eBook - ePub

Recycled Ceramics in Sustainable Concrete

Properties and Performance

- 282 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Recycled Ceramics in Sustainable Concrete

Properties and Performance

About this book

Recycled Ceramics in Sustainable Concrete: Properties and Performance explores the use of novel waste materials in the construction industry as sustainable and environmentally friendly alternatives to traditional cement production technologies. It specifically focuses on using waste ceramics as a binder and aggregate replacement for concrete.

- Includes a lifecycle assessment

- Describes recycling of ceramic tile waste as fine and coarse aggregate replacement

- Discusses microstructure performance of sustainable concrete

- Evaluates performance of sustainable concrete exposed to elevated temperatures and corrosives

Written for materials, chemical, and civil engineers as well as others who develop construction materials, this book provides readers with a thorough understanding of the merits of using waste ceramics to produce sustainable concrete.

.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Recycled Ceramics in Sustainable Concrete by Kwok Wei Shah,Ghasan Fahim Huseien in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

1 Recycling of Ceramic Wastes

Emerging Research and Opportunities

1.1 Introduction

To achieve a sustainable world, reducing carbon dioxide (CO2) emissions into the atmosphere is one of the important factors to be considered. The biggest producers of CO2 emissions are related to the construction industries, that is cement manufacturing, steel factories and transportation. Worldwide, around 5% of the total of CO2 emissions is contributed by the cement industry alone [1]. Therefore, partially replacing the weight of cement with pozzolanic wastes is one effective way to reduce the environmental impact of CO2 emissions from cement production [2]. Previously, natural pozzolanic wastes have been used as construction material due to their positive effects on mechanical properties and durability of mortar [3]. However, because of stringent environmental regulations, researchers have focused on using industrial waste as a pozzolanic material [4, 5]. Nowadays huge amounts of ceramic wastes are produced by the ceramic industries which cause environmental impact and landfill problems. World production of ceramic tiles was approximately 12.4 billion square metres in 2015 [6]; Malaysia manufactured 92 million square metres of ceramic in the same year and that is increasing by 2.2% each year [7]. It is estimated that 10–30% of total ceramic production goes as waste [8]. Most of this ceramic waste cannot be recycled and later creates disposal issues [9]. The use of ceramic waste in concrete contributes to cost and energy savings, ecological balance, and conservation of natural resources [10]. The large generation of ceramic waste with little utilization encouraged researchers to use it in mortar as cement replacement [11].

Since aggregates in concrete and mortar comprise about 60–75% of the total volume, any reduction in natural aggregate consumption will have significant impact on the environment. Besides the environmental constraints of stone pits, noise, dust, vibrations, and the impact on the countryside, the consumption of a non-renewable materials tends to considerably limit their exploitation. Consequently, alternative materials such as construction and demolition wastes as well as other industrial by-products are increasingly being tested and used as sustainable natural aggregates substitutes [12]. The use of inorganic industrial waste in making concrete will lead to sustainable concrete design and a greener environment [13]. The need to develop concrete with non-conventional aggregates is highly needed for environmental as well as economic reasons. A review of earlier research showed that industrial waste and other wastes have been introduced in concrete making not only to improve the properties of concrete but also to reduce cost. The inclusion of recycled steel tyre fibres in concrete was found to avoid the opening of cracks and increase energy absorption [14]. In addition, structural lightweight concrete has been produced using palm oil shells waste [15] and demolished masonry waste [16] as aggregates. Other research revealed that an improvement in the modulus of elasticity of concrete was observed with partial replacement of crushed stone coarse aggregates with crushed vitrified soil aggregates [17].

The ceramic industry is known to generate large amounts of calcined clay waste each year. Reusing this waste in concrete could be a win–win situation. Ay and Ünal [18] reported that the use of ceramic waste as pozzolanic material in different percentage as cement replacement shows better performance when the tile waste had been used as pozzolanic material by up to 30% of weight of cement. It was also reported that ceramic wastes are potentially suitable for replacement of Portland cement without detrimental effect on the compressive strength [9]. Other research showed that concrete containing 20% ceramic waste powder as cement replacement material reached 75% of compressive strength of the control specimen at 7 days of curing and increased the durability performance of concrete [19]. Research on the utilization of crushed ceramic waste as fine aggregates was conducted by Alves et al. [20] and it was reported that the concrete showed good strength properties. A study that was conducted on the effect of crushed ceramic and basaltic pumice used as fine aggregates showed better compressive strength in comparison to the control specimen [21]. A similar finding was also reported that compressive strength was unchanged when ceramic waste was used to partially replace conventional crushed stone coarse aggregates [22, 23]. This indicated that ceramic waste could be potentially transformed into useful coarse or fine aggregates. The properties of coarse and fine aggregates of ceramic waste are well within the range of the value of concrete-making aggregates. The properties of ceramic waste coarse aggregates concrete are not significantly different from those of conventional concrete [22]. Therefore, the use of ceramic wastes as coarse aggregates in concrete has increased because it has various advantages over other cementitious materials [24].

East Asia is one of the developing regions where the construction of many infrastructures is still ongoing and, consequently, requires a high demand of concrete that will affect the use of natural aggregates as resources. Therefore, the present work focuses on the recycle and reuse of industrial waste to produce new construction material. In this research, due to its abundant availability, ceramic waste was studied as a potential material for cement, coarse and fine aggregates replacements. Nowadays, the high demand for ordinary Portland cement (OPC) partly contributes to environmental pollution and the release of carbon dioxide gasses to the atmosphere. The excessive amount of carbon dioxide gas in the atmosphere can cause many problems not only to the environment but also to reinforced concrete structures. In addition, ceramic waste is not biodegradable and consumes a lot of landfill space. Finding new ways to recycle this waste in the construction of infrastructures can be useful to preserve natural resources and the environment. In order to evaluate the true potential of ceramic waste for new applications, as cement and aggregates replacements, a comprehensive and detailed study of the fundamental properties of the material is highly needed.

1.2 Environmental Problems of Cement

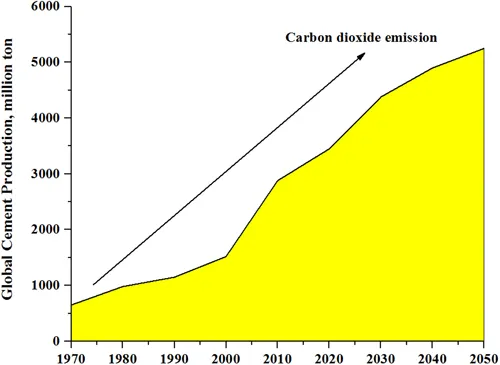

Universally, OPC has been continually exploited as a concrete binder and different building substances. Cement manufacturing is an intensive energy consumer and significantly affects climate change. The main issues related to the cement industry are the emission of carbon dioxide to the atmosphere and energy consumption that affect environmental health and safety. The cement industry consumes a large amount of natural resources that are not renewable. It is reported that 5–6% of carbon dioxide emission produced by human activities was contributed by the manufacture of cement [25]. Due to the implementation of the Kyoto Protocol in February 2005, countries all over the world have to reduce their greenhouse gas emissions. Therefore, one of the major challenges is to reduce the CO2 emissions from the cement manufacturing industries. Furthermore, according to the study done by Earth Institute of Colombia University, cement manufacturing as a single industry produced 5% of the total carbon dioxide emissions and cement production is growing 2.5% yearly. Around 0.8–1.3 tonnes of carbon dioxide is discharged for 1 tonne of cement manufacturing and about 0.8 tonnes of carbon dioxide is released for 1 tonne of cement clinker production [26]. In developing countries, especially China and India, the rise in cement production is causing a dramatic increase in the level of carbon dioxide as shown in Figure 1.1, which needs immediate action to find ways to reduce the usage of cement. With the increasing population, the demand of cement for construction industries is increasing and it is expected to increase until the year 2050. Therefore, by using blended cement or replacing some of the weight of cement with industrial waste that has cementitious properties can be an effective way to reduce pressure on the environment.

1.3 Concrete Durability Problems

The serviceability of construction materials has considerable economic significance, particularly with modern infrastructures and components. For urbanization, concrete materials that are greatly exploited must meet the requisites of standard codes of practice related to strength and durability [27]. For instance, poor planning, low capacity or overload, faulty material design and structures, incorrect construction practices or unsatisfactory maintenance, and lack of engineering knowledge can often diminish the service lifespan of concrete under operation [28]. In the construction industries, fast declination of concrete structures being a major setback necessitates additional improvement. Varieties of physical, chemical, thermal and biological processes are respon...

Table of contents

- Cover

- Half-Title

- Series

- Title

- Copyright

- Contents

- Preface

- Authors

- Chapter 1 Recycling of Ceramic Wastes: Emerging Research and Opportunities

- Chapter 2 Chemical, Physical, and Mineral Properties of Ceramic Wastes

- Chapter 3 Utilizing Ceramic Wastes in the Concrete Industry

- Chapter 4 Effects of Ceramic Waste on Durability Performance of Traditional Concrete

- Chapter 5 Properties of Ceramic Waste-Based Alkali-Activated Mortars

- Chapter 6 Bond Strength Performance of Alkali-Activated Mortars in Aggressive Environments

- Chapter 7 Ceramic Waste-Based Self-Compacting Alkali-Activated Concrete

- Chapter 8 Durability Performance of Ceramic Waste–Based Alkali-Activated Mortars

- Chapter 9 Performance Evaluation Alkali-Activated Mortar Exposed to Elevated Temperatures

- Chapter 10 Sustainability of Ceramic Waste in the Concrete Industry

- Chapter 11 Alkali-Activated Mortars Containing Ceramic Waste as Repair Material

- Chapter 12 Structural Applications of Alkali-Activated Concrete Containing Ceramic Waste

- Index