Industrial Automation

Learn the current and leading-edge research on SCADA security

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Industrial Automation

Learn the current and leading-edge research on SCADA security

About this book

Explores the components of automation Key Features

- The book provides basic concepts of industrial automation

- It is beneficial for engineering students having interest in the field of automation

- The unique feature of this book is the inclusion of multiple-choice questions to help prepare students for competitive exams and interviews

- It covers the roles of SCADA and PLC in automation

Description

Automation is a process to perform controlled activities with minimal human assistance. A lot of research is being carried out in this field. Students are also opting for research and studies in automation. The objective of this book is to explain the role of industrial automation. This book will help engineering students to understand the basic concepts of industrial automation. The unique feature of this book is the inclusion of multiple-choice questions to help prepare students for competitive exams and interviews. Automation has grown into a vast field and this book will be helpful to understand it comprehensively. What Will You Learn

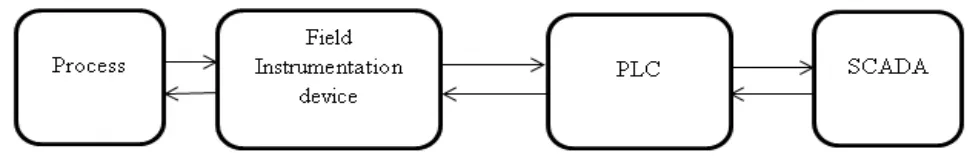

- SCADA and its application in Industrial Automation

- Supervisory and Control Functions

- SCADA Communication Network

- Human Machine Interface

- SCADA in EMS

- Programmable Logic Controller

- Automation Software

- Field Instrumentation Device

- Utility Information System

Who This Book Is For

Engineering students having research interests in the field of automation. Table of Contents

- SCADA in Industrial Automation

- Supervisory and Control Functions

- SCADA Communication Network

- Human Machine Interface

- SCADA in EMS

- Programmable Logic Controller

- Applications of SCADA

- Automation Software

- Field Instrumentation Device

- Utility Information System

- About the Author

Mr.Vikalp Joshi

holds a B.Tech(Instrumentation) degree from University Science Instrumentation Center, H.N.B.G.U, Srinagar (Garhwal), and M.Tech (Instrumentation and Control) from Graphic Era University, Dehradun. He has two years of industrial experience in the field of industrial automation in packaging industries and around five years of teaching experience in reputed engineering institutes and central university. Currently, he is working as an automation engineer at Shivansh controls, Dehradun, Uttarakhand. He has published many research papers on national and international journals. His area of interest covers Industrial Automation, Industrial instrumentation, and Process Control Instrumentation. Dr. Manoj Singh Adhikari

received his B.Tech. degree in Electronics and Communication Engineering from Dev Bhoomi Institute of Technology, Dehradun, India, in 2010 and M.Tech. degree in Digital Signal Processing Engineering from the G. B. Pant Institute of Engineering and Technology (formerly known as G. B. Pant Engineering College), Pauri Garhwal, India, in 2013. He received his Ph. D. in Jan. 2019 from the same institution.Currently, he is working as an Assistant Professor in Lovely Professional University, Phagwara, Punjab. His research interests are simulation and modeling of power semiconductor devices. He has published more than ten research papers in reputed journals/conferences like IET, IEEE, ELSEVIER, Springer, and so on. He is serving as a reviewer for IEEE Transactions on Electron Devices, AEÜ - International Journal of Electronics & Communications, and Springer. Dr. Raju Patel

is working as an Assistant Professor in Department of Electronics & Communications Engineering, MBM Engineering College, Jodhpur, Rajasthan, India. He received his Ph.D. and M.Tech. (Specialization - VLSI Design) degrees from Malaviya National Institute of Technology, Jaipur, India, in 2014 and 2018 respectively. Bachelor of Engineering degree in Electronics & Communication Engineering from S.B.C.E.T., Jaipur, University of Rajasthan, 2007. He has a teaching and research experience for over eleven years. His research interests include design, simulation, fabrication, and characterization of Film Bulk Acoustic Resonator as a RF filter and gas sensing applications. Dr. Rajesh Singh

is currently associated with Lovely Professional University as a Professor with more than fifteen years of experience in academics. He has been awarded as gold medalist in M.Tech and honors in his B.E. His area of expertise includes embedded systems, robotics, wireless sensor networks, and Internet of Things. He has organized and conducted a number of workshops, summer internships, and expert lectures for students as well as faculty. He has twenty three patents in his account. He has published around hundred research papers in referred journals/conferences.

Under his mentorship, students have participated in national/international competitions including the Texas competition in Delhi and Laureate award of excellence in robotics engineering in Spain. He has been awarded with "certificate of appreciation" and "Best Researcher award- 2017" twice in last four years from University of Petroleum and Energy Studies for exemplary work. He got "certificate of appreciation" for mentoring the projects submitted to Texas Instruments Innovation challenge India design contest, from Texas Instruments, in 2015.He has been honored with young investigator award at the International Conference on Science and Information in 2012. He has published fifteen books in the area of Embedded Systems and Internet of Things with reputed publishers. He is an editor to special issues published by AISC book series, Springer with title "Intelligent Communication, Control and Devices"-2017 and 2018. Dr. Anita Gehlot

is currently associated with Lovely Professional University as an Associate Professor with more than ten years of experience in academics.She has twenty patents in her account. She has published more than fifty research papers in referred journals and conference. She has organized a number of workshops, summer internships, and expert lectures for students. She has been awarded with "certificate of appreciation" from University of Petroleum and Energy Studies for exemplary work. She has published fifteen books in the area of Embedded Systems and Internet of Things with reputed publishers. She is aneditor to a special issue published by AISC book series, Springer with title "Intelligent Communication, Control and Devices-2018".

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

CHAPTER 1

SCADA in Industrial Automation

Objectives

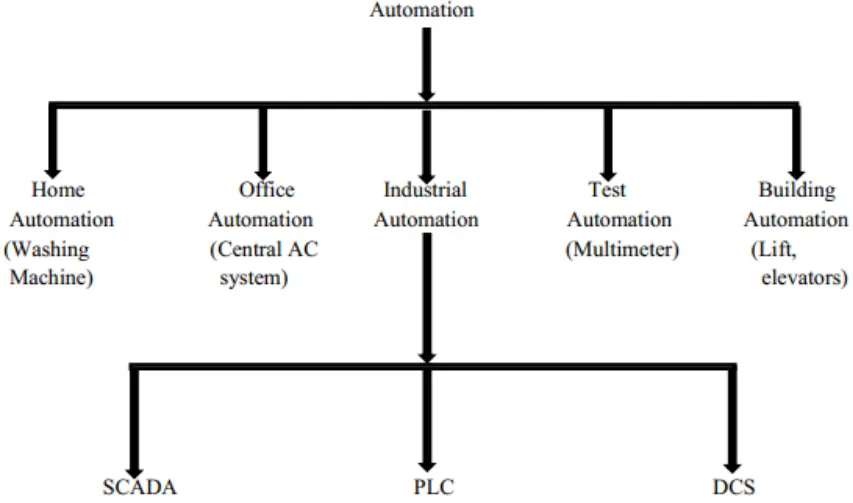

- Introduction and classification of Automation

- Benefits of automation system

- Role of SCADA in Automation industry

- SCADA Architectures

- SCADA Generations

- “Regulatory Function” in SCADA

1.1 Automation

- Capture the measurement and control command for particular operation

- Transmute specific command into controlling action for particular operation

- Automation Manufacturing systems

- Computerization of the manufacturing and maintenance systems

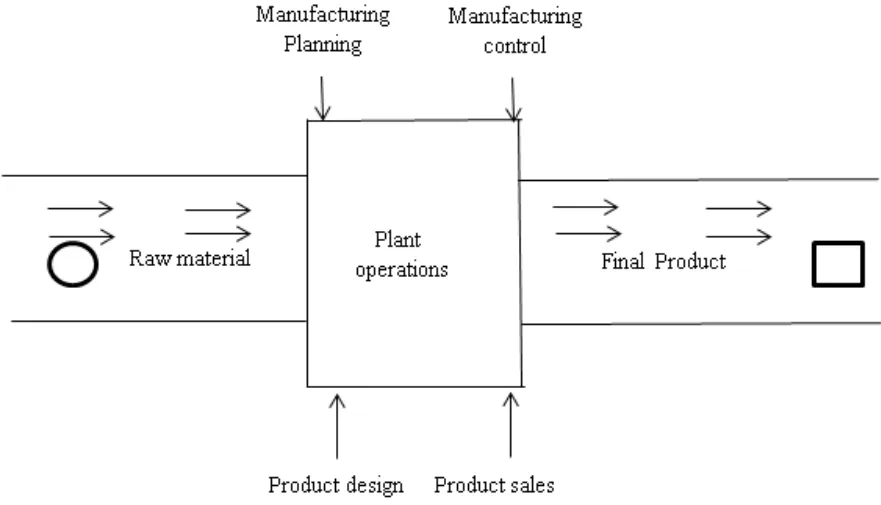

1.1.1 Automation Manufacturing Systems

- Transfer of raw material and manufacturing product into several different types of operation units

- The system is used to do material processing using the industrialized robots

- Automatic material control and packing systems

- Automatic inspection for quality purpose with high resolution sensors and cameras

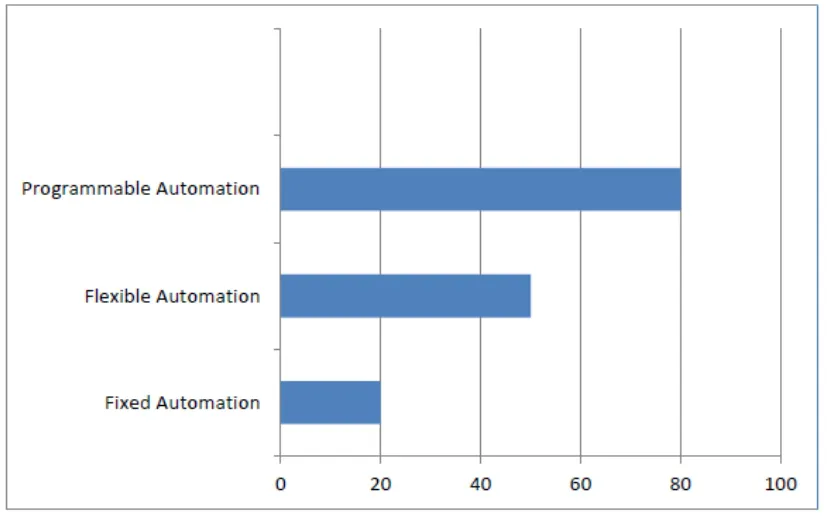

Types of Automation

- Fixed automation

- Programmable automation

- Flexible automation

- Simple structure and easy installation

- Initial investment of assembly machine is very high

- Variations of production rates with respect to quality of the final product

- Uncompromising in the acceptance of the product variety

- Preliminary cost of general purpose device is high

- Lesser production rate in comparison with the fixed automation

- Suppleness to deal with the deviations and changes in the product pattern

- Most appropriate for the batch production

- Time taken to change the machine tools has reduced

- Continuous production of the final products

- Suppleness to deal with final product design deviations

1.1.2 Computerization of Manufacturing Maintenance System

1.1.3 Classification of Automation

1.1.4 Automation Functions

| Company level | Automation function |

| Business control management | Sales and cost analysis of the product, audit of various operations |

| Production control management | Capacity of the machine, handling capability of the operator, and analysis of the process output |

| Process control management | Measurement and control of regulatory variables in and out of the process |

1.1.5 Benefits of Automation System

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Preface

- About the Authors

- Table of Contents

- 1. Scada in Industrial Automation

- 2. Supervisory and Control Functions

- 3. SCADA Communication Network

- 4. Human Machine Interface

- 5. Scada in Ems

- 6. Programmable Logic Controller

- 7. Applications of Scada

- 8. Automation Software

- 9. Field Instrumentation Device

- 10. Utility Information System