- 191 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

The biggest competitive advantage an organization can achieve comes from the synergies created by employees skilled in enhancing organizational dynamics. The Seven Kata: Toyota Kata, TWI, and Lean Training supplies time-tested tools and advice to help readers adapt to changing conditions and outcompete their rivals. It explains why a mix of the ski

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Weapons for the Economic Warrior

1.1 Skills, Not Tools

Medieval swordsmen knew that their success in battle relied not only on how lethal their weapon was, but also how suitable their skill was. Toyota doesn’t rely on brilliant people as their weapon of profitability; Toyota relies on average people and teaches them the skills most suitable to continuously improve.1

This book will provide the reader with the seven weapons necessary to outcompete economic rivals. These weapons, or skills, provide the workforce with the ability to adapt to changing conditions, a hallmark of Lean. Like the seven swords depicted on the cover of this book, the seven skills promoted will require their own specialized techniques and proper application. For almost 30 years, Lean has been the enigmatic golden ring that far too many organizations have reached for but have failed to grasp. We believe this is due to management’s misapplication of some tools, and ignorance of the standard skills that all managers must practice daily.

Lean is not a set of tools to be implemented but rather a set of practiced skills that facilitate the modification of organizational culture. Our (Patrice Boutier’s) definition of a Lean culture may be long, but it is encapsulating: “…one that capitalizes on the entire workforce’s involvement in creative problem solving and continuous improvement, reaching beyond the competition by innovatively developing best practices.” A Lean culture is based on the standardized thinking skills that a workforce possesses. Only then can Lean tools be more adroitly used. An explanation distinguishing the known tools of Lean with these standard skills for Lean is in order.

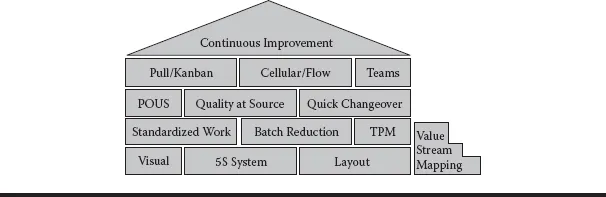

Figure 1.1 House of Lean.

Figure 1.1 depicts the house of Lean that we in the National Institute of Standards and Technology’s Manufacturing Extension Partnership (NIST MEP) have used for years in explaining Lean concepts. The building blocks of the house are some of the Lean tools that most practitioners, in one way or another, have advocated. To be certain, these tools are robust and work well. The “connective tissue” that joins these tools into a cohesive set of practices, however, has gone mostly unnoticed by the Lean community for far too long. Regardless of industry or process, the connective tissue referred to is dependent on the habits of mind that are practiced day in and day out by everyone. These habits of mind, good or bad, predicate the organization’s productivity and ability to adapt and improve successfully.

1.2 Toyota’s Connective Tissue

Arguments can be made asserting that Taiichi Ohno is the father of the Toyota Production System. Regardless, Ohno certainly played a critical role as a participant in the development of Toyota’s strategic objectives. In a meeting between Eliyahu Goldratt and Taiichi Ohno that took place in Chicago in the late 1980s, Ohno admitted to doing his best to confuse American and European visitors to Toyota by focusing on tools, techniques, and the seven wastes while neglecting to fully inform on “his system.”

Ohno stated that he was proud to be Japanese and wanted his country to succeed. He added that he believed that “his system” was a way he could help the nation become modern and industrialized and therefore had no problem sharing Toyota’s insights with other Japanese companies, even Toyota’s biggest competitors. He went on to say, “I was very, very concerned that you Americans and the Europeans would understand what we were doing, copy it, and defeat us in the marketplace.”2

From these statements, it is obvious that Ohno was himself an economic warrior, an industrial samurai of sorts. In the 25 or so years since Goldratt and Ohno’s meeting, most American and European Lean consultants have focused on the elimination of waste. Unfortunately, many of us have not been critical enough to realize that the elimination of waste is the product of the tools that Ohno was happy to share and some other ingredient that he purposely left for us to figure out.

One other telling aspect of Goldratt’s meeting with Ohno that directly relates to what we will share in the coming chapters has to do with Ohno’s method of improvement. When asked why his system worked, Ohno responded that he did not know, only that he kept trying different things, retained what worked, and discarded what didn’t. As we will explain in the next chapter, a spirit of experimentation is all one needs to continually make improvements.3

The spirit of experimentation to be described is the connective tissue of Lean.

1.3 Skills of the Warrior

So what is this “connective tissue” or skill set that the workforce must possess? Recall that skills are different from knowledge. Knowledge, for example, is something you know and can get from seeing, listening, witnessing, or reading. Skill, on the other hand, is something that can only be attained through continued practice.4 We cannot, therefore, merely inform the workforce on how to do something. It must actually be practiced repetitively for it to become a habit of mind. Not only do the Seven Kata define what skills an experienced manager working in a continual improvements environment must have, but they also provide the means for obtaining those skills.

Managers must be able to improve their processes in a practical and immediate way (Improvement Kata5). They must be able to pass on knowledge and skills to each other (Job Instruction Kata,6 Coaching Kata7). They must have people skills to work together (Job Relations Kata8). They must be able to solve problems when problems arise (Problem-Solving Kata9). The need also exists to analyze and improve productivity, efficiency (Job Methods Kata10), and safety conditions (Job Safety Kata11). The one commonality between all seven of these skills is the requirement of repeated practice. The connective tissue previously mentioned comprises these seven skills, the skills of the economic warrior.

Whether the behaviors of the workforce are referred to as policies, standards, procedures, habits of mind, or second nature matters not. Kata are the proven way to instill desired behavior patterns into individuals.12,13 We will explore the relationship between Japanese kata, American ingenuity, and world-class performance. We will then conclude this chapter with a bit of guidance on the suggested approach to this book.

As the word kata may be unfamiliar, a brief explanation is in order. A kata is commonly associated with Japanese martial arts. Specifically, it means form.14 It is what one unfamiliar with martial arts might witness in a neighborhood karate studio: students organized in rows moving uniformly in demonstrating timed strikes (punches and kicks), blocks, and throws. The casual observer might assume that this is done so that the movements come more naturally during actual combat; that would only be partially correct. A kata is also a method for transferring knowledge from the master of a previous generation to students of a future generation.15 This additional feature makes a kata more than just an exercise regimen. It is the conveyance mechanism for skills development as well as a time capsule for the future.

So, in a more minimalist way, the kata can be understood as the performance of a structured daily routine. Individuals who have had some level of involvement in martial arts have told us that a kata is a form, pattern, or type of practice. These descriptions convey much. A form relates contextual differences; there are many kata. A pattern is standardized. Practice indicates repetition. None of these descriptions, however, convey the significance of kata as the cultural modifier that they can be.

A kata is most parochially described by any of the Karate Kid movies. In the original, Ralph Macchio portrays a young impetuous American teenager who wants to learn karate all at once. Pat Morita plays the sensei (master) who directs the student to wax his vehicle. The student becomes incensed with the continual insistence of the sensei to “wax on, wax off,” an unrelenting and seemingly unrelated activity. The repetitive motion becomes one of those learned behaviors that the student ends up relying on during actual combat. Wax on, wax off, a defensive maneuver, became the first kata learned by the student. This is precisely how human beings learn.16 Failure, practice, perfecting, and most of all patience are at the heart of any skill development. It is no different teaching a manager the appropriate application of plan–do–check–act (PDCA) within a kata during their daily improvement or problem-solving activities. In the movie, the impulsive nature of the student had to be conquered, not by the sensei but by the student’s own submission to the kata.

During World War II, the U.S. War Manpower Commission developed the Training Within Industry (TWI) program from which three of the Seven Kata are derived.16 The American statistician Walter A. Shewhart developed PDCA from which the three kata of Toyota Kata have evolved and which have only recently been recognized by Mike Rother.18,19 These methods are all American! Yet it seems that the Japanese are credited with leveraging their power.

We two authors teach many variations of the PDCA cycle as applied to project management, problem solving, and improvement activities. As such, our interpretation of PDCA had typically revolved around its use as a directional rudder. Our access to NIST-MEP training has exposed us to the importance of rapid PDCA cycling by the innovation engineering methods espoused by Doug Hall. One of Hall’s familiar quips, “fail fast, fail cheap,” is a concept that is in total agreement with the Improvement Kata introduced in Chapter 2.20 It is no coincidence that both Hall’s innovation engineering and Rother’s Improvement Kata stress the importance of the successive rapid cycling of PDCA. We now clearly understand the connection between innovation and improvement; they are essentially one and the same. Thus, we recognize the applicability of the Improvement Kata to innovation efforts as an entirely underappreciated feature of Lean. It then should be no surprise why the Toyota Prius was developed so many years ahead of its competition.21

We authors, as TMAC (Texas Manufacturing Assistance Center) field staff, are charged with providing world-class manufacturing practices to Texas’s manufacturing base. As such, we’ve had the unique opportunity of working with a wide variety of organizations. We have worked with multinational corporations that employ in the thousands. We have also worked with family and closely held businesses. Working with a two-person operation isn’t uncommon, and we’ve often worked in industry sectors outside of manufacturing. In more than 25 years of combined industrial extension experience, we have noted the similarities of organizations that seem to easily adopt and successfully exploit best practices and contrasted them to those that never try, stumble, or even give up. By understanding these successes and failures, we acutely appreciate the immediate need for organizations to learn the way of kata.

Leadership is number one. Leadership alone, however, will not suffice. Willingness is important, but learning the seemingly contradictory skills of constructive change and responsible preservation takes more than mandate. The skills of changing (improvement kaizen) and preservation (maintenance kaizen) must be taught uniformly and then practiced daily by management.22 In the chapters that follow, we will explain what role each of the kata play within this concept of a kaizen duality. We also submit that all Seven Kata, to varying degrees, are a vital part of leader standard work.23

Essential elements for success are often boiled down to enlightened leadership, and uniform methods of standardization and improvement. Fortunately, the Seven Kata provide a robust assortment of replicable practices that can quickly achieve simultaneous adaptability and conformity within management’s ranks. Managers must master the disparate skills of adaptability and conformity first. Only then will they be able to use both synergistically.

Lean practices have traditionally been considered to be an extension of Japanese manufacturing techniques in general and elements of the Toyota Production System in particular. Recognizing the advancement of adaptable behavior patterns of these techniques while ignoring the national historical culture of religious syncretism and ritual practice from which they emanated can keep us from fully understanding the “unseen of Lean.”

To understand the application of the Seven Kata, a thumbnail depiction of Japanese history is in order.

1.4 Training Within Industry’s Japanese Connection

During one of our TWI train-the-trainer trainings, Conrad once mentioned to our sensei, Patrick Graupp, that it was good that the Japanese were the ones to conserve TWI because “everything is a ceremony with the Japanese.” Patrick just chuckled. This is an important nuance not to be missed! The TWI courses are for the most part scripted. In today’s PowerPoint-driven training environment, modern training delivery often seems to rely on a cue that a slide may provide the trainer. If more than one trainer uses the same slide deck, learning is dependent on that trainer’s interpretation and level of expertise. Nothing was ever left to chance when the TWI courses were developed in the early 1940s.

“Sticking to the script” was a major directive given to all World War II–era TWI instructors and is still advocated today by the TWI Institute.24 The original World War II training material even states at the bottom of each page, “Do not commit to memory, follow the script.”25 Interestingly, one of our interpretations of kata implies practice, very much a component of effective script delivery. Any experienced TWI instructor will quickly make the connection between their experiences delivering the scripted training of the courses and the concept of kata.

Being collectively party to 10 TWI train-the-trainer sessions, we’ve witnessed prospective trainers try to do it their way, without the benefit of reading the script. In one session, when asked to deliver a certain portion of the Job Relations training, a fellow trainee told senior master trainer Patrick Graupp, “I’ve trained employees for over 25 years, and I’m not about to start boring them to tears by reading to them!” Patrick calmly invited him to do it the way he felt was best. To this fellow’s chagrin, in trying to skim the material as he spoke, he tripped himself up numerous times and even read remarks he had prematurely mentioned. After stumbling through the section, this experienced trainer, new to TWI, immediately understood his mistake and mentioned to Patrick, “I’m going to have to brush up on my out-loud reading skills.”

The Japanese “ritualization,” or strict adherence to the script, was what has preserved TWI’s exacting standards. Exacting training standards is what makes TWI so effective. Ironically, reconstitution of TWI to or above World War II standards might have been impossible without the help of our previous wartime enemy’s safeguarding of this important component of organizational technology.

Conrad’s original remark to Patrick about TWI’s 50-year conservation by the Japanese isn’t that far off the mark. As it turns out, Japan was probably the best place in which TWI training could have simultaneously blossomed while still being preserved. In fact, it was also used sparingly in Europe for the Marshall Plan but didn’t last much into the 1950s.26 Japan is demonstrably a syncretistic culture with more than its share of ritualistic customs. Both syncretism and ritualism have played the essential role in the development and practice of the Seven Kata.

1.5 Lean’s Formula: Syncretism and Ritual

Through much of the Far East history, China has traditionally been at the center of religion, culture, and technology. Japan had historically been at the periphery of their known world. You must stand in China or Korea, west of Japan, to be in “the Land of the Rising Sun.”

As such, Japan has always thrived by duplicating foreign technology, refining it, and eventually integrating it into their culture. This is as true of Japan’s dual religions of Shintoism and Buddhism, as it is of their reputation as first adopters of technology, fashion, and the arts.27 Syncretism goes hand in hand with adaptability. To adopt an alien concept and integrate it into one’s own tradition is a powerful socioeconomic strategy—one that the United States has also demonstrated dexterous ability in.

Another important component of Japanese culture that lends itself to socioeconomic aptitude is the role of rituals. A ritual is procedure’s affluent cousin. A deft application of procedure is the foundation of any healthy operation. Procedures enable standardization, a bulwark of Lean. Standardization is the first order of business in business. Every culture, nonetheless, has ritual. It is a part of being human. Rituals calm and focus thought, enabling reflection. Rituals are kata. They teach and standardize t...

Table of contents

- Cover

- Title Page

- Copyright

- Contents

- Foreword

- Foreword

- Foreword

- Preface

- Acknowledgments

- 1 Weapons for the Economic Warrior

- 2 Improvement Kata: Kaizen

- 3 Nested Job Instruction Kata: Learn to Teach

- 4 Coaching Kata: Teaching to Learn

- 5 Problem-Solving Kata: Seek to Understand Kata

- 6 Job Relations Kata: The Cultural Fortifier

- 7 Job Safety Kata: The Duplex Kata

- 8 Job Methods Kata: Kipling’s Kata

- 9 Submit to the Kata

- Appendix: Lean Training Within Industry (TWI) Timeline

- References

- Biographies

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access The 7 Kata by Conrad Soltero,Patrice Boutier in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.