- 328 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Analysis and Design Principles of MEMS Devices

About this book

Sensors and actuators are now part of our everyday life and appear in many appliances, such as cars, vending machines and washing machines. MEMS (Micro Electro Mechanical Systems) are micro systems consisting of micro mechanical sensors, actuators and micro electronic circuits. A variety of MEMS devices have been developed and many mass produced, but the information on these is widely dispersed in the literature. This book presents the analysis and design principles of MEMS devices. The information is comprehensive, focusing on microdynamics, such as the mechanics of beam and diaphragm structures, air damping and its effect on the motion of mechanical structures. Using practical examples, the author examines problems associated with analysis and design, and solutions are included at the back of the book. The ideal advanced level textbook for graduates, Analysis and Design Principles of MEMS Devices is a suitable source of reference for researchers and engineers in the field.* Presents the analysis and design principles of MEMS devices more systematically than ever before.* Includes the theories essential for the analysis and design of MEMS includes the dynamics of micro mechanical structures* A problem section is included at the end of each chapter with answers provided at the end of the book.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Introduction to MEMS Devices

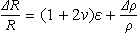

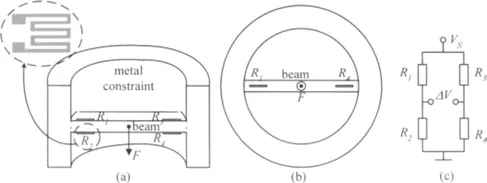

§1.1 Piezoresistive Pressure Sensor

(1) Metal Strain Gauge

(2) Strain Gauge Sensors

(3) Piezoresistance Effect

§1.1.2 Piezoresistive Pressure Transducer

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface

- Summary

- Chapter 1: Introduction to MEMS Devices

- Chapter 2: Mechanics of Beam and Diaphragm Structures

- Chapter 3: Air Damping

- Chapter 4: Electrostatic Actuation

- Chapter 5: Capacitive Sensing and Effects of Electrical Excitation

- Chapter 6: Piezoresistive sensing

- Answers to the Problems

- Subject Index