- 856 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

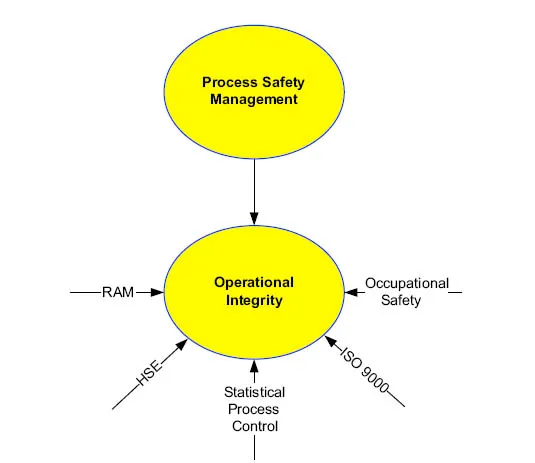

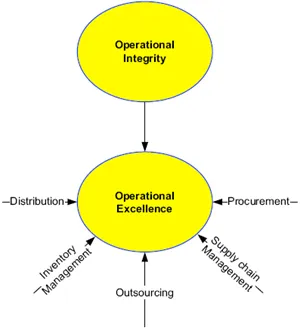

In the last twenty years considerable progress has been made in process safety, particularly in regard to regulatory compliance. Many companies are now looking to go beyond mere compliance; they are expanding their process safety management (PSM) programs to improve performance not just in safety, but also in environmental compliance, quaility control and overall profitability. Techniques and principles are illustrated with numerous examples from chemical plants, refineries, transportation, pipelines and offshore oil and gas.This book helps executives, managers and technical professionals achieve not only their current PSM goals, but also to make the transition to a broader operational integrity strategy. The book focuses on the energy and process industries- from refineries, to pipelines, chemical plants, transportation, alternative energy and offshore facilities. The techniques described in the book can also be applied to a wide range of non-process industries.The book is both thorough and practical. It discusses theoretical principles in a wide variety of areas such as management of change, risk analysis and incident investigation, and then goes on to show how these principles work in practice, either in the design office or in an opperating facility.- Learn how to develop process safety, operational integrity and operational excellence programs- Go beyond traditional hazards analysis and risk management programs to explore a company's entire range of procedures, processes and mangement issues- Understand how to develop a culture of process safety and operational excellence that goes beyond simple rule complience

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER

1

Operational integrity

management

INTRODUCTION

OPERATIONAL INTEGRITY/EXCELLENCE

PROCESS SAFETY MANAGEMENT

| 1 | Employee Participation |

| 2 | Process Safety Information |

| 3 | Process Hazards Analysis |

| 4 | Operating Procedures |

| 5 | Training |

| 6 | Contractors |

| 7 | Prestartup Safety Rev... |

Table of contents

- Cover

- Title

- Copyright

- Preface

- Chapter 1: Operational integrity management

- Chapter 2: Culture and employee involvement

- Chapter 3: Hazards identification

- Chapter 4: Consequence and likelihood analysis

- Chapter 5: Technical information and industry standards

- Chapter 6: Asset integrity

- Chapter 7: Reliability, Availability and Maintainability

- Chapter 8: Operations, maintenance, and safety

- Chapter 9: Operating procedures

- Chapter 10: Training and competence

- Chapter 11: Emergency management and security

- Chapter 12: Incident investigation and root cause analysis

- Chapter 13: Management of change

- Chapter 14: Audits and assessments

- Chapter 15: Process safety management compliance

- Chapter 16: Managing a risk and reliability program

- References

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app