eBook - ePub

Laser Beam Shaping Applications

- 430 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Laser Beam Shaping Applications

About this book

This new edition details the important features of beam shaping and exposes the subtleties of the theory and techniques that are best demonstrated through proven applications. New chapters cover illumination light shaping in optical lithography; optical micro-manipulation of live mammalian cells through trapping, sorting, and transfection; and laser beam shaping through fiber optic beam delivery. The book discusses applications in lithography, laser printing, optical data storage, stable isotope separation, and spatially dispersive lasers. It also provides a history of the field and includes extensive references.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 |

Introduction

|

The goal of technical publishing in its most basic form is to transfer knowledge. In terms of applications, it is to provide examples of how new technology can be applied within a particular industry to inspire and motivate its further use by others. As the reader goes through this book, there comes a moment where the abstract focuses to a point where ideas merge and one might ask, “Could that work for my application?” The editor’s goals for this book, Laser Beam Shaping Applications (second edition), is threefold: (1) update the information originating in the first edition, (2) explore new applications that have come about during the time period between the two publications, and (3) inspire creativity to drive further innovation within the field.

As engineers and technologists tasked with the implementation of laser technology, we continue to seek optical solutions employing coherent monochromatic beams of light generated by lasers, delivering energy to the work surface with the goal of increasing quality, reliability, and repeatability of processes. Instead of crudely compressing the laser beam into a concentrated spot, laser beam shaping offers techniques capable of finessing and tailoring a process to specific material properties. This ability to fine-tune the process using optical techniques enables a host of material processing tasks to be achieved or improved, including milling, cutting, drilling, welding, and heat treating.

The newer, updated information contained in the second edition has emerged over the past 12 years. It should also be mentioned that the real genesis with laser beam shaping applications within the industry over the past 20 years coincides with and is reinforced by the introduction of the definitive book, Laser Beam Shaping Theory and Techniques (2000, first edition), written by Fred M. Dickey and Scott C. Holswade. It can be said with confidence that the introduction to laser beam shaping theory brought forward the adoption of the technology into the mainstream laser industry and enabled the creation of a host of laser material processes that spurred the further development of products, such as high-density electronics, handheld personal electronic devices, computer miniaturization, and flat panel displays. Most people, if not all, have a large screen flat panel TV, shifted over from flip phones to smartphones, and have acquired a tablet-sized computer. The fact is laser beam shaping has made significant contributions to the quality and capability of these technologies on the factory production line, opening the door to the visualization of and access to data by individuals to a level not seen since the introduction of the first personal computers. It is clear to many of us within the industry that laser beam shaping is no longer new and strange as it was 20–30 years ago. More people throughout the industry are now aware of its potential and familiar with the terms used to describe beam shaping. The second edition of Laser Beam Shaping Applications represents a continuation of the transfer of knowhow to the industry, reiterating its prominence as a means to push the boundaries of laser processing technology.

It will become apparent while reading that topics are discussed within the context of their applications in order to familiarize the reader with the solutions derived for each purpose and in some cases omit many other discussions about the specific details of the theory of laser beam shaping. Such an approach keeps the focus on the potential of the application of laser beam shaping technology and its successful implementation. If a reader wants to delve into a more complete and integrated book on theory, the book, Beam Shaping Theory and Techniques, which is the predecessor to the Laser Beam Shaping Applications is an excellent choice.

In this edition, new and additional chapters will demonstrate clearly that the field of laser beam shaping is an enabler for increasing the stability, quality, and speed of laser-based processes. What becomes evident is that, although the application may change, the concepts described and much of the discussions on the specific approaches continue to stay current and demonstrate the longevity, adaptability, and transferability of laser beam shaping. The editors are pleased to acknowledge that Chapters 2, 3, and 7 have been revised by their respective authors to include updates and further work realized since the last printing. Chapters 4, 10, 11, and 12 are included without revisions and although they do not contain updated material, each still provides a unique perspective on technologies and applications that are still relevant today. Chapter 4 addresses beam shaping for excimer lasers, covering varying integrator and prismatic-based homogenizer beam shaper designs of interest to the industry for bulk material removal, using ablation techniques and precision micromachining. Chapters 5, 8, and 9 cover entirely new areas as well as new applications, which include beam shaping using micro-optical elements for illumination in lithography work, through the use of shaped fiber optics, and the use of beam shaping for optical tweezers. Chapter 10 treats the application of deformable mirrors and explains their method of actively shaping higher powered laser beams due to the segmentation of actuators under a deformable substrate. Chapter 11 is an example of the application of spectral control in dispersive lasers. Each of these chapters provides the reader with ample opportunities to compare and contrast applications.

A great comparative example is included in the updated Chapter 2, “Illuminators in Microlithography,” written by Paul Michaloski, and Chapter 3, “Laser Beam Shaping in Array-Type Laser Printing Systems,” written by Andrew Kurtz, Daniel Haas, and Nissim Pilossof. Each chapter reveals that two applications that occupy either end of a product spectrum can benefit from similar laser beam shaping technology. Both chapters offer insights into the use of fly’s eye uniformizers, also known as fly’s eye homogenizers, or refractive integrators as well as the use of kaleidoscope or light pipe design for homogenization of laser beams. Each application describes the clear benefits from the two styles of integrator designs in relation to their respective technology areas and provides the reader the opportunity to recognize how the technology can be leveraged within the two such diverse cases.

Chapter 12, “Beam Shaping: A Review,” written by Fred M. Dickey and Scott C. Holswade, continues to provide an excellent base foundation for the readers who are new to the field of laser beam shaping. What makes Chapter 12 useful to a novice and to those actually engaged in the technology is that it provides foundational material in a manner that clarifies and assures the reader that as he or she reads other chapters, he or she will have the basics to clearly and concisely understand the opportunities as well as the difficulties that are associated with beam shaping.

New to this edition, Chapter 5, “Micro-Optics Is Key Enabling Technology for Illumination Light Shaping in Photolithography,” written by Reinhardt Voelkel, expands on a similar theme as Chapter 2; however, it introduces the use of monolithic wafer-based refractive micro-optics and vividly describes their use in a host of lithographic illumination techniques. Chapter 5 further expands on the natural evolution of established lens array integrators over the past years and demonstrates the importance of hybridization of established techniques and the evolution of integrators as they began to take the form of monolithic wafer-based micro-optical elements. Section 5.2.3 with the introduction of Kohler integrators that were utilized for early lithographic tools in the 1970s provides a splendid historical perspective on why the need for continued development of illumination in some cases drove the development of micro-optical fabrication techniques that transformed today’s lithography industry. Chapter 8, “Applications of Diffractive Optics Elements in Optical Trapping,” written by Ruben Ramos-Garcia, Victor Arrizon, and Ulises Ruiz, provides a primer for the broader role of spatial light modulators within this field and the use of diffractive optical elements. Chapter 8 serves as a basic building block for the value of laser beam shaping within the field of optical tweezers or trapping while recognizing the different degrees of technical sophistication of the intended reader. Chapter 9, “Laser Beam Shaping through Fiber Optic Beam Delivery,” written by Todd Lizotte and Orest Ohar, demonstrates that light pipes adapted into smaller form factors, such as drawn square fibers, can open doors to new laser materials processing applications for precision material removal and offer laser beam shaping opportunities for more traditional robotic based fiber optic based processes. Chapter 9 provides the reader with an existing robotic example on a production floor to emphasize the concepts governing the application and to demonstrate the true nature of a product that incorporates laser beam shaping technology.

Considering these new and revised chapters, it becomes apparent that solutions in each individual industry continue to evolve as beam shaping technology and fabrication techniques improve, and/or newer technologies emerge. From the chapters added to this new edition, the reader can ponder the evolution of beam integrators over time and witness the shift from the basics of light pipes and the early days of refractive integrators to the modern versions that leverage micro-optical technology.

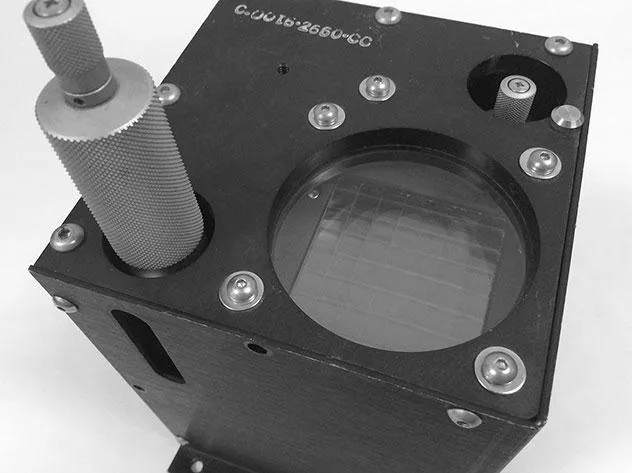

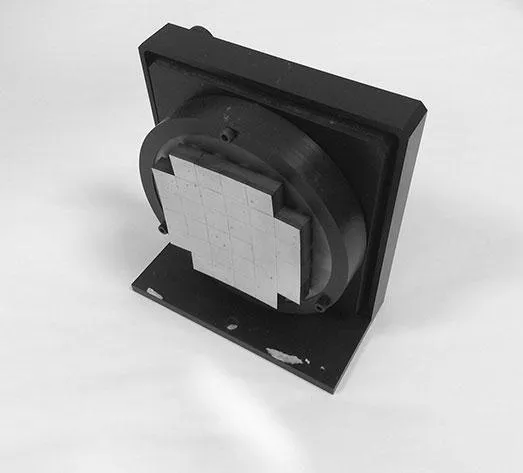

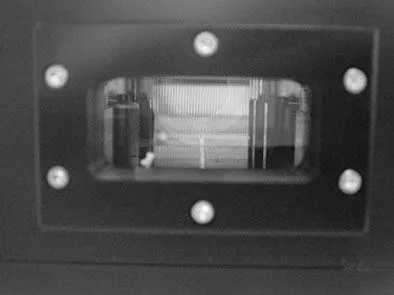

The theory of laser beam shaping is bound within the constraints of physics and calculations, whereas applications provide a tangible point in time to gauge the progress of a technology, within real terms of its proven limitations at that moment in time, including in some cases, the lack of computing power, access to the most efficient optical materials, and the basic state of fabrication techniques used to realize the final application. Each chapter could be considered a historical marker. As an example, take optical integrators back in the late 1970s and early 1980s, at that time cylindrical and spherical refractive lens and reflective mirror integrators began to find traction within the burgeoning laser industry. Made by stacking individual lenses (spherical or cylindrical) or faceted mirror segments, the lens array integrators were expensive and somewhat clumsy to use and replicate (Figures 1.1 and 1.2). Approximately 15 years ago, such devices began to take the form of reactively ion-etched monolithic refractive lens arrays (Figure 1.3), which also came with their own limitations, including part-to-part reproducibility and alignment. Ultimately, through continued fabrication development, these monolithic micro-optical arrays reduced the cost of the beam shaper designs and allowed the technology to leap into other markets, such as printing, telecom, and laser-material processing. Each chapter provides the reader a clear vantage point to evaluate the evolution of beam shaping technology and weigh its progress. There are times, however, where even the older designs become more relevant to today’s needs or industrial demands on a true production floor. Even stacked lens array integrators continue to find relevance within the latest generation of laser processing systems for large panel displays as they continue producing cutting edge products that consumers purchase every day.

FIGURE 1.1 Refractive lens array homogenizer, circa 1985.

FIGURE 1.2 Reflective segmented mirror array homogenizer, circa 1990.

FIGURE 1.3 Refractive monolithic lens array homogenizer, circa 2008.

It is evident in the growth of laser beam shaping that even though the solutions are specific within this book, they may be applied in different ways to other applications in the future. Even though these chapters represent some of the most understood techniques within the industry, each of them can be enhanced, modified, or combined to tackle the next challenge faced within an industry that continues to leverage laser technology.

The editors thank the authors who submitted new and revised chapters to this edition and add that as with most books, no editor or author can ever be completely right, although they all strive for that level of perfection. The editors shall be grateful for any comments, corrections, or criticisms that readers may find relevant and bring to their attention.

2 | Illuminators for Microlithography |

CONTENTS

2.1 Introduction

2.2 Illuminators in Microlithography

2.2.1 The Path of Microlithography

2.2.2 Description of an Exposure

2.2.2.1 Exposure

2.2.2.2 Uniformity

2.2.2.3 Alignment

2.2.2.4 Telecentricity

2.2.3 Overview of Projection Optics and Imaging Concerns

2.2.4 The Role of Illumination Pupil Distributions

2.2.4.1 Partial Coherence

2.2.4.2 Types of Lithographic Features

2.2.4.3 Of...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface

- Editors

- Contributors

- Chapter 1 Introduction

- Chapter 2 Illuminators for Microlithography

- Chapter 3 Laser Beam Shaping in Array-Type Laser Printing Systems

- Chapter 4 Practical UV Excimer Laser Image System Illuminators

- Chapter 5 Micro-Optics for Illumination Light Shaping in Photolithography

- Chapter 6 Beam Shaping for Optical Data Storage

- Chapter 7 Laser Isotope Separation with Shaped Light

- Chapter 8 Applications of Diffractive Optics Elements in Optical Trapping

- Chapter 9 Laser Beam Shaping through Fiber Optic Beam Delivery

- Chapter 10 Laser Beam Shaping by Means of Flexible Mirrors

- Chapter 11 Application of Laser Beam Shaping for Spectral Control of “Spatially Dispersive” Lasers

- Chapter 12 Beam Shaping: A Review

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Laser Beam Shaping Applications by Fred M. Dickey, Todd E. Lizotte, Fred M. Dickey,Todd E. Lizotte in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Electrical Engineering & Telecommunications. We have over one million books available in our catalogue for you to explore.