- 231 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Blacksmith's Manual Illustrated

About this book

This vintage book contains a practical treatise on the common methods of production for blacksmiths, apprentice blacksmiths, engineers, and others. Profusely illustrated and full of helpful tips, this volume provides a elementary introduction to the tools and techniques of the workshop, and is highly recommended for those with little previous experience. Contents include: "Forges for Hearths", "Cast-Iron Forge", "Brick Forge", "Hearths", "Pot Fire", "Tools", "Anvils", "Hand Hammer", "Tongs", "Hand Tools", "Anvil Tools", "Clippers, etc.", "Anvil Swages", "Small Anvil", "Angle Bar Tools", "Cutters", "Side Set Tools", "Radius Tools", "Spring Swages", etc. Many vintage books such as this are becoming increasingly scarce and expensive. We are republishing "Blacksmith's Manual Illustrated" now in an affordable, high-quality edition complete with a specially commissioned new introduction on blacksmithing.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

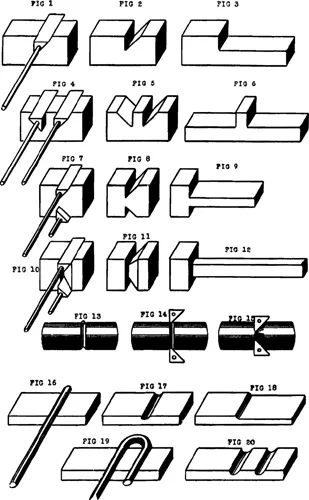

MISCELLANEOUS EXAMPLES OF FORGED WORK IN DIFFERENT STAGES. PLATE 41

SIDE SETS

PLATE 41 illustrates side sets being used for making various forgings.

FIG. 1 illustrates the side set in use.

FIG. 2 illustrates the result before being drawn down.

FIG. 3 illustrates the result after being drawn down.

FIG. 4 illustrates two side sets in use.

FIG. 5 illustrates the results before being drawn down.

FIG. 6 illustrates the results after being drawn down.

FIG. 7 illustrates how to get a smaller section into the centre of the bar, by using two side sets one above the other.

FIG. 8 illustrates the results before being drawn down.

FIG. 9 illustrates the results after being drawn down.

FIG. 10 illustrates the bar being side set on the four sides.

FIG. 11 illustrates the result before being drawn down.

FIG. 12 illustrates the result after being drawn down.

To side set a round bar it is advisable to recess it when hot by placing a small diameter bar on top, and keep turning the large bar until it is practically fullered to the depth of the small diameter bar, as shown in FIG. 13.

FIG. 14 illustrates the placing of the side sets in the recess and continually turning the bar.

FIG. 15 illustrates the results.

FIG. 16 illustrates the method that is adopted when fullering a flat bar, by means of a round bar being hammered in.

FIG. 17 illustrates the result before being drawn down.

FIG. 18 illustrates the result after being drawn down.

FIG. 19 illustrates a round bar doubled to the required width and hammered in.

FIG. 20 illustrates the result similar to FIG. 6.

SIDE SETS.

PLATE 41

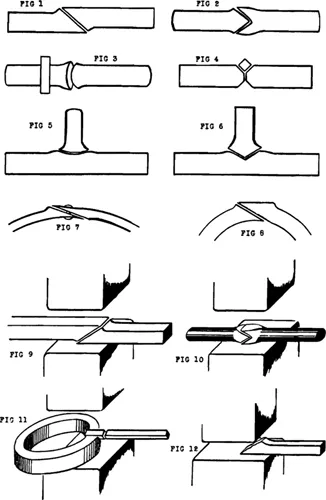

MISCELLANEOUS EXAMPLES OF FORGED WORK IN DIFFERENT STAGES. PLATE 42

WELDING METHODS

Welding is the combining together of two pieces of iron or mild steel. This is done by heating both pieces to a plastic state, then hammering one into the other so as to form one solid bar. During the heating process it is necessary that the healed iron should be kept from coming in contact with the air-blast, the reason for this being that heated iron absorbs oxygen, thus forming a scale and preventing a good weld. Sand is a very good flux when welding mild steel. It melts and covers the heated surface, thus protecting it from oxidation and therefore is of great assistance in making a good weld.

FIG. 1 illustrates a scarf weld commonly used.

FIG. 2 illustrates a fork and wedge weld used for welding steel into iron.

FIG. 3 illustrates a butt weld which is used when one end is close up to a shoulder.

FIG. 4 illustrates a V-weld suitable for heavy rings.

FIG. 5 illustrates a stud weld, i.e. a round bar welded into a square bar forming a T-piece.

FIG. 6 illustrates another stud weld.

FIG. 7 illustrates a rivet weld suitable when making large hoops.

FIG. 8 illustrates a scarf weld suitable for small rings.

FIG. 9 is showing FIG. 1 welding under the hammer.

FIG. 10 is showing FIG. 2 welding under the hammer.

FIG. 11 is showing FIG. 4 welding under the hammer.

FIG. 12 illustrates a method of scarfing under the steam hammer.

WELDING METHODS.

PLATE 42

MISCELLANEOUS EXAMPLES OF FORGED WORK IN DIFFERENT STAGES. PLATE 43

JUMPING

PLATE 43 gives a few examples of jumping. This process is used to increase the diameter, width, or thickness, at the same time reducing the length.

FIG. 1 shows a heavy flat bar turned up at each end used as an apparatus for jumping. The method of using this bar is shown. By heating the bar to be jumped, and then bending it, it can be placed between the two uprights and hammered where it is hot, thus jumping it to the required length. If the uprights are too far apart to enable the bar to be jumped between t...

Table of contents

- Cover

- Title

- Contents

- Forges or Hearths

- Anvil tools, Hand tools, and power Hammer tools

- Estimation of lengths of material

- Miscellaneous Forgings

- Hardening

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Blacksmith's Manual Illustrated by J. W. Lillico in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.