![]()

Chapter 1

Introduction

The computational fluid dynamics (CFD) technique is already well established and many books can be found describing this technique in great detail. Implementing the technique for modeling the spray-drying process, however, is not a trivial endeavor. The engineer or modeler will have to understand how to effectively numerically capture the important airflow characteristics, droplet drying behavior, and the particles transport phenomenon typically occurring within the drying chamber. This is precisely the aim of this book: how to numerically capture the important physical phenomena within a spray-drying process using the CFD technique. Therefore, this book is not a basic treatment of the CFD technique. It is also not a discussion fundamentally focusing on the physics of spray drying. The key word here is “numerical capture” and it is the aim of this book to link the physical phenomena involved with the numerical aspect on how they can be represented numerically in a CFD simulation. The book will also include numerical strategies in effectively capturing these phenomena numerically. These strategies are collated from research work in this area and from CFD industrial consultation particularly to the dairy industry.

It will be noted later on that some parts of this book will make reference to the FLUENT software, which is part of the ANSYS workbench package. These elements were included mainly to highlight how some of the concepts discussed in this work are available in commercial CFD codes. To the industrial engineer, this may provide a reference on the accessibility of some of the numerical capabilities and the degree of work required to implement them. The author is by no means affiliated with ANSYS and this information is provided solely due to the familiarity of the author. There are numerous commercial CFD packages and open source codes available for the industry.

This book will be of interest to engineers and scientists interested in setting up their own CFD model of a spray-drying process. Apart from teaching the reader on how to set up their models, the discussion in this book will help the reader to identify the capabilities (or the uncertainty) of the CFD technique for spray drying. This will be particularly useful when interpreting the results from such simulations. Although basic knowledge of the spray-drying process is not necessary in reading this book, some exposure to or experience in the CFD technique will allow better appreciation and application of the strategies outlined in this book.

1.1 Why Do We Need CFD Simulation of Spray Drying?

Spray drying is widely used in the food, pharmaceutical, and detergent industry to produce dry powders. This is indeed a complex process and is highly nonlinear owing to the combination of droplet or particles transport within the drying chamber and the simultaneous moisture removal process. The control of these simultaneous phenomena, culminating in the different drying history experienced by the droplet or particle, is the key in ensuring reliable operation of a spray dryer. Therefore, in contrast to the traditional approach of treating the spray dryer as a black box, CFD simulation is now often used to provide a better understanding and visualization of the process. Such understanding can be very useful in designing new spray dryers or troubleshooting existing operations.

1.2 Components of CFD Simulation of Spray Drying

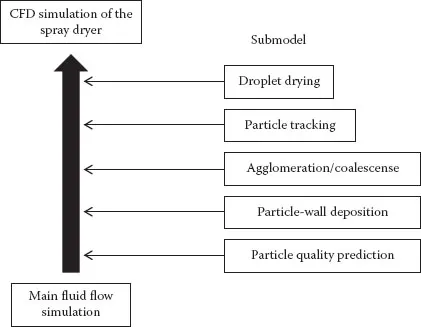

The core of a CFD simulation of a spray dryer, in fact for any CFD simulation, is the airflow or fluid flow prediction framework. This is numerically undertaken by solving the momentum equation of the air corresponding to the geometrical shape of the spray dryer and the operating conditions for the spray dryer, the boundary conditions of the simulations. Building on top of the fluid flow prediction, submodels are then incorporated into the larger CFD framework. These submodels are key numerical components, which distinguish the spray-drying simulation from the conventional fluid-only simulations. These submodels are shown in Figure 1.1.

All the submodels shown are important as they represent different physical aspects of spray drying. If possible, and for higher level of accuracy, it will be desirable to include all these submodels into the CFD simulation. It should be noted that each of these submodels introduces a certain level of uncertainty as they are normally developed independently and validated for specific applications, which may not be spray-drying applications. At the time of preparing this book, not all the submodels are fully well established or validated. The Lagrangian particle-tracking submodel is typically used to track and predict how particles move in the spray chamber. As part of the Lagrangian particle tracking, atomization submodels are then used to define the initial and boundary conditions of the particle tracking. The initial condition of the particle should correspond to the atomization process of the droplet and the atomization submodel accounts for this. If a particle impacts the wall during the simulation, the particle deposition submodel is then used to determine the boundary condition of the outcome of the particle–wall interaction. The key challenge is how to account for particle stickiness or adhesive characteristics in the deposition submodel. Once the movement of the droplet or particle is tracked in the simulation, the single droplet drying submodel will then be used to account for heat and mass transfer to and from the droplet. Development of this branch of submodel has attracted most of the attention in the development of spray-drying modeling as this forms the core of spray drying.

The above-mentioned submodels are commonly found and are “standard” requirement in all the spray-drying simulations reported. Some recent work has introduced the agglomeration submodel into the larger simulation framework. In comparison to the other submodels mentioned above, the agglomeration submodel is relatively more complex and it can be further broken down into several submodels combined to predict agglomeration of particles.

It will be noted that other quality development submodels are separated from the “core” submodels mentioned so far. This is because, in the current state of the models, the submodels are mainly used and implemented as a postprocessing step and do not feedback into the computation of the other submodels or the core fluid computation framework. Further development in these models may forge two-way couplings between these and the other submodels in the future, if required.

This book is organized based on individual components of a CFD simulation of spray drying as illustrated in Figure 1.1. Chapters 2 and 3 of this book focus on the core CFD airflow computation. The remaining chapters then focus on individual submodels. A theoretical framework is firstly given to the reader followed by important considerations when implementing these submodels numerically.

Figure 1.1 Components of a CFD simulation of spray drying.

These are the theoretical frameworks of a CFD simulation for spray drying. In most commercial CFD programs, the core airflow prediction and the Lagrangian particle tracking submodel are normally available as built-in features of the software. The other submodels may require additional coding and separate implementation into the commercial codes. For FLUENT, this refers to the use of the user-defined functions, whereas for CFX, this points to the use and implementation of the CCL codes.

![]()

Chapter 2

Basics of CFD

The aim of this section is to provide a brief overview of what a CFD simulation actually is. To put this into layman’s terms, when we solve a CFD model or undertake a CFD simulation, what are we solving for? For many engineers who have seen or been shown a CFD simulation visualization, a question that may arise might be: how was the flow field generated? This section aims to provide a brief explanation to answer this question. Most books on CFD will touch on the equations used in the model. This book, however, focuses on the concept and the overall idea of CFD. This will be particularly useful for engineers who have not undertaken an advanced course in fluid flow or numerical modeling. Therefore, the theoretical aspects or the equations involved will be covered only briefly. The theoretical aspects of fluid mechanics or transport phenomena essential in CFD are covered in typical undergraduate or in advanced engineering courses. Even if one is familiar with the theoretical aspects, this chapter may give a “practical” aspect of the theory. The focus is mainly to familiarize the readers with the jargon and the basic concept behind CFD simulations, which will be essential for further reading in this book. For simplicity, only a discussion of a two-dimensional aspect of CFD simulations will be presented; however...