. Figure 1-2 shows the typical application range of each compressor, and Figure 1-3 compares the characteristic curves of the dynamic compressors (axial and centrifugal) with positive displacement compressors.

Figure 1-1 Chart of compressor types.

Figure 1-2 Typical application ranges of compressor types.

Figure 1-3 General performance curve for axial-flow, centrifugal, and positive displacement compressors.

Intermittent Mode Compressors

Reciprocating Piston Compressors

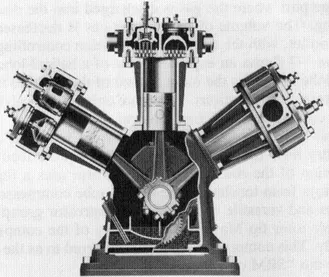

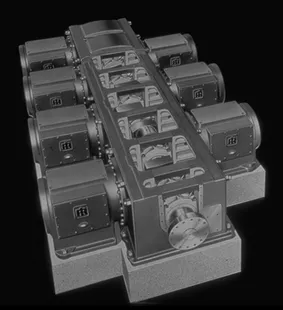

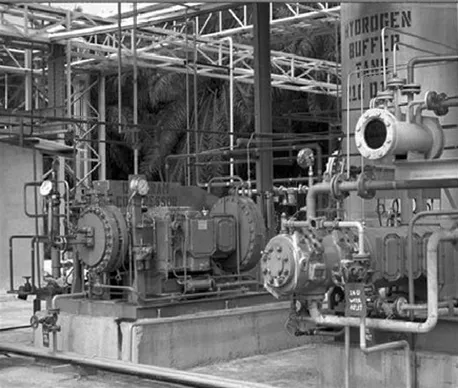

The reciprocating compressor is probably the best known and the most widely used of all compressors. It consists of a mechanical arrangement in which reciprocating motion is transmitted to a piston that is free to move in a cylinder. The displacing action of the piston, together with the inlet valve or valves, causes a quantity of gas to enter the cylinder where it is in turn compressed and discharged. Action of the discharge valve or valves prevents the backflow of gas from the discharge line into the compressor during the next intake cycle. When the compression takes place on one side of the piston only, the compressor is said to be single-acting. The compressor is double-acting when compression takes place on each side of the piston. Configurations consist of a single cylinder or multiple cylinders on a frame. When a single cylinder is used or when multiple cylinders on a common frame are connected in parallel, the arrangement is referred to as a single-stage compressor. When multiple cylinders on a common frame are connected in series, usually through a cooler, the arrangement is referred to as a multistage compressor. Figures 1-4 and 1-5 illustrate typical reciprocating compressor arrangements, beginning with the single-stage and ending with a more complex multistage.

Figure 1-4 A three-stage single-acting reciprocating compressor.

(Courtesy of Ingersoll Rand.)

Figure 1-5 Cutaway of the frame end of a large multistage reciprocating compressor.

(Courtesy of Dresser-Rand.)

The reciprocating compressor is generally in the lower flow end of the compressor spectrum. Inlet flows range from less than 100 to approximately 10,000 cfm per cylinder. It is particularly well suited for high pressure service. One of the highest pressure applications is at a discharge pressure of 40,000 psi. Above an approximately 1.5-to-1 pressure ratio, the reciprocating compressor is one of the most efficient of all the compressor types.

Reciprocating Diaphragm Compressors

In the reciprocating compressor family, there is a piece of equipment that is not as well known as the piston type reciprocating compressor. This compressor is the diaphragm compressor—used primarily in lower flow applications—but is capable of high pressure services. It consists of a crankcase assembly very much like the piston compressor, which in fact it is identical to, including a piston. The piston moves oil rather than gas, using the oil to move a diaphragm pack that in turn moves the gas. By the nature of the head construction, the diaphragm does not have any leakage to the atmosphere. Also, there is no leakage toward the inside to contaminate the process gas. Because relatively little power is used, most units are belt-driven by a motor. A single-stage diaphragm compressor is shown in Figure 1-6. The two-stage compressor can be arranged in various configurations similar to the piston compressor, that is, in an L arrangement or an opposed arrangement. Figure 1-7 is an example of an opposed arranged diaphragm compressor.

Figure 1-6 Vertical single-stage diaphragm compressor.

(Courtesy Burton Corblin.)

Figure 1-7 Horizontally opposed two-stage diaphragm compressor.

(Courtesy Burton Corblin.)

Rotary Compressors

The rotary compressor portion of the positive displacement family is made up of several compressor configurations. The features these compressors have in common are:

1. They impart energy to the gas being compressed by way of an input shaft moving a single or multiple rotating element.

2. They perform the compression in an intermittent mode.

3. They do not use inlet and discharge valves.

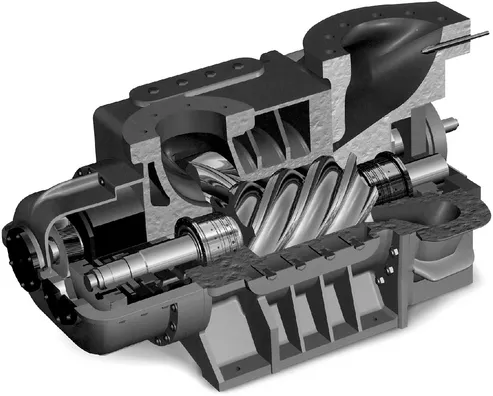

Helical and spiral-lobe compressors are generally similar and use two intermeshing helical or spiral lobes to compress gas between the lobes and the rotor chamber of the casing. The compression cycle begins as the open part of the spiral form of the rotors passes over the inlet port and traps a quantity of gas. The gas is moved axially along the rotor to the discharge port where the gas is discharged into the discharge nozzle of the casing. The volume of the trapped gas is decreased as it moves toward the outlet, with the relative port location controlling the pressure ratio. Figure 1-8 shows a cutaway of an oil-free helical-lobe compressor. The spiral-lobe version is the more limited of the two and is used only in lower pressure applications. Therefore, only the helical-lobe compressor will be covered in depth in this book (see Chapter 4).

Figure 1-8 Cutaway of an oil-free helical-lobe rotary compressor.

(Co...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- Acknowledgments

- About the Author

- Chapter 1: Overview

- Chapter 2: Basic Relationships

- Chapter 3: Reciprocating Compressors

- Chapter 4: Rotary Compressors

- Chapter 5: Centrifugal Compressors

- Chapter 6: Axial Compressors

- Chapter 7: Drivers

- Chapter 8: Accessories

- Chapter 9: Dynamics

- Chapter 10: Testing

- Chapter 11: Negotiation and Purchasing

- Chapter 12: Reliability Issues

- Appendix A: Conversion Factors

- Appendix B: Pressure-Enthalpy and Compressibility

- Appendix c: Physical Constants of Hydrocarbons

- Appendix D: Labyrinth and Carbon Ring Seal Leakage Calculations

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Compressors by Royce N. Brown in PDF and/or ePUB format, as well as other popular books in Design & Industrial Design. We have over one million books available in our catalogue for you to explore.