eBook - ePub

X-Ray Imaging

Fundamentals, Industrial Techniques and Applications

- 574 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

X-Ray Imaging

Fundamentals, Industrial Techniques and Applications

About this book

While books on the medical applications of x-ray imaging exist, there is not one currently available that focuses on industrial applications. Full of color images that show clear spectrometry and rich with applications, X-Ray Imaging fills the need for a comprehensive work on modern industrial x-ray imaging. It reviews the fundamental science of x-ray imaging and addresses equipment and system configuration. Useful to a broad range of radiation imaging practitioners, the book looks at the rapid development and deployment of digital x-ray imaging system.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access X-Ray Imaging by Harry E. Martz,Clint M. Logan,Daniel J. Schneberk,Peter J. Shull in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Electrical Engineering & Telecommunications. We have over one million books available in our catalogue for you to explore.

Information

Edition

1| 1 | Introduction to Nondestructive Evaluation |

In this opening chapter of this book, we explore the background of nondestructive evaluation (NDE) and describe how the technology has matured into a full participatory partner in design and manufacturing and has gone beyond to waste disposal and life cycle management. We present a brief overview of the major NDE techniques and technologies, which will give the reader a sense of how x-ray imaging fits into the larger world of NDE. We introduce the language and methods of evaluating the performance of NDE systems and close the chapter with a discussion of the similarities among and differences between industrial x-ray imaging and medical x-ray imaging.

After completion of this chapter the student will have learned

- A brief history of nondestructive evaluation (NDE), nondestructive testing (NDT), nondestructive characterization (NDC), nondestructive inspection (NDI), nonintrusive inspection (NII), and so forth

- The role of NDE throughout a product life cycle

- Ionizing and nonionizing radiation

- The technology and major applications of

- X-ray and γ-ray methods

- Optical interferometric methods

- Candling

- Optical fluorescence

- Thermal imaging

- Gigahertz–terahertz waves (microwaves and millimeter waves)

- Ultrasonic testing

- Acoustic emission

- Dye penetrant testing

- Magnetic particle inspection

- Leak testing using tracer gas

- Eddy current testing

- Performance measures and metrics

- How medical and industrial imaging compare and contrast

1.1A BRIEF HISTORY OF NDE, NDT, AND NDC

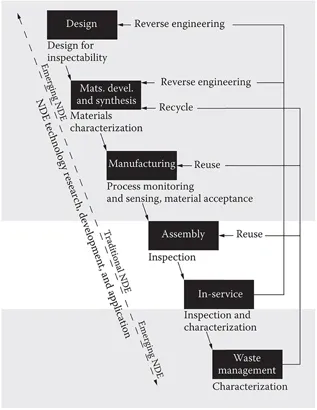

The inspection of materials and components, with the objective of locating and quantifying defects and degradation in material properties that would lead to failure, is essential to the safe utilization of engineering structures. Such inspections are thus an integral part of the science and technology needed to ensure product quality and reliability. A wide variety of noninvasive measurement techniques are employed, including ultrasonics, radiography, and electromagnetics (Shull 2002), which are familiar from other fields of noninvasive measurements such as medicine, geophysical prospecting, sonar, and radar. Depending on the manner of their utilization, inspection with such techniques is often referred to as NDT. NDT is what we refer to as traditional NDE in Figure 1.1. NDT or traditional NDE had been used only as an end-product (final assembly) or in-service inspection tool. More details on the terminology used in this field are contained in Panel 1.1.

FIGURE 1.1Nondestructive evaluation’s traditional and expanding role in the life cycle of a product.

PANEL 1.1Testing, Evaluation, and other Terms

Our scientific community utilizes several terms as identifiers of the technology and practice of nondestructive testing (NDT). There is no precise and widely agreed-upon distinction between these terms. We present here our sense of how the terms are used. We will attempt to follow these definitions in this book. NDT is the narrowest of these terms. It applies to a pass/fail test of a part or component. Historically, the term was applied when the situation was such that if a defect could be detected, then the part was rejected. Usually, only large defects could be detected, and part failure was likely in that event. When the NDT technology got better, it could detect small defects in every part. A decision was now necessary as to the life expectancy (or probability of failure over the service lifetime) of the part given the size distribution and location of defects. Now the word testing did not seem to convey the action, and NDE came into common usage. Recently, there has been greater effort at inspection of cargo and packages. For many of these situations, the technique has to be not only nondestructive but also nonintrusive. Thus, nonintrusive inspection (NII) has come into widespread use in this field.

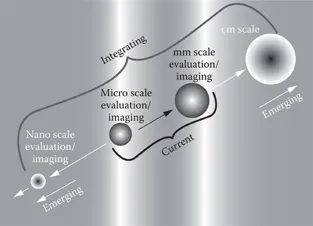

Much of the recent frontier work in NDE was directed toward smaller objects and higher spatial resolution, but cargo inspection and waste characterization push the boundaries for large objects and lower spatial resolution. (See Figure 1.2.)

FIGURE 1.2Just as with other fields, NDE needs to cover a very broad range of scale lengths. The main direction of change is toward smaller objects and finer spatial resolution. However, there are situations where larger objects and coarser spatial resolution is being developed, e.g., waste assay with resolution of about 6 cm.

NDC and quantitative nondestructive evaluation (QNDE) are similar terms indicating that more than defect characterization is taking place. For example, perhaps some continuous material variable is being measured, or a critical internal dimension is being evaluated.

NDT has been practiced for many decades. The technological advances that occurred during World War II and the subsequent defense effort spurred initial rapid developments in instrumentation. The primary purpose was the detection of macroscopic defects. As a part of safe-life design, it was intended that a structure should not develop macroscopic defects during its life, with the detection of such defects being a cause for removal of the component from service. This approach was generally satisfactory in the 1950s and 1960s, since the materials were most often utilized well below their ultimate yield strength and possessed a high resistance to crack propagation as well as a high fracture toughness (Buckley 1976). In response to the need to detect macroscopic defects, increasingly sophisticated techniques using ultrasonics, eddy currents, x-rays, dye penetrants, magnetic particles, and other forms of interrogating methods emerged.

The World Federation of NDE Centers claims that in the early 1970s, two events occurred that caused a major change (World Federation of NDE Centers 2015) in NDT:

The continued improvement of NDT technology, in particular its ability to detect small flaws, led to the unsatisfactory situation that more and more parts had to be rejected, even though the probability of failure had not changed. However, the discipline of fracture mechanics emerged, which enabled one to predict whether a crack of a given size would fail under a particular load if a material property, fracture toughness, were known. Other laws were developed to predict the rate of growth of cracks under cyclic loading (fatigue). This formed the basis for the new philosophy of ‘fail safe’ or ‘damage tolerant’ design. Components having known defects could continue in service as long as it could be established that those defects would not grow to a critical, failure-producing size.

Buckley corroborates this in his paper (Buckley 1976). This basic change in philosophy required the designer to assume the presence of an initial flaw in each critical manufactured structure and to design the structure such that the flaw would not grow to critical size during its intended service life. Thus, a new challenge was presented to the NDT community. Detection was not enough. One also needed to obtain quantitative information about flaw size to serve as an input to fracture mechanics–based predictions of life before service and remaining life in-service.

These concerns, which were felt particularly strongly in the defense, space, and nuclear power industries, led to the creation of a number of research programs directed toward high-value, high-consequence-of-failure components and assemblies around the world. About this time, the emergence of “quantitative” NDT became known as quantitative nondestructive evaluation (QNDE) or just NDE as a new discipline. The groups most active in the United States were the American Society for Nondestructive Testing (ASNT); Electric Power Research Institute (EPRI); American Welding Society; National Bureau of Standards (NBS, now named the National Institute for Standards and Technology [NIST]); Center for Nondestructive Evaluation (CNDE) at Iowa State University (growing out of a major research effort initiated at the Rockwell International Science Center); Center for Nondestructive Evaluation (CNDE) at Johns Hopkins University; and the NDE group at Lawrence Livermore National Laboratory (LLNL). Overseas were the Nondestructive Testing Centre Atomic Energy Establishment (England), Fraunhofer Institute for Nondestructive Testing (Germany), National Institute for Advanced Interdisciplinary Research (Japan), Russian Academy of Sciences, and similar organizations in a number of other countries. In the last few years, global security concerns have shifted NDE from weapons systems to NII of luggage and cargo. This is providing the next surge in technology development for NDE and NDC.

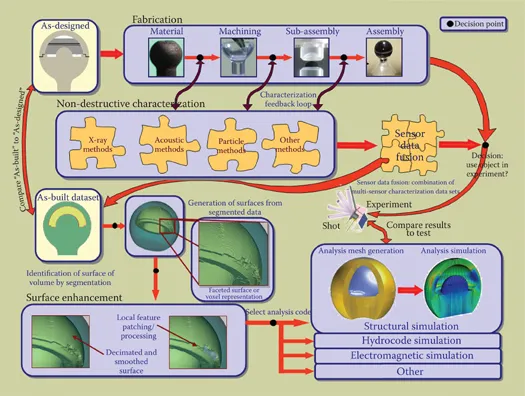

In the ensuing years, many important advances have been made. Quantitative theories have been developed to describe the interaction of the interrogating fields with flaws. Simulations incorporating these theories and results have been integrated with solid model descriptions of real-part geometries (we refer to this as as-built as opposed to as-designed modeling of the object) (Kokko et al. 2006) to simulate practical inspections (JCISE 2006). We illustrate in Figure 1.3 how, for example, as-built models are being used in the understanding of high-energy-density science (Brown and Martz 2006). These tools allow NDE to be considered, as a part of the design process, on equal footing with other failure-related science and engineering disciplines.

FIGURE 1.3Example of the use of NDE for the life cycle of a high-energy-density science target of dimensions of about millimeter extent.

Quantitative descriptions of NDE performance, such as the probability of detection* (POD), have become an integral part of statistical risk assessment (Olin and Meeker 1996). A good summary of this is given by Buckley in a paper, “The Future Economic Role of NDE” (Buckley 1976). Measurement procedures initially developed for metals have been extended to engineered materials, such as composites, in which anisotropy and inhomogeneity become important issues (see Panel 1.2). The rapid advances in digitization and computing capabilities have changed the types of instruments and algorithms that can be used in processing the resulting data (Grampp et al. 1997; Laugier 2007). High-spatial resolution imaging systems and the fusion of information from multiple measurement modalities in characterizing a flaw have emerged (Gros 1997; Kokko et al. 2006). An increasing interest is found not only in detecting, characterizing, and sizing defects, but also in characterizing the materials in which they reside (Kouris et al. 1982; Martz et al. 1991b; Lewis et al. 1992; Martz 1998; Aufderheide et al. 2007). Goals can range from the determination of fundamental microstructural characteristics such as grain size, porosity, and texture (preferred grain orientation) (Krautkramer and Krautkramer 1990; Nicoletti and Anderson 1997; Karacan ...

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Table of Contents

- Preface

- Acknowledgments

- Authors

- Chapter 1: Introduction to Nondestructive Evaluation

- Chapter 2: X-Ray History

- Chapter 3: The Role of X-Ray and γ-Ray Imaging

- Chapter 4: Physics of X-Ray and γ-Ray Sources

- Chapter 5: High-Energy (X-Ray and γ-Ray) Photon Interactions with Matter

- Chapter 6: Radiation Transport Simulation

- Chapter 7: Radiation Dosimetry, Safety, and Shielding

- Chapter 8: Radiation Sources

- Chapter 9: Radiation Detectors

- Chapter 10: Imaging System Components

- Chapter 11: Imaging-System Configurations

- Chapter 12: Digital Radiography

- Chapter 13: Computed Tomography

- Chapter 14: Image Quality

- Chapter 15: Special Techniques

- Chapter 16: Selected High-Energy Photon Applications

- Chapter 17: Neutron and Proton Imaging

- Glossary

- List of Notations

- References

- Index