- 368 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Improving Changeover Performance

About this book

Improving Changeover Performance is essential reading for managers, engineers and improvement practitioners working in manufacturing industries. It will also prove invaluable to original equipment manufacturers and postgraduates and academic researchers alike.

Increasing importance is being placed on responsive, flexible manufacture in multi-product industrial environments. The ability to changeover production facilities both quickly and to a high standard is a key component of just-in-time and lean manufacturing paradigms, which are increasingly being adopted as businesses strive to compete in today's volatile and congested markets.

Currently industry frequently adopts the SMED (Single Minute Exchange of Die) system, a well-established shop floor method to improve changeovers. This book takes a major step beyond the SMED system, by describing in much greater detail than hitherto the potential role of engineering design, of both substantive and non-substantive nature, to enhance changeovers. It also clearly sets out what better changeover performance can contribute to business competitiveness, and describes the many pitfalls that an improvement initiative can face.

- Provides overall methodology for changeover improvementIncorporates design into SMED system

- Recommended by the IMechE Journal of Engineering Manufacture

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

The importance of good changeover performance in multi-product manufacturing environments is becoming ever more widely understood. Certainly, the academic community has devoted considerable attention to this topic. There is also a greater awareness of changeover issues within manufacturing industry. This applies to industries as diverse as presswork, plastic moulding, pharmaceutical, foodstuffs, printing and domestic consumables. Many other industries can also be nominated, including those that are concerned primarily with assembly operations. Whereas there was a particular early focus upon changeover improvement within the presswork industry, this is no longer the case. It is now recognized that any business where a range of products is to be manufactured on non-dedicated equipment should be conscious of its changeover capability.

Awareness of changeover issues should include an awareness of what better change-overs might contribute to business performance. The rewards can often be substantial. One option is simply to devote any time that is saved to increasing production volume. At one site, for just one line, we estimated that this could contribute an additional profit of nearly £1 million per annum. Yet in many respects this is a crude exploitation of an improved manufacturing capability. Often it is more advantageous to exploit this new capability instead by increasing the frequency with which change-overs are conducted. Products are manufactured in smaller batches. Many potential benefits are possible by manufacturing this way, not least of which are those that arise by being more flexible, or more responsive to customer requirements. At the same time, for example, significant inventory reductions might also be achieved. Using a very basic analysis, halving changeover time while at the same time doubling the number of changeovers that take place can potentially permit a 50 per cent inventory reduction.

Much of the current attention to changeover issues can be attributed to Shigeo Shingo’s pioneering work. His changeover book A Revolution in Manufacturing: The ‘SMED’ System1 is rightly recognized as a reference text. Yet it is now nearly 20 years since Shingo’s changeover work became widely known. Our book aims to update Shingo’s work. We argue that emphasizing procedural improvements to shopfloor activity, as largely described by Shingo’s single minute exchange of die (SMED) methodology,2 can be re-examined in the light of what has been learnt over these last two decades. We suggest that a wider, more comprehensive approach to changeover improvement can be adopted; an approach that addresses diverse issues that can otherwise significantly diminish the results that an improvement initiative achieves.

1.1 Changeover and modern manufacturing practice

It is now generally agreed that the philosophy of mass manufacture, which has long been at the heart of volume manufacturing practice, has become obsolete.3–6 The limitations of mass manufacturing have become apparent as competitive performance criteria have broadened, where the prominence of price and cost efficiency, which have been a primary justification of mass manufacture, have declined.7–9 Increasingly a business now has to compete simultaneously on price, product quality, product differentiation, delivery performance, and rapid product development.10–12 These objectives must be achieved additionally without compromising overall productivity, while still retaining excellent control of costs and staying abreast of technological advance.13,14

Traditional mass manufacturing techniques, in which businesses typically employ a rigid process technology, are ill-matched to accommodate all these demands.15 Instead a responsive, multi-product, small-batch, low-inventory, flexible manufacturing capability is required to enable an organization to compete successfully in today’s volatile and congested markets. A change towards such a manufacturing capability has gradually come about since the early 1980s as JIT (Just-In-Time) manufacturing techniques have increasingly been adopted.16,17 Subsequently, JIT manufacturing techniques have largely become embodied in ‘world-class’ manufacturing18–20 and ‘lean’/‘agile’ manufacturing.21,22 A highly prominent component of these modern manufacturing philosophies is the need for better changeover performance.23–27

1.2 The aims of the book

This book is uniquely concerned with changeover performance – what it is, what it can contribute and how to improve it. We will assess what constitutes a changeover. We will consider the potential strategic impact of improved changeover performance. We will also consider in detail how to set about achieving significantly faster, higher-quality changeovers. Examples of the approach we advocate, drawn from case studies, will be provided. We will investigate the many pitfalls or difficulties that a changeover improvement initiative can face.

It has frequently been asserted in the past that better changeovers should be achieved principally by continuous, incremental improvement activity, conducted by a shopfloor team and concentrating upon changing existing work practices and procedures. Although this approach has prevailed when seeking retrospective improvement, this need not represent the only possible approach, nor indeed, in many cases, the best.28 For example, there are factors that can influence the outcome of an initiative that are likely to be beyond the influence of a shopfloor team. Potential limitations to team activity, among many other considerations, should be understood. A comprehensive understanding of what an improvement initiative is likely to involve should be in place before the initiative gets underway. An initiative should involve more than simply selecting a production process to work upon, engaging shopfloor personnel, seeking to maximize ‘external time’ effort (see below) and setting arbitrary improvement targets.

A major theme of this book will be the potential contribution of design to achieve better changeovers, by physically changing the existing manufacturing system. We will investigate how design may be applied either as an alternative or complementary strategy to seeking improvement by organizational change. This is a topic that, to date, has received little attention. Design for changeover may occur retrospectively, or may be applied to new equipment as supplied by the original equipment manufacturer. This book is targeted primarily at those seeking to improve their manufacturing operations but, by setting out generic design rules, it can also help original equipment manufacturers to respond to customers who are increasingly demanding changeover-proficiency in the specification of their new equipment.29–34

1.3 The structure of the book

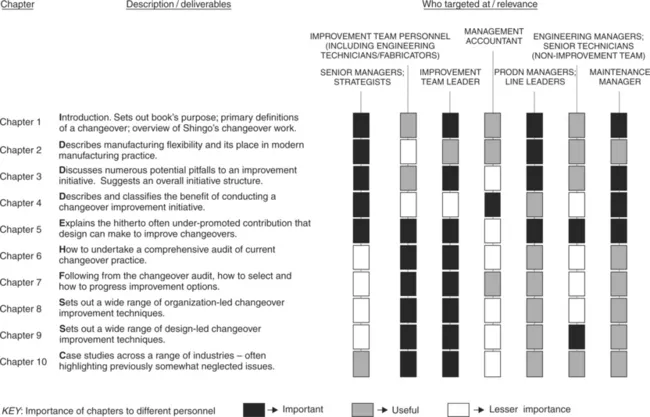

The book is structured for use by manufacturing industry. Different chapters will be of particular interest to managers and to production personnel. In general, the earlier chapters are aimed at senior business managers, where the strategic requirement for rapid changeover will be investigated, and our overall methodology for changeover improvement will be described. Later chapters are more focused on achieving improvement in detail, addressing topics that are of particular relevance to improvement practitioners – those who are responsible for effecting change on the shopfloor. Throughout the book we shall propose different tools and documentation (as later summarized by Figure 7.15) that might assist the improvement effort.

Apart from those directly concerned with manufacturing operations, our discussion of design issues should be of use to original equipment manufacturers. In addition, by highlighting how the disciplines of changeover and maintenance can significantly impinge upon one another, we believe that sections of our text will also be useful to maintenance staff.

Finally, we have also attempted to write a book that is relevant for academic purposes. To do so without unduly disrupting the text for industrial readers we have provided our references – and, often, a brief explanation of the point we are drawing from them – at the end of each chapter. Nevertheless, it is still sometimes necessary to describe our thinking in detail in the main body of the text, particularly concerning the development of the different tools that we propose. A summary of the topics of each chapter is presented in Figure 1.1.

Figure 1.1 The content and likely relevance of different chapters

1.4 Definitions

What constitutes a changeover needs to be defined if changeover activity is to be investigated. Some important definitions are presented below that will be applied throughout this book. Other definitions will be introduced...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- Acknowledgements

- Chapter 1: Introduction

- Chapter 2: Manufacturing flexibility

- Chapter 3: Addressing diverse changeover issues: An overall methodology for changeover improvement

- Chapter 4: Financial benefit analysis

- Chapter 5: The role of design

- Chapter 6: Shopfloor issues: Changeover auditing

- Chapter 7: Shopfloor issues: Develop an operational strategy; Set local targets; Implement; Monitor

- Chapter 8: Organization-led improvement techniques

- Chapter 9: Design-led improvement techniques

- Chapter 10: Case studies

- Changeover terms

- Acronyms

- Changeover audit sheet

- Suggested classifications

- Improvement option assessment

- Changeover improvement work

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Improving Changeover Performance by S. Culley,A. Mileham,R. McIntosh,G. Owen in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.